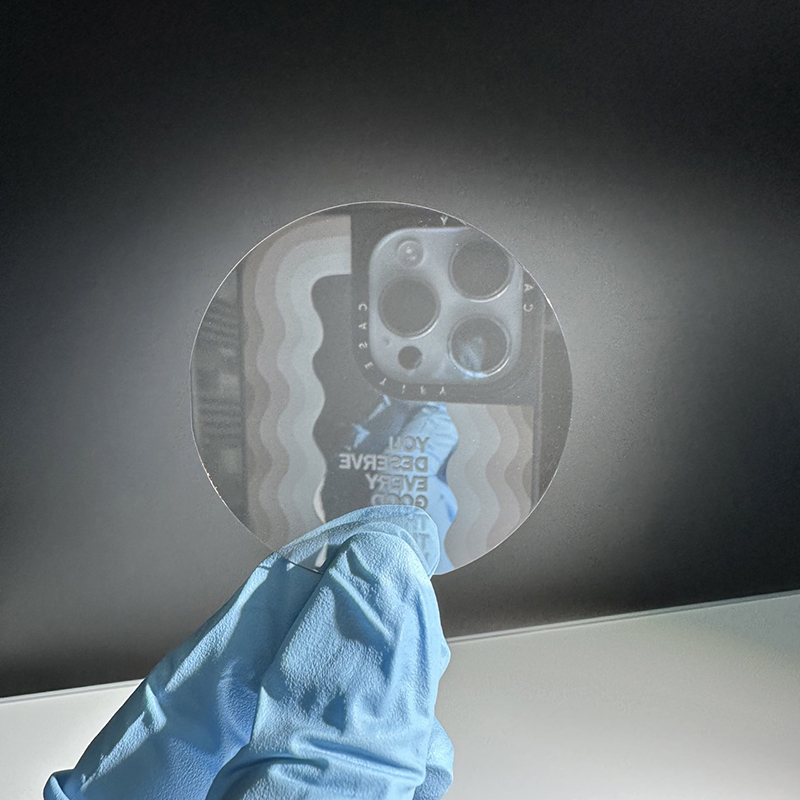

4inch Semi-insulting SiC wafers HPSI SiC substrate Prime Production grade

Product Specification

Silicon carbide (SiC) is a compound semiconductor material composed of the elements carbon and silicon, and is one of the ideal materials for making high-temperature, high-frequency, high-power and high-voltage devices. Compared with the traditional silicon material (Si), the forbidden band width of silicon carbide is three times that of silicon; the thermal conductivity is 4-5 times that of silicon; the breakdown voltage is 8-10 times that of silicon; and the electron saturation drift rate is 2-3 times that of silicon, which meets the needs of the modern industry for high-power, high-voltage, and high-frequency, and it is mainly used to make high-speed, high-frequency, high-power and light-emitting electronic components, and its downstream application areas include smart grid, New energy vehicles, photovoltaic wind power, 5G communications, etc. In the field of power devices, silicon carbide diodes and MOSFETs have begun to be commercially applied.

Advantages of SiC wafers/SiC substrate

High temperature resistance. The forbidden band width of silicon carbide is 2-3 times that of silicon, so electrons are less likely to jump at high temperatures and can withstand higher operating temperatures, and the thermal conductivity of silicon carbide is 4-5 times that of silicon, making it easier to dissipate heat from the device and allowing for a higher limiting operating temperature. The high-temperature characteristics can significantly increase the power density, while reducing the requirements for the heat dissipation system, making the terminal more lightweight and miniaturised.

High voltage resistance. Silicon carbide's breakdown field strength is 10 times that of silicon, enabling it to withstand higher voltages, making it more suitable for high-voltage devices.

High-frequency resistance. Silicon carbide has two times the saturation electron drift rate of silicon, resulting in its devices in the shutdown process does not exist in the current drag phenomenon, can effectively improve the device switching frequency, to achieve device miniaturisation.

Low energy loss. Silicon carbide has a very low on-resistance compared to silicon materials, low conduction loss; at the same time, the high bandwidth of silicon carbide significantly reduces the leakage current, power loss; in addition, silicon carbide devices in the shutdown process does not exist in the current drag phenomenon, low switching loss.

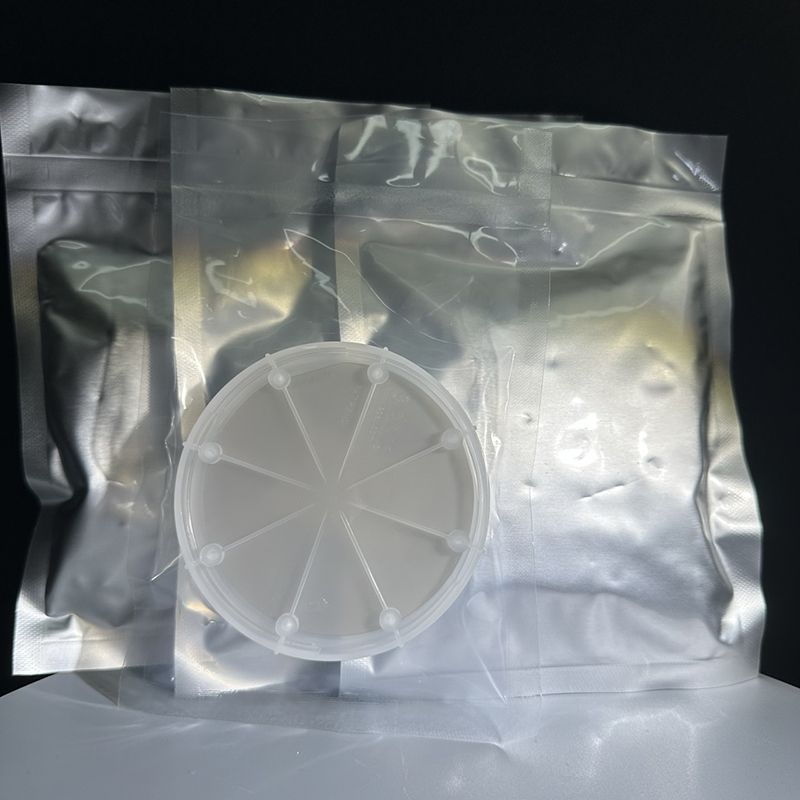

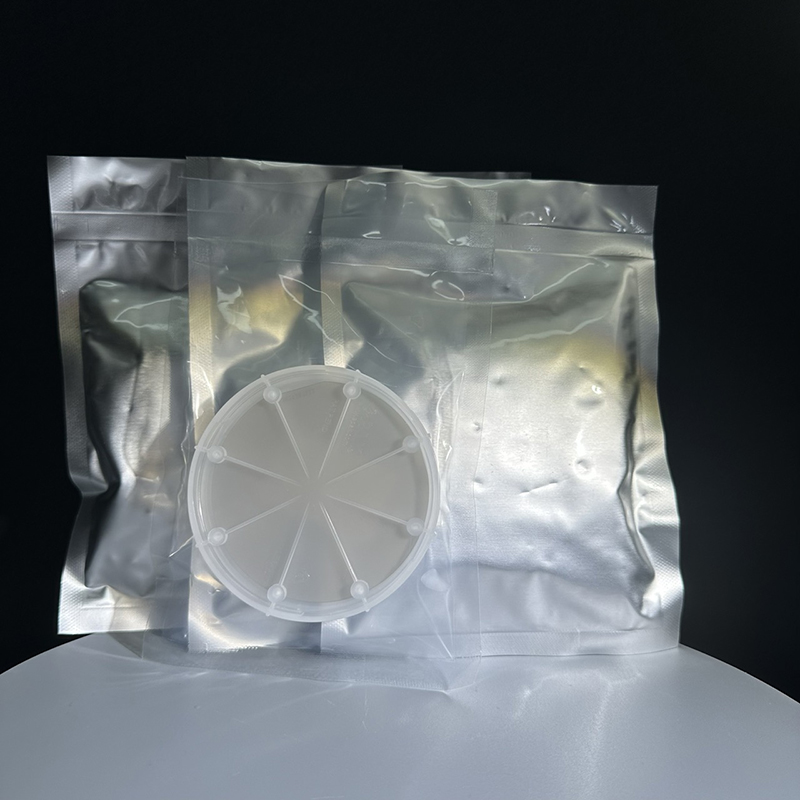

Detailed Diagram