Silicon Carbide SiC Ceramic Fork Arm/Hand for Critical Handling Systems

Detailed Diagram

Introduce of Silicon Carbide Ceramic Fork Arm/Hand

The Silicon Carbide Ceramic Fork Arm/Hand is a cutting-edge component developed for advanced industrial automation, semiconductor processing, and ultra-clean environments. Its distinct forked architecture and ultra-flat ceramic surface make it ideal for handling delicate substrates, including silicon wafers, glass panels, and optical devices. Engineered with precision and manufactured from ultra-pure silicon carbide, the Silicon Carbide Ceramic Fork Arm/Hand offers unmatched mechanical strength, thermal reliability, and contamination control.

Unlike conventional metal or plastic arms, the Silicon Carbide Ceramic Fork Arm/Hand delivers stable performance in extreme thermal, chemical, and vacuum conditions. Whether operating in a Class 1 cleanroom or within a high-vacuum plasma chamber, this component ensures safe, efficient, and residue-free transport of valuable parts.

With a structure tailored for robotic arms, wafer handlers, and automated transfer tools, the Silicon Carbide Ceramic Fork Arm/Hand is a smart upgrade for any high-precision system.

Manufacturing Process of Silicon Carbide Ceramic Fork Arm/Hand

Crafting a high-performance Silicon Carbide Ceramic Fork Arm/Hand involves a tightly controlled ceramic engineering workflow that ensures repeatability, reliability, and ultra-low defect rates.

1. Material Engineering

Only ultra-high-purity silicon carbide powder is used in the fabrication of the Silicon Carbide Ceramic Fork Arm/Hand, ensuring low ionic contamination and high bulk strength. The powders are precisely blended with sintering additives and binders to achieve optimal densification.

2. Forming the Base Structure

The base geometry of the fork arm/hand is formed using cold isostatic pressing or injection molding, which ensures high green density and uniform stress distribution. The U-shape configuration is optimized for stiffness-to-weight ratio and dynamic response.

3. Sintering Process

The green body of the Silicon Carbide Ceramic Fork Arm/Hand is sintered in a high-temperature, inert gas furnace at over 2000°C. This step ensures near-theoretical density, producing a component that resists cracking, warping, and dimensional deviation under real-world thermal loads.

4. Precision Grinding and Machining

Advanced CNC diamond tooling is used to shape the final dimensions of the Silicon Carbide Ceramic Fork Arm/Hand. Tight tolerances (±0.01 mm) and mirror-level surface finish reduce particulate release and mechanical stress.

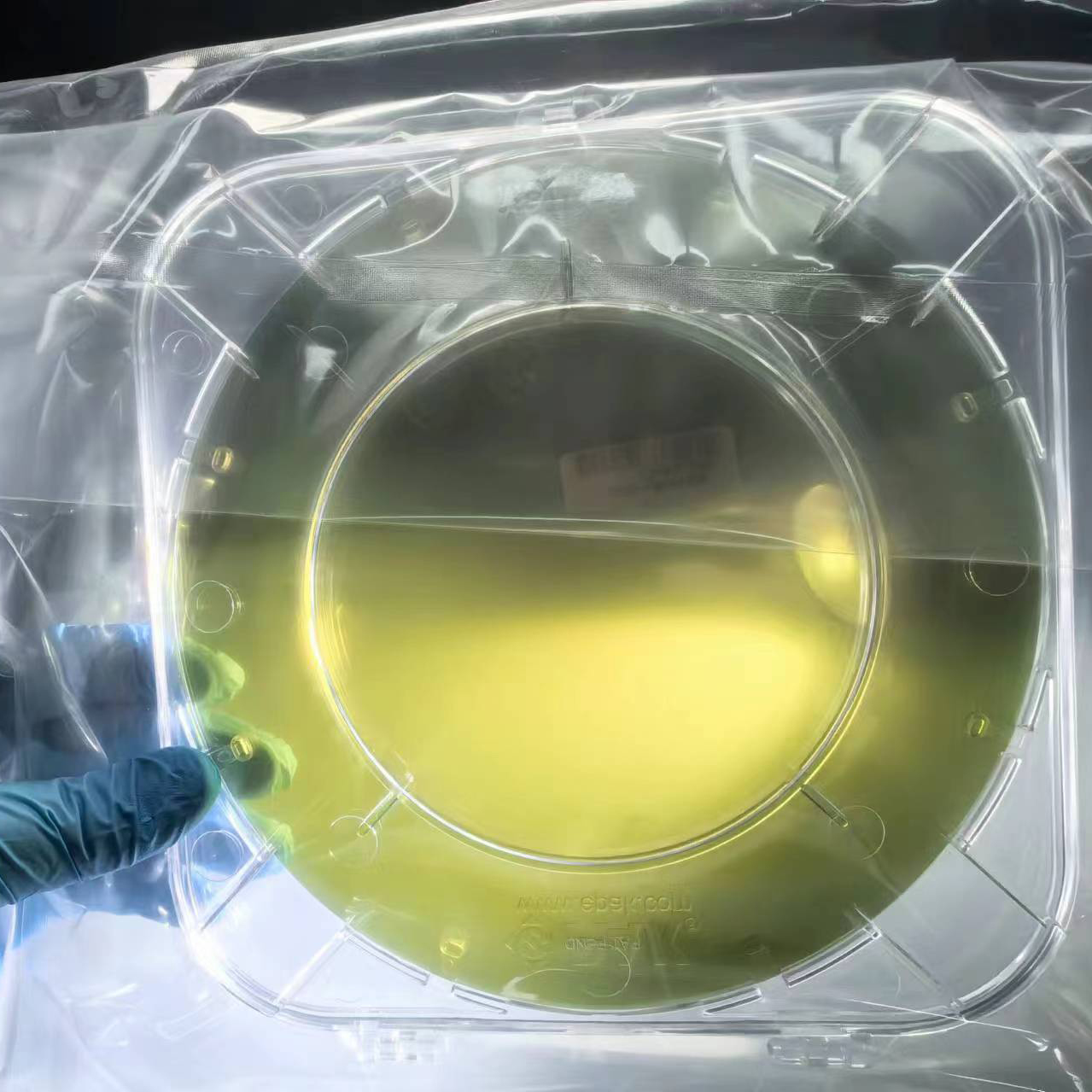

5. Surface Conditioning and Cleaning

Final surface finishing includes chemical polishing and ultrasonic cleaning to prepare the fork arm/hand for direct integration in ultra-clean systems. Optional coatings (CVD-SiC, anti-reflective layers) are also available.

This meticulous process guarantees that each Silicon Carbide Ceramic Fork Arm/Hand meets the most stringent industrial standards, including SEMI and ISO cleanroom requirements.

Paramete of Silicon Carbide Ceramic Fork Arm/Hand

| Item | Test Conditions | Data | Unit |

| Silicon Carbide Content | / | >99.5 | % |

| Average Grain Size | / | 4-10 | micron |

| Density | / | >3.14 | g/cm3 |

| Apparent Porosity | / | <0.5 | Vol % |

| Vickers Hardness | HV0.5 | 2800 | Kg/mm2 |

| Modulus Of Rupture (3 Points) | Test bar size:3 x 4 x 40mm | 450 | MPa |

| Compression Strength | 20°C | 3900 | MPa |

| Modulus Of Elasticity | 20°C | 420 | GPa |

| Fracture Toughness | / | 3.5 | MPa/m1/2 |

| Thermal Conductivity | 20°C | 160 | W/(mK) |

| Electrical Resistivity | 20°C | 106-108 | Ωcm |

| Coefficient of Thermal Expansion | 20°C-800°C | 4.3 | K-110-6 |

| Max. Application Temperature | Oxide Atmosphere | 1600 | °C |

| Max. Application Temperature | Inert Atmosphere | 1950 | °C |

Applications of Silicon Carbide Ceramic Fork Arm/Hand

The Silicon Carbide Ceramic Fork Arm/Hand is designed for use in high-precision, high-risk, and contamination-sensitive applications. It enables reliable handling, transfer, or support of critical components with zero compromise.

➤ Semiconductor Industry

-

Used as a robotic fork in front-end wafer transfer and FOUP stations.

-

Integrated into vacuum chambers for plasma etching and PVD/CVD processes.

-

Functions as a carrier arm in metrology and wafer alignment tools.

The Silicon Carbide Ceramic Fork Arm/Hand eliminates electrostatic discharge (ESD) risks, supports dimensional precision, and resists plasma corrosion.

➤ Photonics and Optics

-

Supports delicate lenses, laser crystals, and sensors during fabrication or inspection.

Its high stiffness prevents vibration, while the ceramic body resists contamination of optical surfaces.

➤ Display and Panel Production

-

Handles thin glass, OLED modules, and LCD substrates during transport or inspection.

The flat and chemically inert Silicon Carbide Ceramic Fork Arm/Hand protects against scratching or chemical etching.

➤ Aerospace and Scientific Instruments

-

Utilized in satellite optics assembly, vacuum robotics, and synchrotron beamline setups.

Performs flawlessly in space-grade cleanrooms and radiation-prone environments.

In each field, the Silicon Carbide Ceramic Fork Arm/Hand enhances system efficiency, reduces part failure, and minimizes downtime.

FAQ – Frequently Asked Questions of Silicon Carbide Ceramic Fork Arm/Hand

Q1: What makes the Silicon Carbide Ceramic Fork Arm/Hand better than metal alternatives?

The Silicon Carbide Ceramic Fork Arm/Hand has superior hardness, lower density, better chemical resistance, and significantly less thermal expansion than metals. It is also cleanroom-compatible and free from corrosion or particle generation.

Q2: Can I request custom dimensions for my Silicon Carbide Ceramic Fork Arm/Hand?

Yes. We offer complete customization, including fork width, thickness, mounting holes, cutouts, and surface treatments. Whether for 6", 8", or 12" wafers, your fork arm/hand can be tailored to fit.

Q3: How long does the Silicon Carbide Ceramic Fork Arm/Hand last under plasma or vacuum?

Thanks to the high-density SiC material and inert nature, the fork arm/hand remains functional even after thousands of process cycles. It shows minimal wear under aggressive plasma or vacuum heat loads.

Q4: Is the product suitable for ISO Class 1 cleanrooms?

Absolutely. The Silicon Carbide Ceramic Fork Arm/Hand is manufactured and packaged in certified cleanroom facilities, with particle levels well below ISO Class 1 requirements.

Q5: What is the maximum operating temperature for this fork arm/hand?

The Silicon Carbide Ceramic Fork Arm/Hand can operate continuously at up to 1500°C, making it suitable for direct use in high-temperature process chambers and thermal vacuum systems.

These FAQs reflect the most common technical concerns from engineers, lab managers, and system integrators using the Silicon Carbide Ceramic Fork Arm/Hand.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.