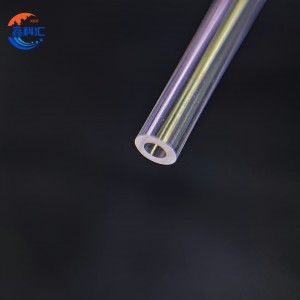

Sapphire Capillary Tubes

Detailed Diagram

Introduction of Sapphire Capillary Tubes

Sapphire Capillary Tubes are precision-engineered hollow components made from single-crystal aluminum oxide (Al₂O₃), offering exceptional mechanical strength, optical clarity, and chemical resistance. These ultra-durable tubes are designed for applications that demand high temperature tolerance, inertness, and dimensional precision, such as microfluidics, spectroscopy, and semiconductor manufacturing. Their smooth inner surface and excellent hardness (Mohs 9) ensure consistent performance in environments where glass or quartz tubes are not sufficient.

Sapphire Capillary Tubes are particularly suited for applications that require high chemical purity and mechanical resilience. The unmatched hardness of sapphire makes these tubes highly scratch-resistant and wear-resistant. Their biocompatibility further enables their use in biomedical and pharmaceutical fluid systems. They also demonstrate minimal thermal expansion, which ensures dimensional stability under fluctuating temperatures, making them ideal for high-vacuum and high-heat systems.

Manufacturing Principle of Sapphire Capillary Tubes

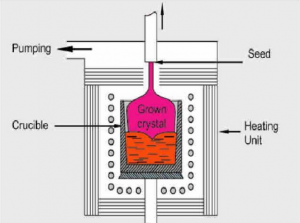

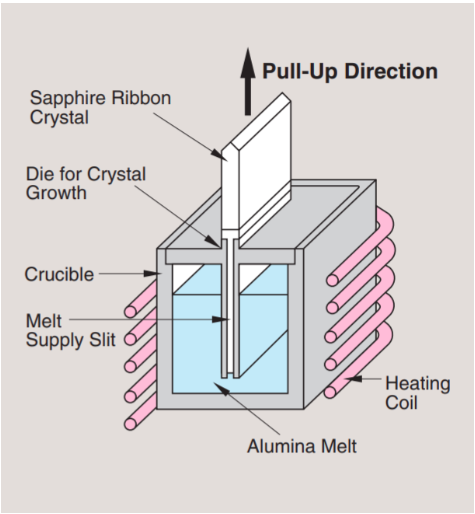

Sapphire Capillary Tubes are primarily manufactured through two distinct methods: the Kyropoulos (KY) method and the Edge-defined Film-fed Growth (EFG) method.

In the KY method, high-purity aluminum oxide is melted in a crucible and allowed to crystallize around a seed crystal. This slow and controlled growth process yields large sapphire boules with exceptional clarity and low internal stress. The resulting cylindrical crystal is then oriented, cut, and processed using diamond saws and ultrasonic tools to achieve the desired tube dimensions. The bore is created through precision coring or laser drilling, followed by internal polishing to meet the exacting requirements of the application. This method is ideal for producing tubes with optical-grade inner surfaces and tight tolerances.Especially Sapphire Capillary Tubes.

The EFG method, on the other hand, allows the direct pulling of pre-shaped hollow sapphire tubes from the melt using a die. While EFG tubes may not offer the same level of internal polish as KY tubes, they allow for continuous production of long capillaries with uniform cross-sections, reducing material waste and machining time. This method is more cost-efficient for producing technical-grade tubes used in industrial or structural applications.Especially Sapphire Capillary Tubes.

Both methods are followed by precision machining, grinding, ultrasonic cleaning, and multi-stage inspection to ensure that every Sapphire Capillary Tube meets high-quality standards.

Applications of Sapphire Capillary Tubes

- Medical Diagnostics: Sapphire Capillary Tubes are used in blood analyzers, microfluidic devices, DNA sequencing systems, and clinical diagnostic platforms. Their chemical inertness ensures accurate, uncontaminated fluid flow in sensitive environments.

- Optical and Laser Systems: Due to sapphire's excellent transmission in the UV to IR range, these tubes are used in laser delivery systems, fiber optic protection, and as light-guiding channels. Their hardness and thermal stability help maintain alignment and transmission quality under stress.

- Semiconductor Fabrication: These tubes handle high-purity gases and reactive chemicals in plasma etching, CVD, and deposition chambers. Their resistance to corrosion and thermal shock supports high-precision processing.

- Analytical Chemistry: In chromatography, spectroscopy, and trace analysis, Sapphire Capillary Tubes ensure minimal sample adsorption, stable fluid transport, and resistance to aggressive solvents.

- Aerospace and Defense: Used for optical sensing, fluid management, and pressure control in high-G, high-temperature, and vibration-heavy environments.

- Energy and Industrial Systems: Suitable for transporting corrosive fluids and gases in petrochemical plants, power generation facilities, and high-efficiency fuel cells.

FAQ of Sapphire Capillary Tubes

-

Q1: What are Sapphire Capillary Tubes made of?

A: They are made from synthetic single-crystal aluminum oxide (Al₂O₃), commonly known as sapphire, with a purity of 99.99%.Q2: What size options are available?

A: Standard inner diameters range from 0.1 mm to 3 mm, with outer diameters from 0.5 mm to over 10 mm. Custom sizes are also available.Q3: Are the tubes optically polished?

A: Yes, KY-grown tubes can be optically polished on the inside, making them suitable for optical or fluidic systems requiring minimal resistance or maximum transmission.Q4: What temperature can Sapphire Capillary Tubes withstand?

A: They can operate continuously above 1600°C in inert or vacuum environments and resist thermal shock better than glass or quartz.Q5: Are the tubes suitable for biomedical applications?

A: Absolutely. Their biocompatibility, chemical stability, and sterility make them ideal for medical devices and clinical diagnostics.Q6: What is the lead time for custom orders?

A: Depending on complexity, custom Sapphire Capillary Tubes usually require 2–4 weeks for production and QA.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.