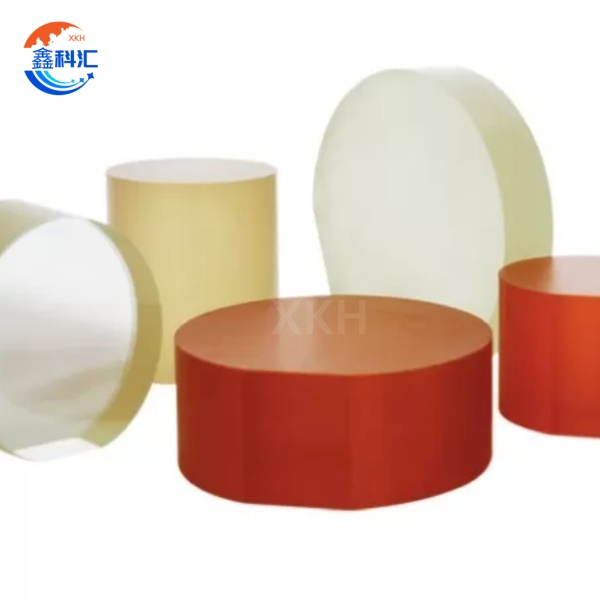

Mg-Doped LiNbO₃Ingots 45°Z-Cut 64°Y-Cut Orientations For 5G/6G Communication Systems

Technical parameters

| Crystal structure | Hexagonal |

| Lattice constant | a = 5.154 Å c = 13.783 Å |

| Mp | 1650 o C |

| Density | 7.45 g / cm3 |

| Curie temperature | 610 o C |

| Hardness | 5.5 - 6 Mohs |

| Thermal expansion coefficient | aa = 1.61 x 10 -6 / k ac = 4.1 x 10 -6 / k |

| Resistivity | 1015 Wm |

| Permittivity | es11 / e0: 39 ~ 43 es33 / e0: 42 ~ 43 et11 / e0: 51 ~ 54 et11 / e0: 43 ~ 46 |

| Color | Colorless |

| Through a range of | 0.4 ~ 5.0 um |

| Index of refraction | n o = 2.176 n e = 2.180 @ 633 nm |

Key Technical Characteristics

LiNbO3 Ingot exhibits a suite of superior properties:

1. Electro-Optic Performance:

High Nonlinear Coefficient: d₃₃= 34.4 pm/V, enabling efficient second harmonic generation (SHG) and optical parametric oscillation (OPO) for tunable infrared sources .

Broadband Transmission: Minimal absorption in the visible spectrum (α < 0.1 dB/cm at 1550 nm), critical for C-band optical amplifiers and quantum frequency conversion .

2. Mechanical & Thermal Robustness:

Low Thermal Expansion: CTE = 14.4×10⁻⁶/K (a-axis), ensuring compatibility with silicon substrates in hybrid photonic circuits .

High Piezoelectric Response: g₃₃> 20 mV/m, ideal for surface acoustic wave (SAW) filters in 5G mmWave systems .

3. Defect Control:

Micropipe Density: <0.1 cm⁻²(8-inch ingots), validated via synchrotron X-ray diffraction .

Radiation Resistance: Minimal lattice distortion under 100 kV/cm electric fields, validated in aerospace-grade testing .

Strategic Applications

LiNbO3 Ingotdrives innovation across cutting-edge domains:

1. Quantum Photonics:

Single-Photon Sources: Leveraging nonlinear down-conversion, LiNbO3 enables entangled photon pair generation for quantum key distribution (QKD) systems .

Quantum Memory: Integration with Er³⁺-doped fibersachieves 30% storage efficiency at 1530 nm, critical for long-distance quantum networks .

2. Optoelectronic Systems:

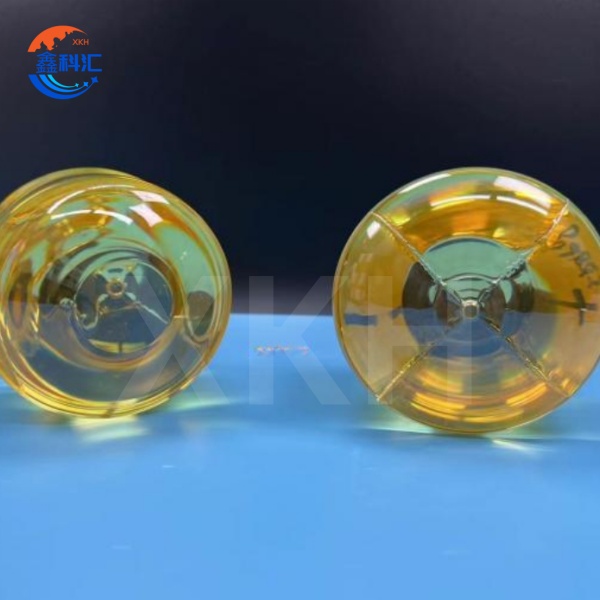

High-Speed Modulators: X-cut LiNbO3 achieves 40 GHz bandwidth with <1 dB insertion loss, outperforming LiTaO3 in 400G optical transceivers .

Laser Frequency Doubling: Mg-doped LiNbO3 (6% threshold) reduces photorefractive damage, enabling stable 1064 nm → 532 nm conversion in LiDAR systems .

3. Industrial Sensing:

High-Temperature Pressure Sensors: Operate continuously at 600°C, leveraging piezoelectric resonance for oil/gas pipeline monitoring .

Current Transformers: Fe/Mg co-doping enhances sensitivity (0.1% FS) in smart grid applications .

XKH Services & Solutions

Our LiNbO3 Ingot services are engineered for scalability and precision:

1. Custom Fabrication:

Size Options: 3–8-inch ingots with X/Y/Z-cut and 42°Y-cut geometries, ±0.01° angular tolerance .

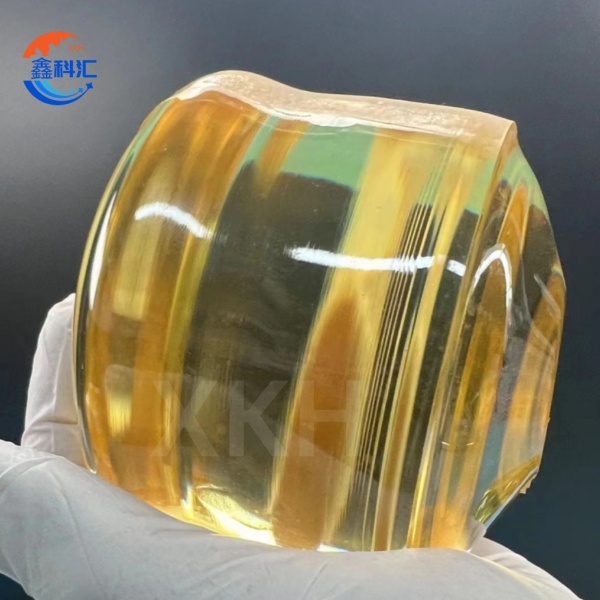

Doping Control: Fe/Mg co-doping via Czochralski method (concentration range 10¹⁶–10¹⁹ cm⁻³) to optimize photorefractive resistance .

2. Advanced Processing:

Heterogeneous Integration: Si-LN composite wafers (300–600 nm thickness) with thermal conductivity up to 8.78 W/m·K for high-frequency SAW filters .

Waveguide Fabrication: Proton exchange (PE) and reverse proton exchange (RPE) techniques yield submicron waveguides (Δn >0.7) for 40 GHz electro-optic modulators .

3. Quality Assurance:

End-to-End Testing: Raman spectroscopy (polytype verification), XRD (crystallinity), and AFM (surface morphology) ensure compliance with MIL-PRF-4520J and JEDEC-033 .

Global Logistics: Temperature-controlled shipping (±0.5°C) and 48-hour emergency delivery across Asia-Pacific, Europe, and North America .

Competitive Advantages

1. Cost Efficiency: 8-inch ingots reduce material waste by 30% compared to 4-inch alternatives, lowering per-unit costs by 18% .

2. Performance Metrics:

SAW Filter Bandwidth: >1.28 GHz (vs. 0.8 GHz for LiTaO3), critical for 5G mmWave bands .

Thermal Cycling: Survives -200–500°C cycles with <0.05% warpage, validated in automotive LiDAR testing .

1. Sustainability: Recyclable processing methods reduce water consumption by 40% and energy use by 25%.

Conclusion

LiNbO3 Ingot remains the material of choice for next-generation optoelectronics, combining unmatched electro-optic performance with industrial-grade reliability. From quantum computing to 6G communications, its versatility and scalability position it as a critical enabler of future technologies. Partner with us to leverage cutting-edge doping, defect mitigation, and heterogeneous integration solutions tailored to your application needs.