Ion Beam Polishing Machine for sapphire SiC Si

Detailed Diagram

Product Overview of Ion Beam Polishing Machine

The Ion Beam Figuring and Polishing Machine is based on the principle of ion sputtering. Inside a high-vacuum chamber, an ion source generates plasma, which is accelerated into a high-energy ion beam. This beam bombards the surface of the optical component, removing material at the atomic scale to achieve ultra-precise surface correction and finishing.

As a non-contact process, ion beam polishing eliminates mechanical stress and avoids subsurface damage, making it ideal for manufacturing high-precision optics used in astronomy, aerospace, semiconductors, and advanced research applications.

Working Principle of Ion Beam Polishing Machine

Ion Generation

Inert gas (e.g., argon) is introduced into the vacuum chamber and ionized through an electrical discharge to form plasma.

Acceleration & Beam Formation

The ions are accelerated to several hundred or thousand electron volts (eV) and shaped into a stable, focused beam spot.

Material Removal

The ion beam physically sputters atoms from the surface without initiating chemical reactions.

Error Detection & Path Planning

Surface figure deviations are measured with interferometry. Removal functions are applied to determine dwell times and generate optimized tool paths.

Closed-Loop Correction

Iterative cycles of processing and measurement continue until RMS/PV precision targets are achieved.

Key Features of Ion Beam Polishing Machine

Universal Surface Compatibility – Processes flat, spherical, aspherical, and freeform surfaces

Ultra-Stable Removal Rate – Enables sub-nanometer figure correction

Damage-Free Processing – No subsurface defects or structural changes

Consistent Performance – Works equally well on materials of varying hardness

Low/Medium Frequency Correction – Eliminates errors without generating mid/high-frequency artifacts

Low Maintenance Requirement – Long continuous operation with minimal downtime

Main Technical Specifications of Ion Beam Polishing Machine

|

Item |

Specification |

| Processing Method | Ion sputtering in a high-vacuum environment |

| Processing Type | Non-contact surface figuring & polishing |

| Max Workpiece Size | Φ4000 mm |

| Motion Axes | 3-axis / 5-axis |

| Removal Stability | ≥95% |

| Surface Accuracy | PV < 10 nm; RMS ≤ 0.5 nm (typical RMS < 1 nm; PV < 15 nm) |

| Frequency Correction Capability | Removes low–medium frequency errors without introducing mid/high frequency errors |

| Continuous Operation | 3–5 weeks without vacuum maintenance |

| Maintenance Cost | Low |

Processing Capabilities of Ion Beam Polishing Machine

Supported Surface Types

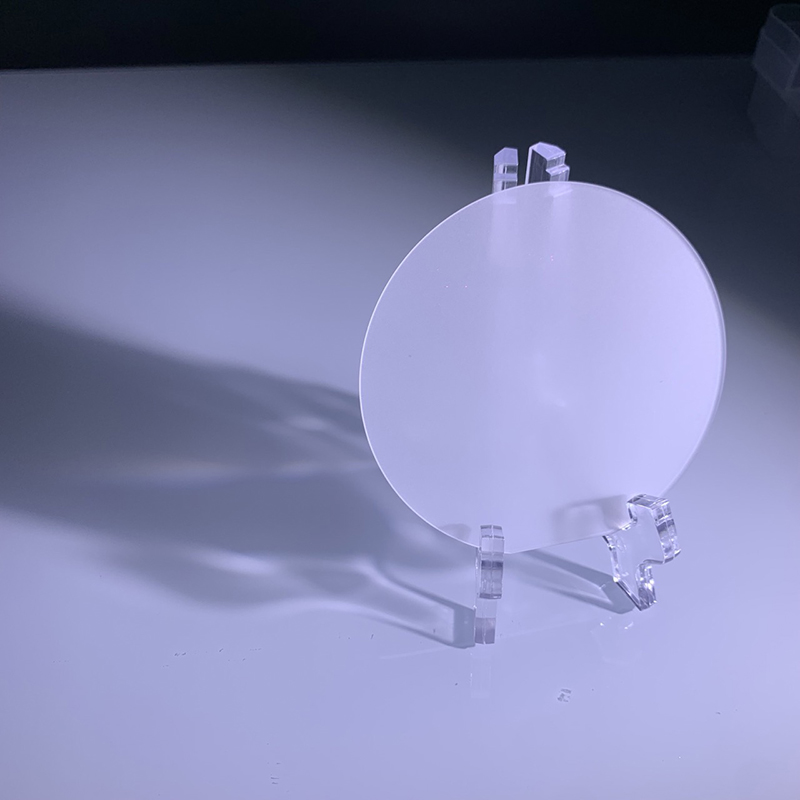

Simple: Flat, spherical, prism

Complex: Symmetric/asymmetric asphere, off-axis asphere, cylindrical

Special: Ultra-thin optics, slat optics, hemispherical optics, conformal optics, phase plates, freeform surfaces

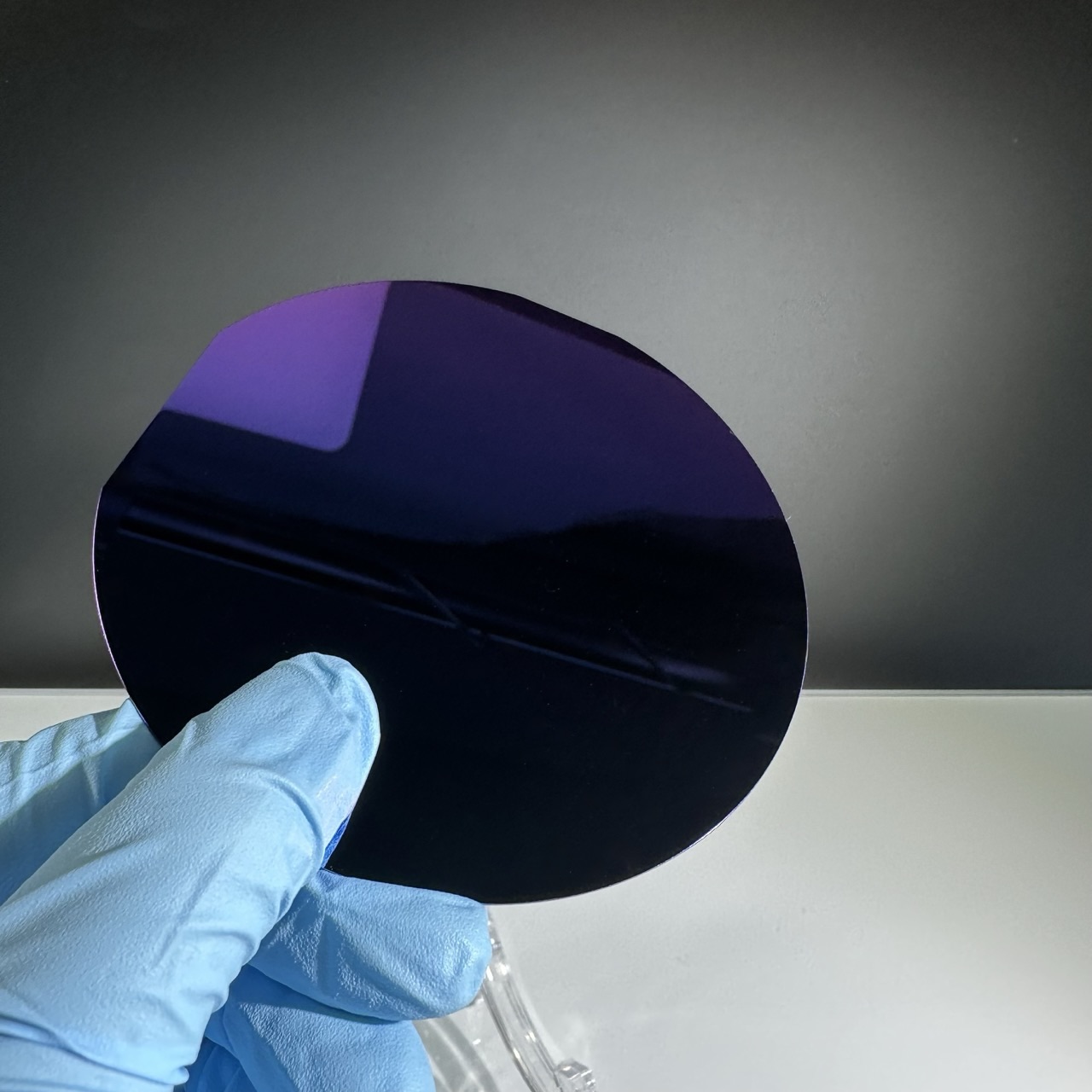

Supported Materials

Optical glass: Quartz, microcrystalline, K9, etc.

Infrared materials: Silicon, germanium, etc.

Metals: Aluminum, stainless steel, titanium alloy, etc.

Crystals: YAG, single-crystal silicon carbide, etc.

Hard/brittle materials: Silicon carbide, etc.

Surface Quality / Precision

PV < 10 nm

RMS ≤ 0.5 nm

Processing Case Studies of Ion Beam Polishing Machine

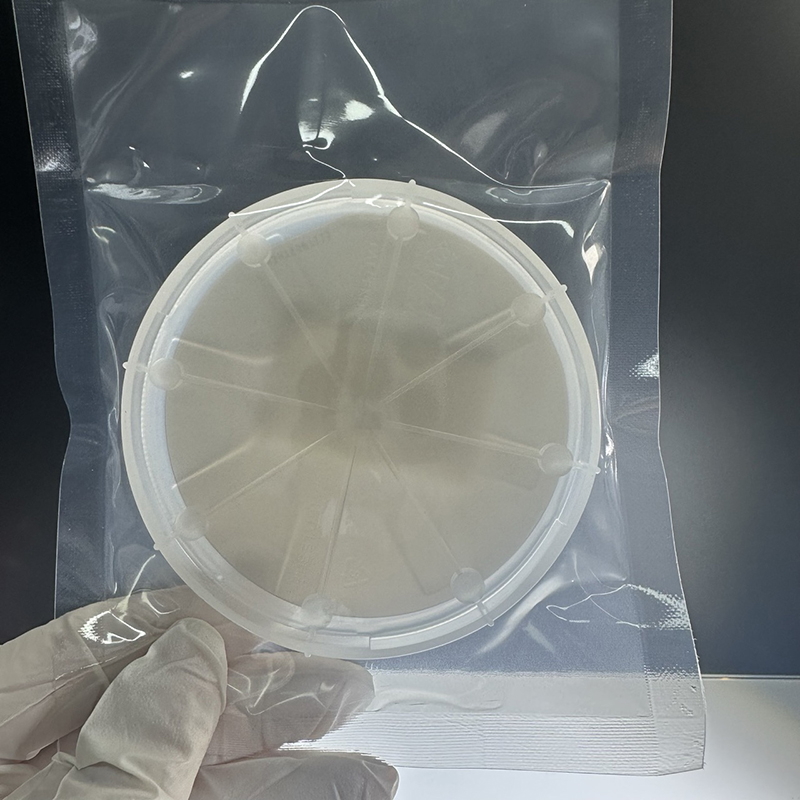

Case 1 – Standard Flat Mirror

Workpiece: D630 mm quartz flat

Result: PV 46.4 nm; RMS 4.63 nm

Case 2 – X-ray Reflective Mirror

Workpiece: 150 × 30 mm silicon flat

Result: PV 8.3 nm; RMS 0.379 nm; Slope 0.13 µrad

Case 3 – Off-Axis Mirror

Workpiece: D326 mm off-axis ground mirror

Result: PV 35.9 nm; RMS 3.9 nm

FAQ of Quartz Glasses

FAQ – Ion Beam Polishing Machine

Q1: What is ion beam polishing?

A1: Ion beam polishing is a non-contact process that uses a focused beam of ions (such as argon ions) to remove material from a workpiece surface. The ions are accelerated and directed toward the surface, causing atomic-level material removal, resulting in ultra-smooth finishes. This process eliminates mechanical stress and subsurface damage, making it ideal for precision optical components.

Q2: What types of surfaces can the Ion Beam Polishing Machine process?

A2: The Ion Beam Polishing Machine can process a variety of surfaces, including simple optical components like flats, spheres, and prisms, as well as complex geometries like aspheres, off-axis aspheres, and freeform surfaces. It is especially effective on materials like optical glass, infrared optics, metals, and hard/brittle materials.

Q3: What materials can the Ion Beam Polishing Machine work with?

A3: The Ion Beam Polishing Machine can polish a wide range of materials, including:

-

Optical glass: Quartz, microcrystalline, K9, etc.

-

Infrared materials: Silicon, germanium, etc.

-

Metals: Aluminum, stainless steel, titanium alloy, etc.

-

Crystal materials: YAG, single-crystal silicon carbide, etc.

-

Other hard/brittle materials: Silicon carbide, etc.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.