UV Laser Marking Machine Plastic Glass PCB Cold Marking Air Cooled 3W/5W/10W Options

Detailed Diagram

Introduction to UV Laser Marking Machine

A UV laser marking machine is a high-precision industrial device that utilizes ultraviolet laser beams, typically at a wavelength of 355nm, to perform non-contact and highly detailed marking, engraving, or surface processing on a wide range of materials. This type of machine operates based on a cold processing technique, which causes minimal thermal influence on the target material, making it ideal for applications that require high contrast and minimal material deformation.

UV laser marking is particularly effective for delicate substrates such as plastics, glass, ceramics, semiconductors, and metals with special coatings. The ultraviolet laser disrupts molecular bonds on the surface rather than melting the material, resulting in smooth, clear, and permanent marks without damaging adjacent areas.

Thanks to its ultra-fine beam quality and excellent focus, the UV laser marker is widely used in industries such as electronics, medical devices, aerospace, cosmetics packaging, and integrated circuit production. It can engrave serial numbers, QR codes, micro-text, logos, and other identifiers with exceptional clarity. The system is also valued for its low maintenance, high reliability, and ability to integrate with automated production lines for continuous operation.

Working Principle of UV Laser Marking Machine

The UV laser marking machine operates based on a photochemical reaction mechanism, primarily relying on the high-energy ultraviolet laser beam to break the molecular bonds on the surface of a material. Unlike conventional infrared lasers that apply thermal energy to ablate or melt the substrate, UV lasers work through a process known as "cold processing." This results in extremely precise material removal or surface modification with negligible heat-affected zones.

The core technology involves a solid-state laser that emits light at a base wavelength (typically 1064nm), which is then passed through a series of nonlinear crystals to generate third-harmonic generation (THG), resulting in a final output wavelength of 355nm. This short wavelength provides superior focusability and higher absorption by a broader range of materials, especially non-metallic ones.

When the focused UV laser beam interacts with the workpiece, the high photon energy directly disrupts molecular structures without significant thermal diffusion. This allows for high-resolution marking on heat-sensitive substrates like PET, polycarbonate, glass, ceramics, and electronic components, where traditional lasers may cause warping or discoloration. Additionally, the laser system is controlled via high-speed galvanometer scanners and CNC software, ensuring micron-level precision and repeatability.

Paramete of UV Laser Marking Machine

| No. | Parameter | Specification |

|---|---|---|

| 1 | Machine Model | UV-3WT |

| 2 | Laser Wavelength | 355nm |

| 3 | Laser Power | 3W / 20KHz |

| 4 | Repetition Rate | 10-200KHz |

| 5 | Marking Range | 100mm × 100mm |

| 6 | Line Width | ≤0.01mm |

| 7 | Marking Depth | ≤0.01mm |

| 8 | Minimum Character | 0.06mm |

| 9 | Marking Speed | ≤7000mm/s |

| 10 | Repeat Accuracy | ±0.02mm |

| 11 | Power Requirement | 220V/Single-phase/50Hz/10A |

| 12 | Total Power | 1KW |

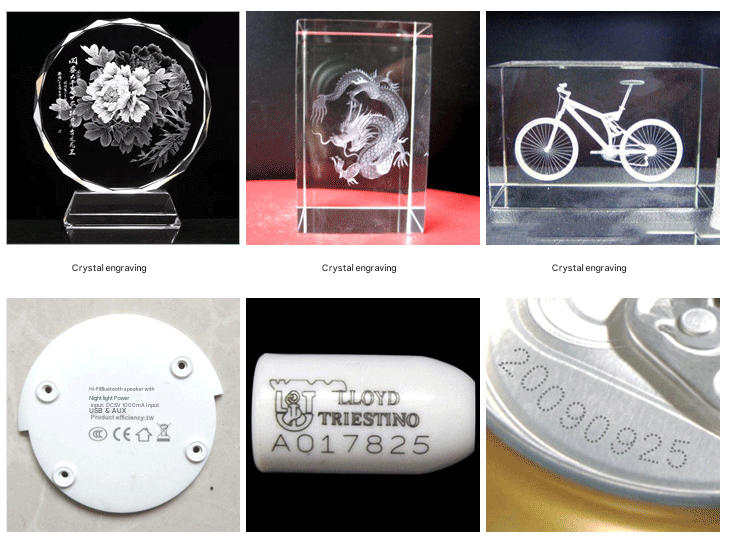

Applications of UV Laser Marking Machines

UV laser marking machines are widely adopted across numerous industries due to their high precision, minimal thermal effect, and compatibility with a broad range of materials. Below are key application areas:

Electronics & Semiconductor Industry: Used for micro-marking IC chips, PCBs, connectors, sensors, and other electronic components. UV lasers can create extremely small and precise characters or codes without damaging delicate circuits or causing conductivity issues.

Medical Devices & Packaging: Ideal for marking syringes, IV bags, plastic tubes, and medical-grade polymers. The cold marking process ensures sterility is maintained and does not compromise the integrity of medical tools.

Glass and Ceramics: UV lasers are highly effective in engraving barcodes, serial numbers, and decorative patterns onto glass bottles, mirrors, ceramic tiles, and quartz substrates, leaving smooth, crack-free edges.

Plastic Components: Perfect for marking logos, batch numbers, or QR codes on ABS, PE, PET, PVC, and other plastics. UV lasers provide high-contrast results without burning or melting the plastic.

Cosmetics & Food Packaging: Applied to transparent or colored plastic containers, caps, and flexible packaging to imprint expiration dates, batch codes, and brand identifiers with high clarity.

Automotive and Aerospace: For durable, high-resolution part identification, especially on sensors, wire insulation, and light covers made from sensitive materials.

Thanks to its superior performance on fine-detail marking and non-metallic substrates, the UV laser marker is essential for any manufacturing process that demands reliability, hygiene, and ultra-precise marking.

Frequently Asked Questions (FAQ) about UV Laser Marking Machines

Q1: What materials are compatible with UV laser marking machines?

A1: UV laser markers are ideal for a wide variety of non-metallic and some metallic materials, including plastics (ABS, PVC, PET), glass, ceramics, silicon wafers, sapphire, and coated metals. They perform exceptionally well on heat-sensitive substrates.

Q2: How does UV laser marking differ from fiber or CO₂ laser marking?

A2: Unlike fiber or CO₂ lasers that rely on thermal energy, UV lasers use a photochemical reaction to mark the surface. This results in finer detail, less thermal damage, and cleaner marks, especially on soft or transparent materials.

Q3: Is UV laser marking permanent?

A3: Yes, UV laser marking creates high-contrast, durable, and wear-resistant markings that are permanent under normal usage conditions, including exposure to water, heat, and chemicals.

Q4: What maintenance is required for UV laser marking systems?

A4: UV lasers require minimal maintenance. Regular cleaning of optical components and air filters, along with proper cooling system checks, ensures stable long-term performance. Lifespan of the UV laser module typically exceeds 20,000 hours.

Q5: Can it be integrated into automated production lines?

A5: Absolutely. Most UV laser marking systems support integration via standard industrial protocols (e.g., RS232, TCP/IP, Modbus), allowing them to be embedded into robotic arms, conveyors, or smart manufacturing systems.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.