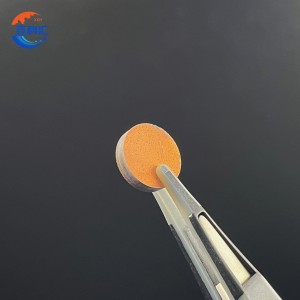

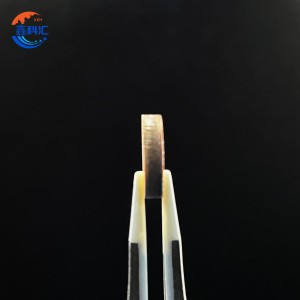

Diamond-Copper Composite Thermal Management Materials

Detailed Diagram

Product Introduction

The Diamond-Copper Composite (Cu-Diamond) is an ultra-high-performance thermal management material that combines the world’s best heat conductor — diamond — with the superior electrical and mechanical properties of copper.

Designed for cutting-edge electronics and power devices, this composite achieves a unique balance of extreme thermal conductivity, controllable thermal expansion, and mechanical stability, enabling reliable operation even under the most demanding thermal environments.

Unlike conventional copper, tungsten, or molybdenum-based substrates, Diamond-Copper composites deliver up to twice the thermal conductivity while significantly reducing weight, making them the preferred choice for semiconductor packaging, laser systems, aerospace electronics, and high-power LED modules.

Material Principle

At the heart of the composite lies diamond particles uniformly embedded within a copper matrix.

Each diamond particle acts as a micro heat sink, spreading heat rapidly, while the copper matrix ensures electrical conduction and structural integrity.

Through advanced manufacturing methods — including vacuum infiltration, chemical coating, and spark plasma sintering (SPS) — a strong and stable interface bond is formed, guaranteeing long-term reliability under continuous thermal cycling.

Technical Highlights

|

|

|

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Applications

-

High-Power Semiconductor Modules (IGBT, MOSFET, RF & microwave packages)

-

Laser Diodes and Optoelectronic Devices

-

Aerospace and Defense Cooling Systems

-

High-Performance LED Heat Spreaders

-

IC and CPU Heat Sinks for Advanced Computing

-

Power Amplifiers and Optical Communication Equipment

Why Choose Diamond-Copper Composite?

Because heat matters.

In the era of miniaturization and high energy density, managing heat effectively defines the lifetime and performance of every device.

The Cu-Diamond composite ensures:

-

Longer device lifespan

-

Enhanced operational stability

-

Improved power efficiency

-

Reduced thermal fatigue

FAQ of Quartz Glasses

Q1: Can Cu-Diamond composites be customized for specific chip materials?

Yes. The diamond volume fraction and CTE can be precisely tuned to match Si, GaN, or SiC-based devices.

Q2: Is metallization required before soldering?

Yes. Surface metallization (Ni/Au, Ti/Ni/Au) is recommended to ensure excellent bonding and minimal thermal resistance.

Q3: How does it perform under high-frequency or pulsed heat conditions?

Diamond’s superior heat spreading ensures rapid temperature equalization, making it ideal for high-frequency and pulse-loaded components.

Q4: What is the maximum operating temperature?

The composite remains stable up to 600°C in inert or vacuum environments, depending on the coating and bonding interface.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.