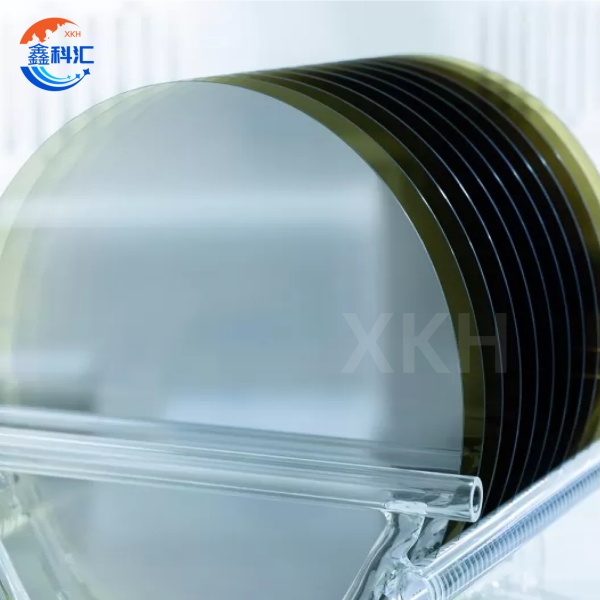

Customized SiC Seed Crystal Substrates Dia 205/203/208 4H-N Type for Optical Communications

Technical parameters

Silicon carbide seed wafer |

|

Polytype |

4H |

Surface orientation error |

4°toward<11-20>±0.5º |

Resistivity |

customization |

Diameter |

205±0.5mm |

Thickness |

600±50μm |

Roughness |

CMP,Ra≤0.2nm |

Micropipe Density |

≤1 ea/cm2 |

Scratches |

≤5,Total Length≤2*Diameter |

Edge chips/indents |

None |

Front laser marking |

None |

Scratches |

≤2,Total Length≤Diameter |

Edge chips/indents |

None |

Polytype areas |

None |

Back laser marking |

1mm (from top edge) |

Edge |

Chamfer |

Packaging |

Multi-wafer cassette |

Key Characteristics

1. Crystal Structure and Electrical Performance

· Crystallographic Stability: 100% 4H-SiC polytype dominance, zero multicrystalline inclusions (e.g., 6H/15R), with XRD rocking curve full-width at half-maximum (FWHM) ≤32.7 arcsec.

· High Carrier Mobility: Electron mobility of 5,400 cm²/V·s (4H-SiC) and hole mobility of 380 cm²/V·s, enabling high-frequency device designs.

·Radiation Hardness: Withstands 1 MeV neutron irradiation with a displacement damage threshold of 1×10¹⁵ n/cm², ideal for aerospace and nuclear applications.

2. Thermal and Mechanical Properties

· Exceptional Thermal Conductivity: 4.9 W/cm·K (4H-SiC), triple that of silicon, supporting operation above 200°C.

· Low Thermal Expansion Coefficient: CTE of 4.0×10⁻⁶/K (25–1000°C), ensuring compatibility with silicon-based packaging and minimizing thermal stress.

3. Defect Control and Processing Precision

· Micropipe Density: <0.3 cm⁻² (8-inch wafers), dislocation density <1,000 cm⁻² (verified via KOH etching).

· Surface Quality: CMP-polished to Ra <0.2 nm, meeting EUV lithography-grade flatness requirements.

Key Applications

|

Domain |

Application Scenarios |

Technical Advantages |

|

Optical Communications |

100G/400G lasers, silicon photonics hybrid modules |

InP seed substrates enable direct bandgap (1.34 eV) and Si-based heteroepitaxy, reducing optical coupling loss. |

|

New Energy Vehicles |

800V high-voltage inverters, onboard chargers (OBC) |

4H-SiC substrates withstand >1,200 V, reducing conduction losses by 50% and system volume by 40%. |

|

5G Communications |

Millimeter-wave RF devices (PA/LNA), base station power amplifiers |

Semi-insulating SiC substrates (resistivity >10⁵ Ω·cm) enable high-frequency (60 GHz+) passive integration. |

|

Industrial Equipment |

High-temperature sensors, current transformers, nuclear reactor monitors |

InSb seed substrates (0.17 eV bandgap) deliver magnetic sensitivity up to 300%@10 T. |

Key Advantages

SiC (silicon carbide) seed crystal substrates deliver unparalleled performance with 4.9 W/cm·K thermal conductivity, 2–4 MV/cm breakdown field strength, and 3.2 eV wide bandgap, enabling high-power, high-frequency, and high-temperature applications. Featuring zero micropipe density and <1,000 cm⁻² dislocation density, these substrates ensure reliability in extreme conditions. Their chemical inertness and CVD-compatible surfaces (Ra <0.2 nm) support advanced heteroepitaxial growth (e.g., SiC-on-Si) for optoelectronics and EV power systems.

XKH Services:

1. Customized Production

· Flexible Wafer Formats: 2–12-inch wafers with circular, rectangular, or custom-shaped cuts (±0.01 mm tolerance).

· Doping Control: Precise nitrogen (N) and aluminum (Al) doping via CVD, achieving resistivity ranges from 10⁻³ to 10⁶ Ω·cm.

2. Advanced Process Technologies

· Heteroepitaxy: SiC-on-Si (compatible with 8-inch silicon lines) and SiC-on-Diamond (thermal conductivity >2,000 W/m·K).

· Defect Mitigation: Hydrogen etching and annealing to reduce micropipe/density defects, improving wafer yield to >95%.

3. Quality Management Systems

· End-to-End Testing: Raman spectroscopy (polytype verification), XRD (crystallinity), and SEM (defect analysis).

· Certifications: Compliant with AEC-Q101 (automotive), JEDEC (JEDEC-033), and MIL-PRF-38534 (military-grade).

4. Global Supply Chain Support

· Production Capacity: Monthly output >10,000 wafers (60% 8-inch), with 48-hour emergency delivery.

· Logistics Network: Coverage in Europe, North America, and Asia-Pacific via air/sea freight with temperature-controlled packaging.

5. Technical Co-Development

· Joint R&D Labs: Collaborate on SiC power module packaging optimization (e.g., DBC substrate integration).

· IP Licensing: Provide GaN-on-SiC RF epitaxial growth technology licensing to reduce client R&D costs.

Summary

SiC (silicon carbide) seed crystal substrates, as a strategic material, are reshaping global industrial chains through breakthroughs in crystal growth, defect control, and heterogeneous integration. By continuously advancing wafer defect reduction, scaling 8-inch production, and expanding heteroepitaxial platforms (e.g., SiC-on-Diamond), XKH deliver high-reliability, cost-effective solutions for optoelectronics, new energy, and advanced manufacturing. Our commitment to innovation ensures clients lead in carbon neutrality and intelligent systems, driving the next era of wide-bandgap semiconductor ecosystems.