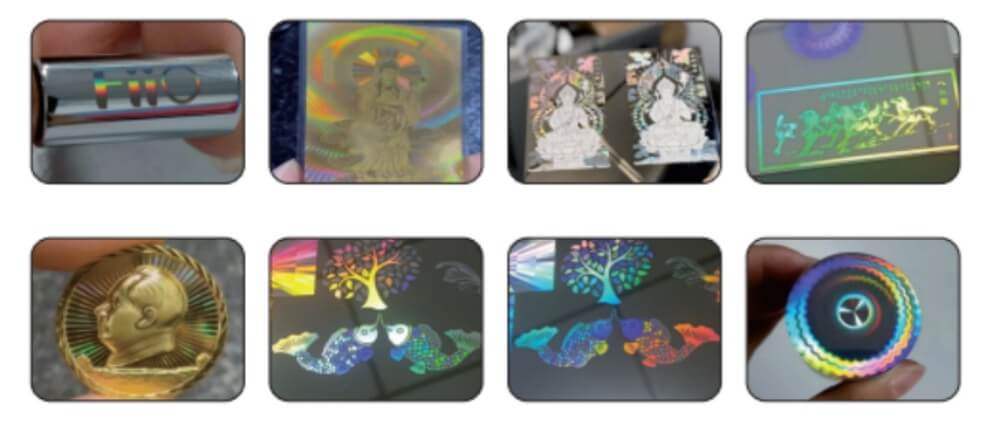

Ultrafast Laser Rainbow Marking Machine Metal Interference Stripes

Key Features

Femtosecond Laser Technology

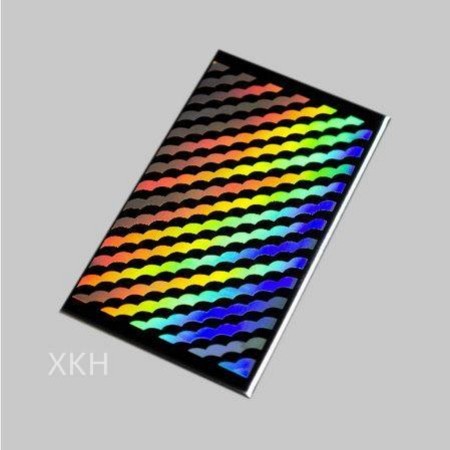

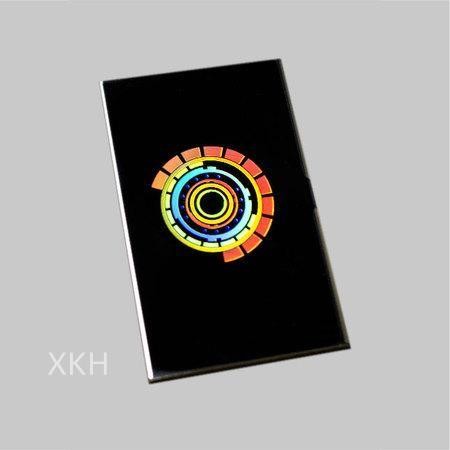

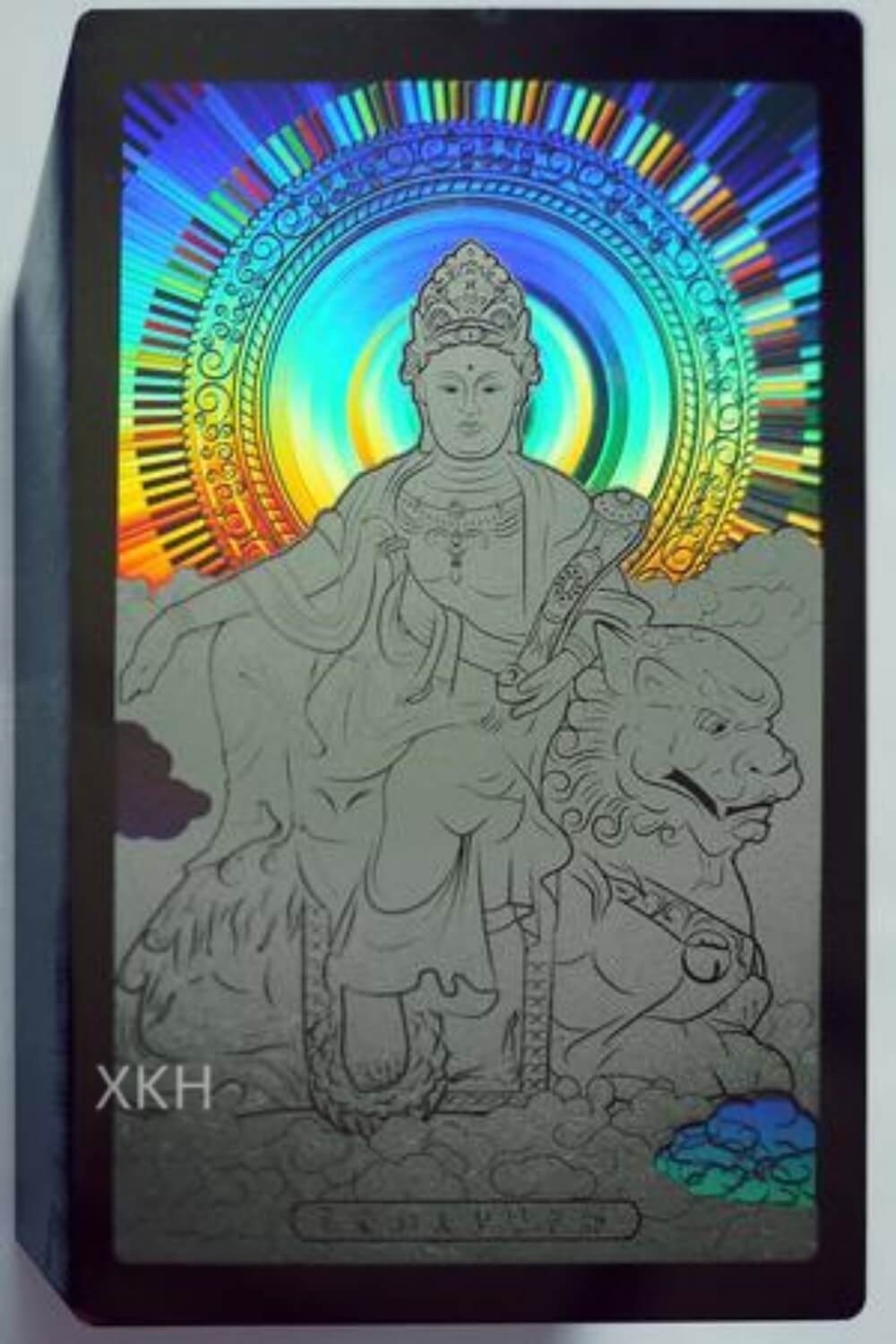

By delivering ultrashort laser bursts with extremely high peak power, the system creates controlled ionization on the target surface. This precise interaction modifies surface topology on a nanoscale, generating optical interference that results in colorful, iridescent patterns.

Advanced Beam Control Software

Equipped with a built-in intelligent software suite, the system offers meticulous control over beam path, repetition rates, and scanning speeds. This enables the creation of complex geometries, customized angles of visibility, and multi-directional color dynamics.

Broad Material Compatibility

Supports direct engraving on metals like stainless steel, nickel, chromium, and PVD coatings. Additionally, through pattern transfer technology, the system enables replication of rainbow effects on polymers, precious metals, flexible films, and more.

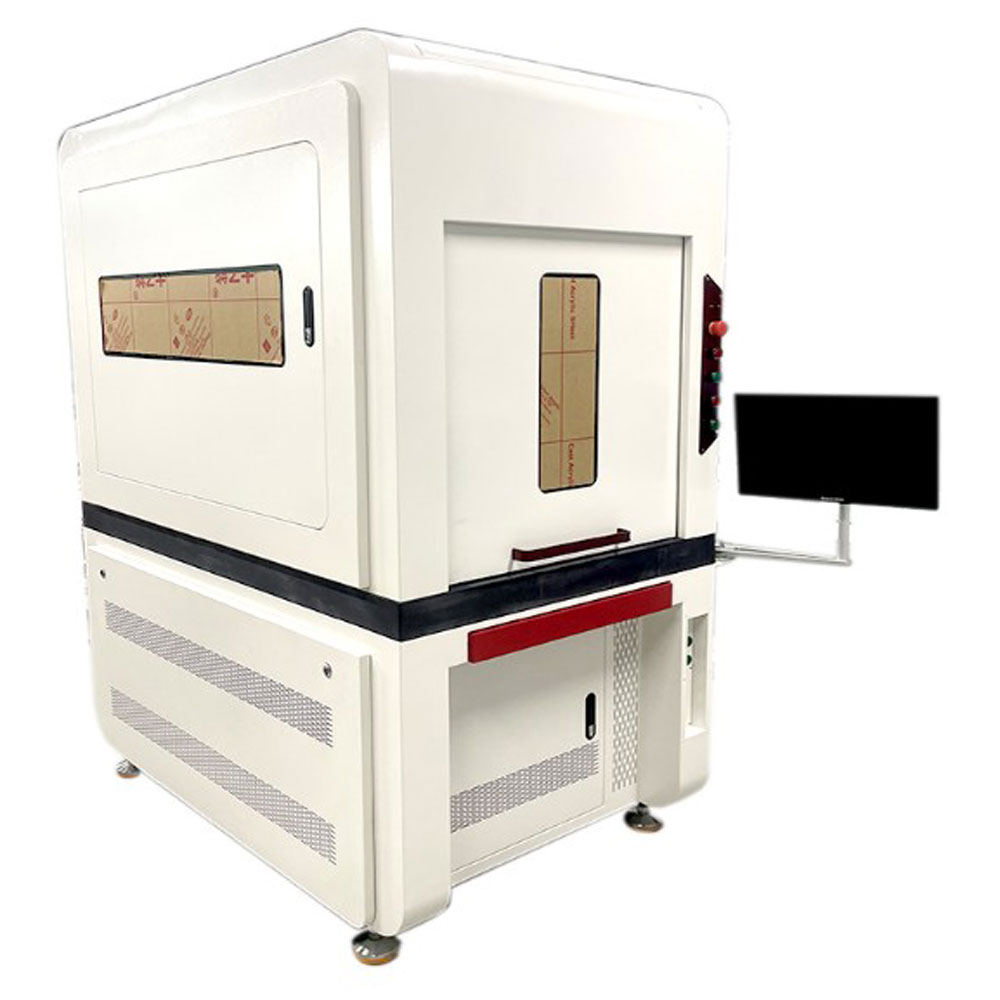

Precision Visual Alignment

A high-resolution CCD vision alignment system ensures precise positioning for every marking cycle. Whether working with miniature parts or high-volume batches, the system guarantees uniformity and pinpoint accuracy.

Industrial-Grade Water Cooling

An integrated closed-loop water cooling unit maintains optimal thermal conditions even during extended operations, ensuring system reliability and longevity.

Technical Specifications

|

Parameter |

Value |

| Average Laser Power | 2500W |

| Wavelength | 1060 nm |

| Repetition Frequency | 1 – 1000 kHz |

| Peak Power Stability | <5% RMS |

| Average Power Stability | <1% RMS |

| Beam Quality (M²) | ≤1.2 |

| Working Area | 150 mm × 150 mm (custom sizes available) |

| Minimum Line Width | 0.01 mm |

| Marking Speed | ≤3000 mm/s |

| Visual Alignment | Integrated CCD Mapping System |

| Cooling Method | Water cooling |

| Operating Temp. Range | 15°C to 35°C |

| Supported File Formats | PLT, DXF, and others |

Application Areas

Brand Security & Authentication

Ideal for anti-counterfeiting applications such as pharmaceutical packaging, cosmetic labels, tobacco seals, and currency-grade holographic embossing. Each pattern's visual complexity makes it resistant to reproduction via traditional printing or copying.

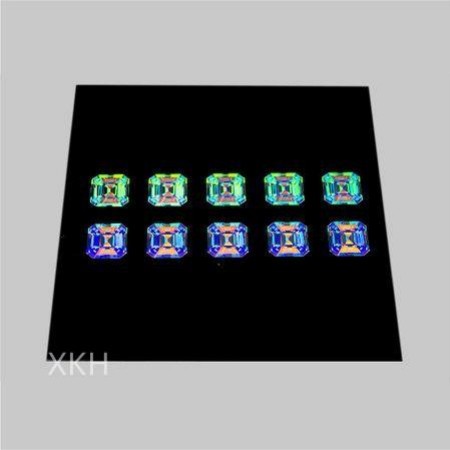

Luxury Product Customization

Creates elegant rainbow aesthetics on high-end product surfaces like stainless steel cosmetics containers, watch components, premium jewelry tags, and collector’s items—enhancing both perceived value and brand identity.

Nanostructure Functionalization

Applicable in functional surface engineering, such as modifying reflection properties of solar panels to increase light absorption efficiency by introducing nano-scale textures.

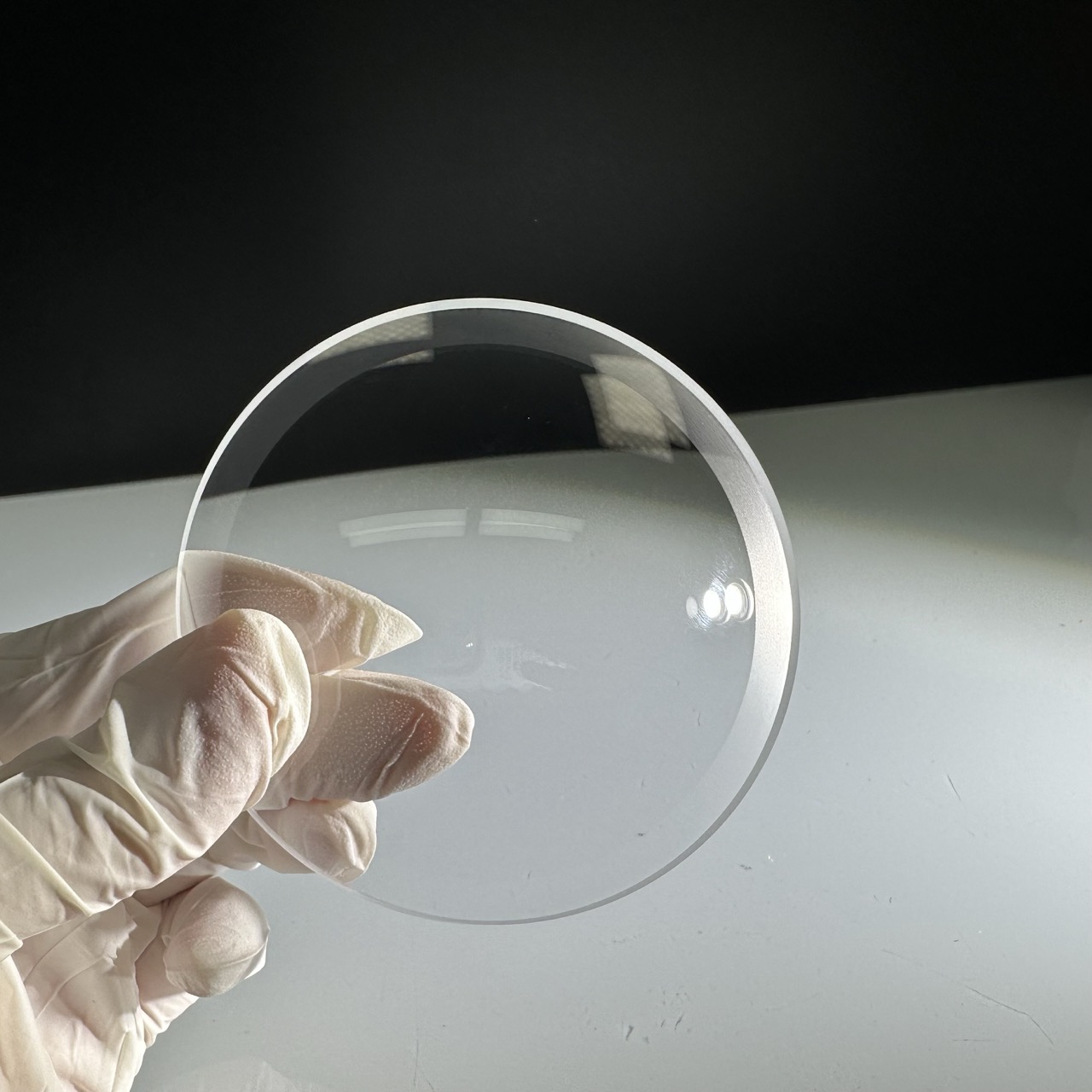

Transfer Patterning

Allows rainbow-structured designs to be transferred from processed molds onto polymers, PET films, metal foils, and luxury packaging substrates—ideal for flexible branding, decorative foils, and tamper-proof seals.

FAQs

Q1: How does the rainbow marking contribute to anti-counterfeiting?

A1: The iridescent effect stems from nano-level interference patterns created through ultrafast laser structuring. These complex, angle-sensitive visuals are nearly impossible to replicate using standard manufacturing or printing methods, ensuring strong protection against forgery.

Q2: What materials are compatible with this system?

A2: The machine can directly process metals such as stainless steel, chromium, nickel, and various PVD-coated surfaces. For other materials such as plastic, film, and soft metals, a mold-based transfer process is used to replicate the rainbow pattern.

Q3: Can the rainbow effect be customized for specific applications?

A3: Yes, designs can be tailored to include angle-specific visuals, micro-features, logos, and concealed symbols that only appear under certain lighting or viewing angles—meeting the needs of brand protection, currency verification, and artistic styling.

Q4: Is this system suitable for industrial-scale production?

A4: Absolutely. With marking speeds up to 3000 mm/s and robust thermal management, the system is designed for high-throughput environments and 24/7 operation on production lines.

Detailed Diagram