Inverted Swing-Type Multi-Wire Diamond Saw machine High-Speed High-Precision

Detailed Diagram

Product Overview

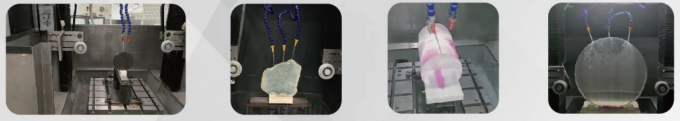

TJ2000 is a high-speed, high-precision multi-wire diamond saw engineered for precision slicing of hard and brittle materials.

The system adopts an inverted structure in which the workpiece swings and feeds downward from top to bottom while the diamond wire remains stationary.

This cutting concept effectively reduces wire vibration and patterning, providing high throughput together with excellent surface quality and dimensional accuracy.

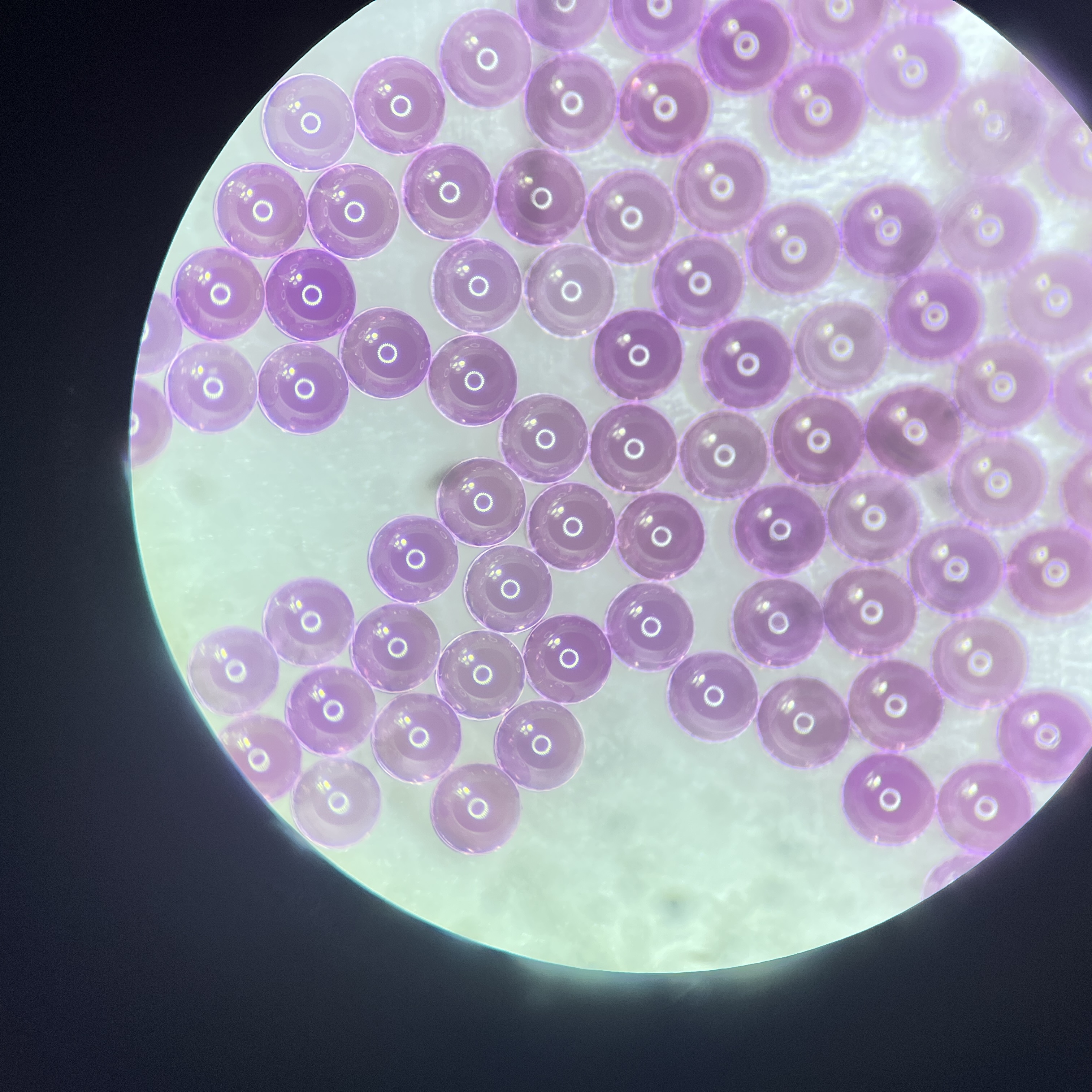

Application Materials & Workpiece Size

The TJ2000 is designed for large-size and ultra-thin cutting of:

Silicon carbide (SiC)

Sapphire

Advanced ceramics

Precious metals

Quartz

Semiconductor materials

Optical glass

Laminated glass

Maximum workpiece size: φ204 × 500 mm.

Cutting thickness range: 0.1 – 20 mm, with typical thickness accuracy around 0.01 mm, covering standard wafers and ultra-thin substrates for:

Crystal ingot slicing

Sapphire substrate production

Ceramic substrate opening

Optical component cutting, etc.

Cutting Method & Motion Control

-

Cutting method: inverted swing cutting (workpiece swings, diamond wire stationary)

Swing range: ±8°

Swing speed: ≈ 0.83°/s

Vertical lifting stroke of worktable: 250 mm

Maximum cutting depth: 500 mm

The continuously changing cutting trajectory significantly suppresses periodic wire marks and interference patterns, improving surface flatness and thickness uniformity.

A full-servo drive architecture ensures precise, repeatable motion on all axes.

Wire System & Cutting Performance

-

Supported diamond wire diameters: 0.1 – 0.5 mm

-

Wire speed: up to 2000 m/min

-

Cutting feed speed: 0.01 – 10 mm/min

-

Cutting tension range: 10 – 60 N, adjustable with 0.1 N minimum step

-

Wire storage capacity: up to 20 km of wire (based on φ0.25 mm)

These features enable:

-

Fine tuning of process parameters for different materials and wire diameters

-

High-efficiency slicing without sacrificing surface quality

-

Long continuous cutting runs with fewer wire changes and higher equipment uptime

Cooling, Filtration & Auxiliary Systems

-

Coolant tank capacity: 300 L

-

Dedicated high-efficiency, anti-rust cutting fluid circulation system

The system provides:

-

Stable cooling and lubrication at the cutting zone

-

Efficient chip removal

-

Reduced edge chipping, micro-cracks, and thermal damage

-

Extended service life of diamond wire and guide rollers

Machine Structure & Power Configuration

-

Power supply: AC 380 V / 50 Hz, three-phase, five-wire

-

Total installed power: ≤ 92 kW

-

Water-cooled main motor, plus multiple independent servo motors for:

-

Wire driving and winding

-

Tension control

-

Worktable swing

-

Worktable lifting, etc.

-

Mechanical structure:

-

Overall dimensions (including rocker arm box): ≈ 2850 × 1320 × 3000 mm

-

Machine weight: ≈ 8000 kg

The high-rigidity frame and heavy-duty design ensure excellent vibration resistance and long-term stability under high-load, long-duration operation.

Ergonomic HMI and optimized maintenance space facilitate loading/unloading of large workpieces and routine service.

Machine Structure & Power Configuration

| No. | Item | Specification |

|---|---|---|

| 1 | Maximum workpiece size | Ø204 × 500 mm |

| 2 | Main roller coating diameter | Ø240 × 510 mm, two main rollers |

| 3 | Wire running speed | 2000 m/min (max.) |

| 4 | Diamond wire diameter | 0.1 – 0.5 mm |

| 5 | Line storage capacity of supply wheel | 20 km (based on Ø0.25 mm diamond wire) |

| 6 | Cutting thickness range | 0.1 – 20 mm |

| 7 | Cutting accuracy | 0.01 mm |

| 8 | Vertical lifting stroke of workstation | 250 mm |

| 9 | Cutting method | Workpiece sways and descends from top to bottom while the diamond wire remains stationary |

| 10 | Cutting feed speed | 0.01 – 10 mm/min |

| 11 | Water tank | 300 L |

| 12 | Cutting fluid | Anti-rust high-efficiency cutting fluid |

| 13 | Swing angle | ±8° |

| 14 | Swing speed | 0.83°/s |

| 15 | Maximum cutting tension | 10 – 60 N, minimum setting unit 0.1 N |

| 16 | Cutting depth (loading capacity) | 500 mm |

| 17 | Workbenches | 1 |

| 18 | Power supply | Three-phase, five-wire AC 380 V / 50 Hz |

| 19 | Total power of machine tool | ≤ 92 kW |

| 20 | Main motor (water circulation cooling) | 22 kW × 2 |

| 21 | Wiring motor | 2 kW × 1 |

| 22 | Workbench swing motor | 1.5 kW × 1 |

| 23 | Workbench rising and falling motor | 0.4 kW × 1 |

| 24 | Tension control motor (water circulation cooling) | 5.5 kW × 2 |

| 25 | Wire release and collection motor | 15 kW × 2 |

| 26 | External dimensions (excluding rocker arm box) | 2660 × 1320 × 2660 mm |

| 27 | External dimensions (including rocker arm box) | 2850 × 1320 × 3000 mm |

| 28 | Machine weight | 8000 kg |

FAQ of Quartz Glasses

Q1. What materials can the TJ2000 cut?

A:

The TJ2000 is designed for precision slicing of hard and brittle materials, including:

-

Silicon carbide (SiC)

-

Sapphire

-

Advanced / technical ceramics

-

Precious metals and hard alloys (depending on hardness and process)

-

Quartz and special glasses

-

Semiconductor crystal materials

-

Optical glass and laminated glass

Q2. What is the maximum workpiece size and cutting thickness range?

A:

-

Maximum workpiece size: Ø204 × 500 mm

-

Cutting thickness range: 0.1 – 20 mm

-

Typical thickness accuracy: ≈ 0.01 mm (depending on material and process conditions)

This covers both standard wafers and ultra-thin substrates.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.