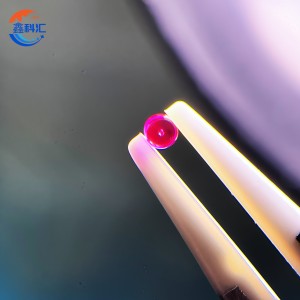

Through-Hole Ruby Bearing sapphire bearings

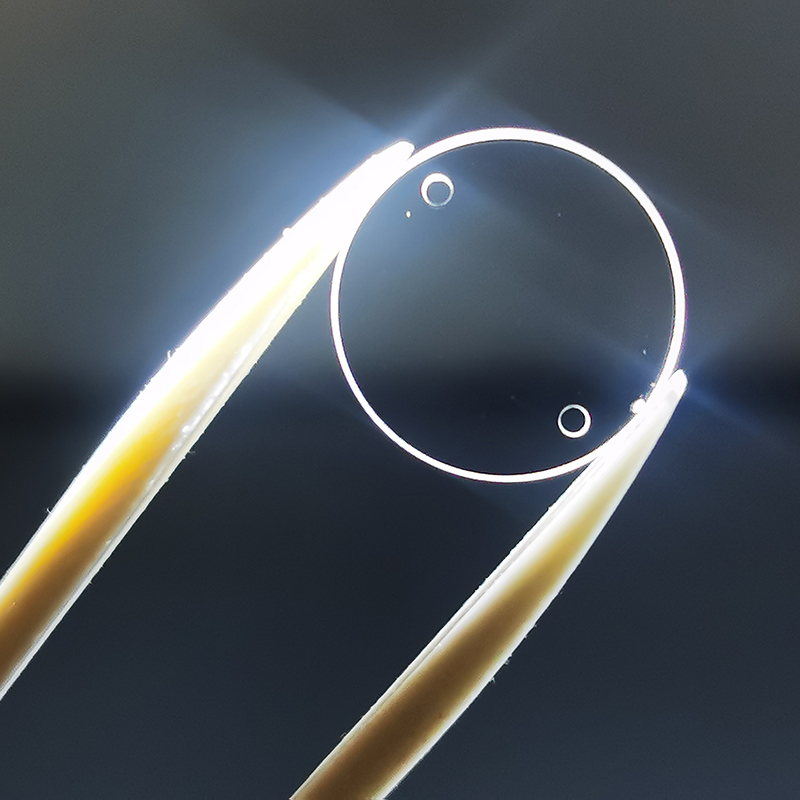

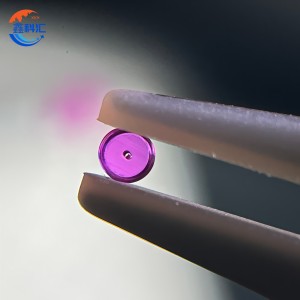

Detailed Diagram

Product Overview

Through-hole ruby bearings are precision-engineered components made from synthetic single-crystal ruby (Al₂O₃ doped with Cr₂O₃). These bearings are designed with a central through-hole structure that allows shafts, pins, or optical fibers to pass through smoothly while minimizing friction and wear. Owing to ruby’s extreme hardness (Mohs 9), outstanding chemical stability, and excellent surface finish, these bearings are widely used in precision instruments, metering devices, fiber optic assemblies, and micro-mechanical systems where stability and long lifespan are critical.

Material and Structure

The bearing body is made of synthetic corundum crystal, grown under controlled conditions to ensure uniform hardness and purity. Chromium doping gives the material its characteristic red color and adds optical clarity and corrosion resistance. The through-hole is precisely machined and polished to achieve micron-level dimensional accuracy and smoothness, ensuring excellent coaxiality and low friction in rotary or oscillating movement.

Typical Parameters

| Parameter | Value |

|---|---|

| Material | Synthetic Ruby (Al₂O₃ + trace Cr₂O₃) |

| Hardness | 9 on Mohs scale |

| Density | 3.98 g/cm³ |

| Working Temperature | -60°C to 500°C |

| Bore Diameter | 0.05–5.0 mm (custom available) |

| Outer Diameter | 0.5–10 mm |

| Roundness Tolerance | ≤ 0.0025 mm |

| Surface Finish | Ra ≤ 0.02 μm |

Technical Features

Extreme Hardness and Stability – The ruby crystal resists deformation, abrasion, and chemical attack even in severe operating environments.

Precision Through-Hole Design – Each bore is finished with optical-grade polishing for ultra-smooth motion and minimal friction.

Corrosion and Wear Resistance – Ruby bearings maintain performance in moisture, solvents, and acids without degradation.

Excellent Geometric Accuracy – Tightly controlled manufacturing ensures perfect coaxial alignment and roundness for smooth rotation.

Long-Term Reliability – Operates for years without lubrication or dimensional drift, ideal for continuous or repetitive motion applications.

Applications

Through-hole ruby bearings are frequently utilized in:

-

Precision Measuring Instruments: Micrometers, gauges, and metrology tools that require consistent motion accuracy.

-

Optical and Laser Systems: Acting as guiding and positioning elements for optical fibers, lenses, and laser alignment devices.

-

Watches and Miniature Motors: Offering wear-free pivot points for small rotating shafts and axles.

-

Medical Devices: Applied in fluid pumps, diagnostic systems, and flow control units where mechanical precision is vital.

-

Aerospace and Navigation Equipment: Ensuring stability and accuracy in compact and vibration-resistant mechanisms.

FAQ

Q1: What makes through-hole ruby bearings suitable for precision instruments?

A: Their hardness, roundness, and ultra-smooth bore reduce vibration and friction, which is critical for accurate and stable movement in precision measuring equipment.

Q2: Can they be used in vacuum or cleanroom conditions?

A: Yes. Ruby bearings are completely free of volatile materials and function perfectly without lubrication, making them ideal for vacuum or semiconductor environments.

Q3: Are there limitations on shaft material or surface finish?

A: For optimal performance, shafts made of polished stainless steel, tungsten carbide, or sapphire are recommended to minimize friction and wear.

Q4: Can I request a non-standard bore size or outer geometry?

A: Yes. We support fully customized ruby bearings according to drawings, including asymmetric bores, countersinks, and flange designs.

Q5: How does ruby compare with sapphire for bearing applications?

A: Both share similar crystal structures and hardness, but ruby’s chromium doping improves visibility and wear tracking, making it slightly preferable for mechanical observation and optical inspection.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.