Synthetic Colored Gemstone White Sapphire gem for jewelry Free-Size Cutting

Key Characteristics

1.Optical Properties

White Sapphire gem exhibits exceptional optical characteristics:

· Maintains superior transmittance across an ultra-broad spectral range (200-5500nm), with >90% transmittance in the visible spectrum (380-780nm) and >85% in UV range (200-380nm)

· Features high refractive index (1.76-1.77 @589nm) and dispersion value (0.018), producing more intense fire than common synthetic spinel

· Demonstrates complete fluorescence inertness under both long-wave (365nm) and short-wave (254nm) UV radiation

· Extremely low birefringence (0.008) ensures ghosting-free imaging, making it ideal for precision optical components

2.Physical Properties

White Sapphire gem possesses outstanding physical parameters:

· Mohs hardness 9 (second only to diamond), Vickers hardness 2200-2300kg/mm² (10× harder than standard glass)

· Density 3.98g/cm³, identical to natural sapphire with premium tactile quality

· Anisotropic thermal expansion: 5.3×10⁻⁶/K (parallel to c-axis), 4.8×10⁻⁶/K (perpendicular to c-axis)

· Melting point up to 2053℃, thermal conductivity 35W/(m·K), stable long-term operation at 800℃

· Exceptional chemical inertness (resistant to all acids except HF), suitable for harsh environments

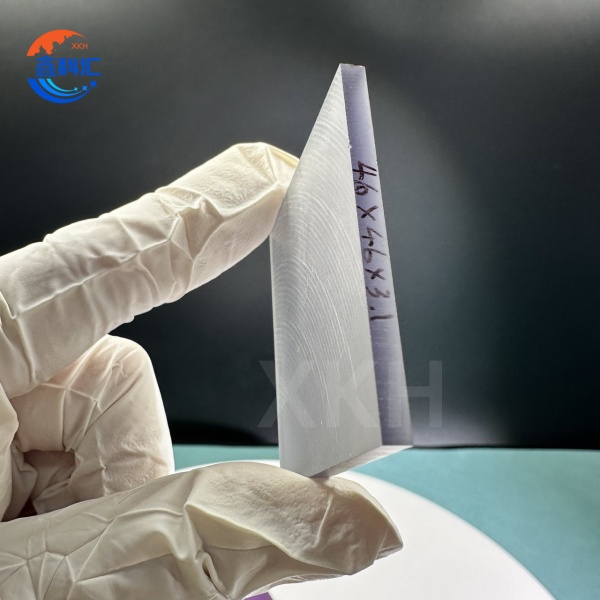

3.Machining Characteristics

White Sapphire gem offers superior processability:

· Ultra-thin cutting capability (0.1mm thickness with ±0.005mm tolerance) for miniaturized devices

· Supports multi-angle faceting (minimum edge angle 30°) for complex cut designs

· Polishable to optical-grade surface finish (Ra<1nm), achieving λ/10 flatness @633nm

· Laser engraving capability (50μm precision) for anti-counterfeit markings without affecting transmittance

· Special forming processes enable curved surfaces with minimum 5mm bending radius

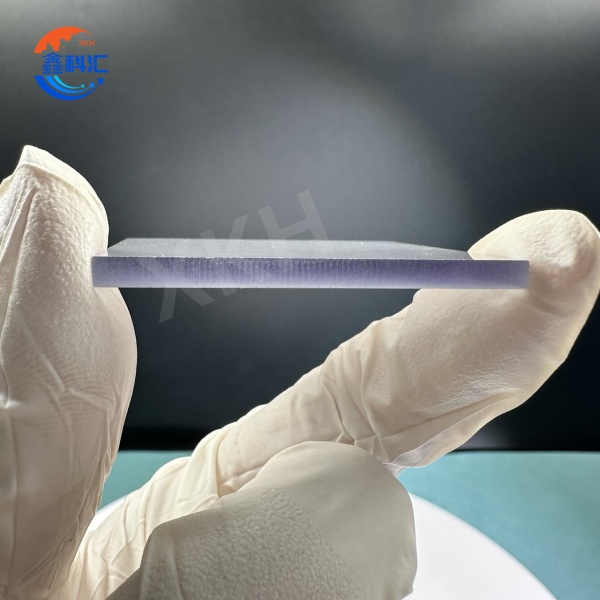

4.Quality Assurance

White Sapphire gem adheres to stringent quality standards:

· Internally flawless (IF clarity grade) with no visible inclusions

· 100% manual inspection ensures absence of growth striations or bubbles

· Batch-wise XRD testing guarantees crystal structure integrity

· Comprehensive test reports document all critical performance parameters

Primary Applications

1.High-End Jewelry Design

White Sapphire gem has extensive jewelry applications:

· Premium diamond alternative available in all popular cuts (round, princess, emerald, pear)

· Ideal for classic eternity rings, pendants and earrings, perfectly complementing platinum/18K white gold settings

· Large-size rough materials (up to 100mm diameter) enable statement jewelry pieces

· Fluorescence-free property makes it preferred for museum-grade collections

· Adopted by luxury brands like Tiffany and Cartier for ethical luxury collections

2.Luxury Watchmaking

White Sapphire gem revolutionizes horology:

· Superior scratch resistance as watch crystals (comparable to sapphire glass)

· Customizable into complex case geometries for high-end timepieces

· Laser-engraved logos/security marks with 50μm precision

· Thermal expansion compatibility with metals ensures long-term stability

· Used by Richard Mille and Hublot for fully transparent cases

3.Optical Instruments

White Sapphire gem excels in optical applications:

· High-end camera lens protection without image degradation

· Laser system output windows withstand high-power irradiation

· Spectrometer prisms and beam splitters ensure measurement accuracy

· Microscope stages and objectives provide clear observation surfaces

· Astronomical telescope corrector lenses minimize aberrations

4.Industrial Applications

White Sapphire gem meets demanding industrial requirements:

· Semiconductor equipment viewports resistant to plasma erosion

· High-vacuum system sealing windows (<1×10⁻¹⁰Pa·m³/s leak rate)

· Deep-sea observation ports withstand 6000m water pressure

· High-temperature endoscopes operational at 1500℃

· Chemical process viewports resist strong acid/alkali corrosion

5.Emerging Technologies

White Sapphire gem enables cutting-edge innovations:

· Quantum communication optical windows

· AR/VR display protective covers

· Biosensor transparent substrates

· Spacecraft viewport materials

· Ultrafast laser optical components

XKH Services

XKH offer comprehensive customization services for White Sapphire gem, providing precision-engineered wafers ranging from 2mm to 100mm in diameter with thickness customization from 0.1mm to 30mm, including specialized crystal orientation cutting (C-axis, A-axis, R-plane, etc.). Our advanced CAD/CAM conversion and precision cutting capabilities enable complex faceting designs (emerald, princess, pear, etc.) with micron-level accuracy (±5μm). Surface treatments include optical-grade polishing (λ/10@633nm), anti-reflective coatings (single-side reflectivity <0.5%), and oleophobic treatments (contact angle >110°). Each White Sapphire gem is accompanied by a detailed inspection report, covering refractive index, density, hardness, and other critical parameters, backed by a 10-year quality guarantee. We also provide R&D support, including new material development, tailored application solutions, and rapid prototyping (3-5 business days). With full-process control from raw material purification to finished product manufacturing, we ensure the highest standards for every White Sapphire gem, driving innovation in high-end jewelry and precision instruments while continuously developing larger and higher-performance variants to meet industry demands.