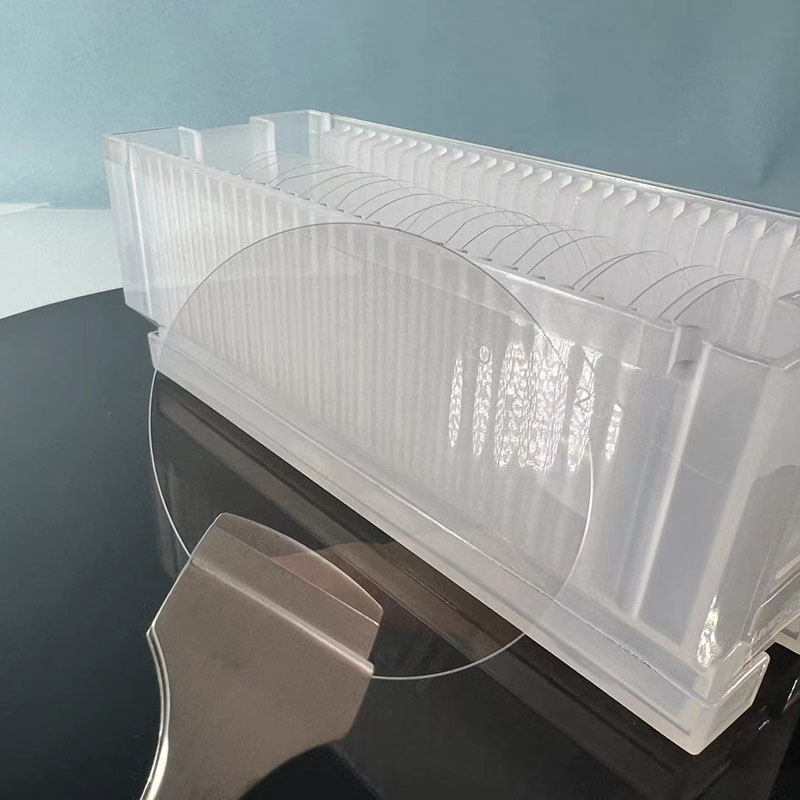

SiC ceramic plate/tray for 4inch 6inch wafer holder for ICP

SiC ceramic plate Abstract

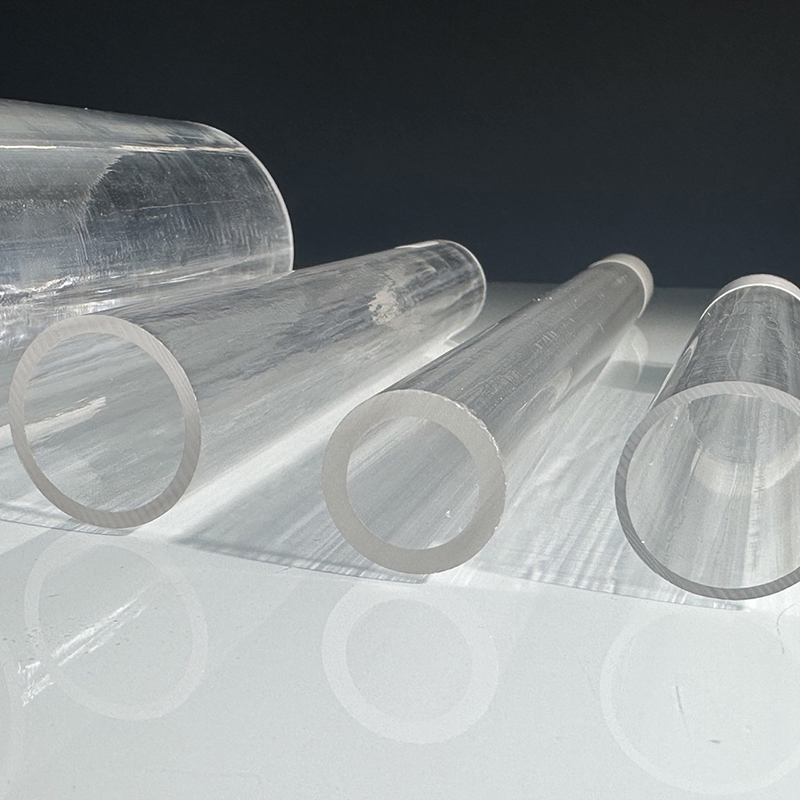

The SiC ceramic plate is a high-performance component engineered from high-purity Silicon Carbide, designed for use in extreme thermal, chemical, and mechanical environments. Renowned for its exceptional hardness, thermal conductivity, and corrosion resistance, the SiC plate is widely used as a wafer carrier, susceptor, or structural component in semiconductor, LED, photovoltaic, and aerospace industries.

With outstanding thermal stability up to 1600°C and excellent resistance to reactive gases and plasma environments, the SiC plate ensures consistent performance during high-temperature etching, deposition, and diffusion processes. Its dense, non-porous microstructure minimizes particle generation, making it ideal for ultra-clean applications in vacuum or cleanroom settings.

SiC ceramic plate Application

1. Semiconductor Manufacturing

SiC ceramic plates are commonly used as wafer carriers, susceptors, and pedestal plates in semiconductor fabrication equipment such as CVD (Chemical Vapor Deposition), PVD (Physical Vapor Deposition), and etching systems. Their excellent thermal conductivity and low thermal expansion allow them to maintain uniform temperature distribution, which is critical for high-precision wafer processing. SiC’s resistance to corrosive gases and plasmas ensures durability in harsh environments, helping reduce particle contamination and equipment maintenance.

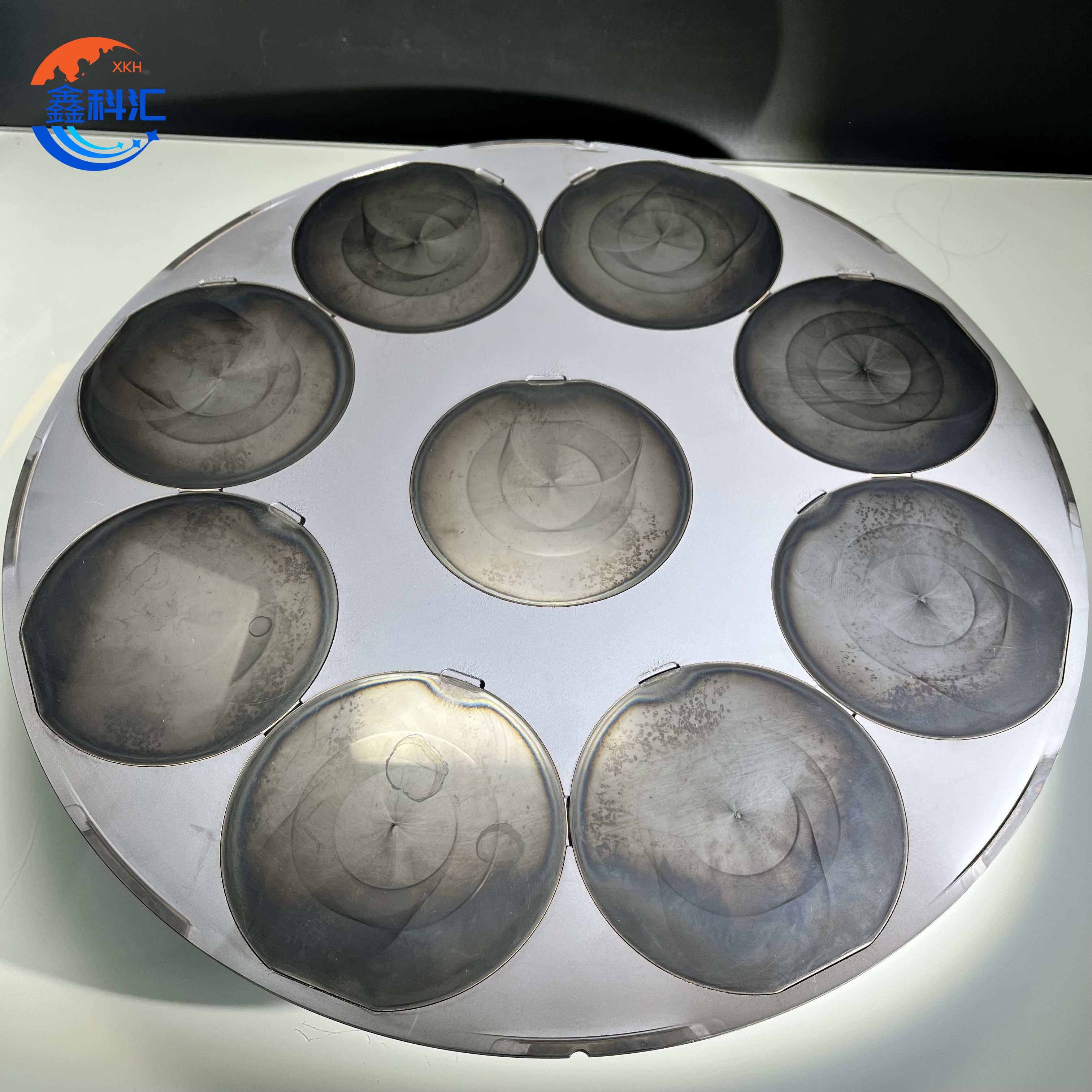

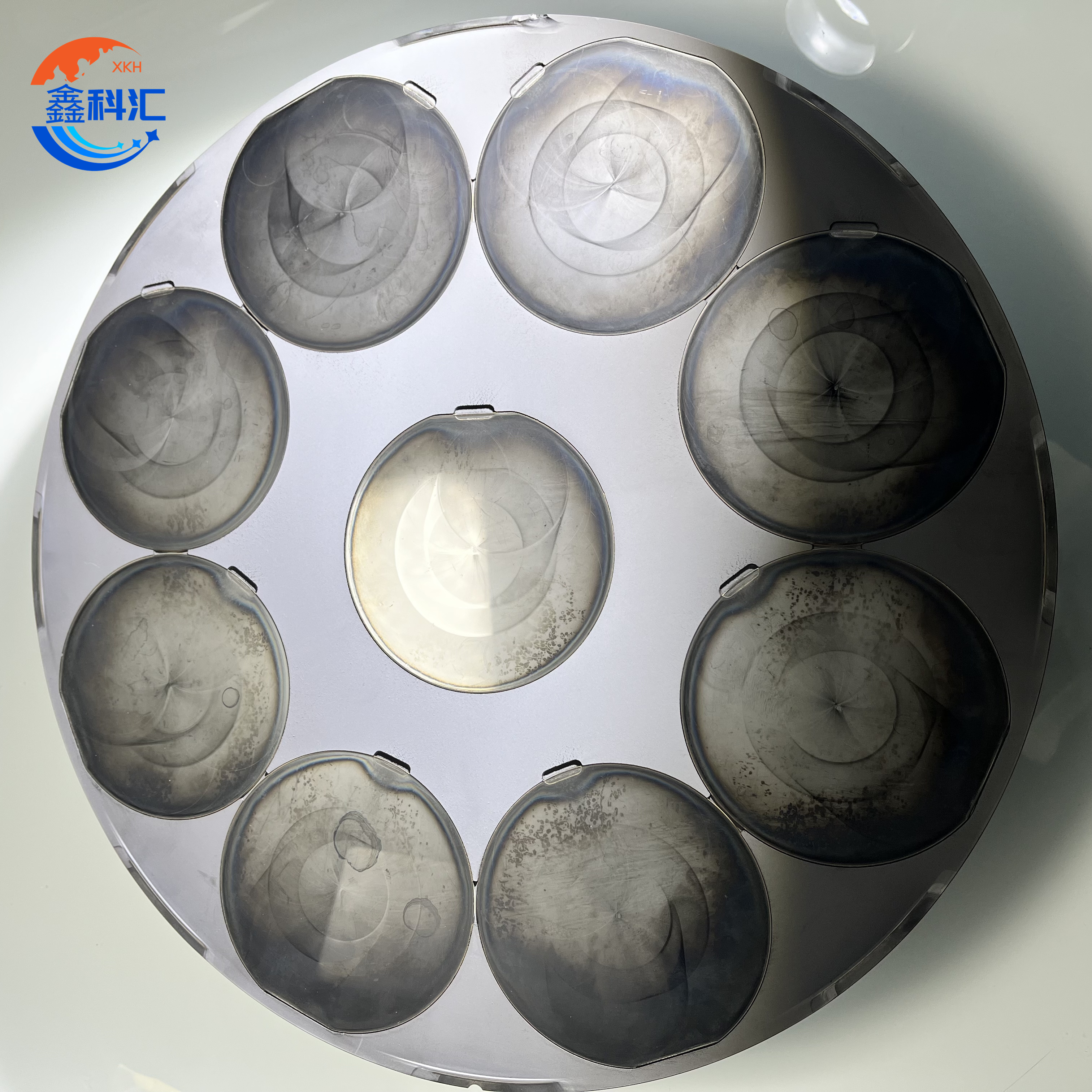

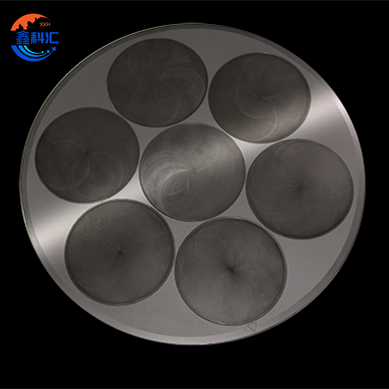

2. LED Industry – ICP Etching

In the LED manufacturing sector, SiC plates are key components in ICP (Inductively Coupled Plasma) etching systems. Acting as wafer holders, they provide a stable and thermally robust platform to support sapphire or GaN wafers during plasma processing. Their excellent plasma resistance, surface flatness, and dimensional stability help ensure high etching accuracy and uniformity, leading to increased yield and device performance in LED chips.

3. Photovoltaics (PV) and Solar Energy

SiC ceramic plates are also used in solar cell production, particularly during high-temperature sintering and annealing steps. Their inertness at elevated temperatures and ability to resist warping ensure consistent processing of silicon wafers. Additionally, their low contamination risk is vital for maintaining the efficiency of photovoltaic cells.

SiC ceramic plate Properties

1. Exceptional Mechanical Strength and Hardness

SiC ceramic plates exhibit very high mechanical strength, with a typical flexural strength exceeding 400 MPa and Vickers hardness reaching >2000 HV. This makes them highly resistant to mechanical wear, abrasion, and deformation, ensuring long service life even under high load or repeated thermal cycling.

2. High Thermal Conductivity

SiC has excellent thermal conductivity (typically 120–200 W/m·K), allowing it to evenly distribute heat across its surface. This property is critical in processes such as wafer etching, deposition, or sintering, where temperature uniformity directly affects product yield and quality.

3. Superior Thermal Stability

With a high melting point (2700°C) and low coefficient of thermal expansion (4.0 × 10⁻⁶/K), SiC ceramic plates maintain dimensional accuracy and structural integrity under rapid heating and cooling cycles. This makes them ideal for applications in high-temperature furnaces, vacuum chambers, and plasma environments.

|

Technical Properties |

||||

|

Index |

Unit |

Value |

||

|

Material Name |

Reaction Sintered Silicon Carbide |

Pressureless Sintered Silicon Carbide |

Recrystallized Silicon Carbide |

|

|

Composition |

RBSiC |

SSiC |

R-SiC |

|

|

Bulk Density |

g/cm3 |

3 |

3.15 ± 0.03 |

2.60-2.70 |

|

Flexural Strength |

MPa (kpsi) |

338(49) |

380(55) |

80-90 (20°C) 90-100(1400°C) |

|

Compressive Strength |

MPa (kpsi) |

1120(158) |

3970(560) |

> 600 |

|

Hardness |

Knoop |

2700 |

2800 |

/ |

|

Breaking Tenacity |

MPa m1/2 |

4.5 |

4 |

/ |

|

Thermal Conductivity |

W/m.k |

95 |

120 |

23 |

|

Coefficient of Thermal Expansion |

10-6.1/°C |

5 |

4 |

4.7 |

|

Specific Heat |

Joule/g 0k |

0.8 |

0.67 |

/ |

|

Max temperature in air |

℃ |

1200 |

1500 |

1600 |

|

Elastic Modulus |

Gpa |

360 |

410 |

240 |

SiC ceramic plate Q&A

Q:What are the properties of silicon carbide plate?

A: Silicon carbide (SiC) plates are known for their high strength, hardness, and thermal stability. They offer excellent thermal conductivity and low thermal expansion, ensuring reliable performance under extreme temperatures. SiC is also chemically inert, resistant to acids, alkalis, and plasma environments, making it ideal for semiconductor and LED processing. Its dense, smooth surface minimizes particle generation, maintaining cleanroom compatibility. SiC plates are widely used as wafer carriers, susceptors, and support components in high-temperature and corrosive environments across the semiconductor, photovoltaic, and aerospace industries.