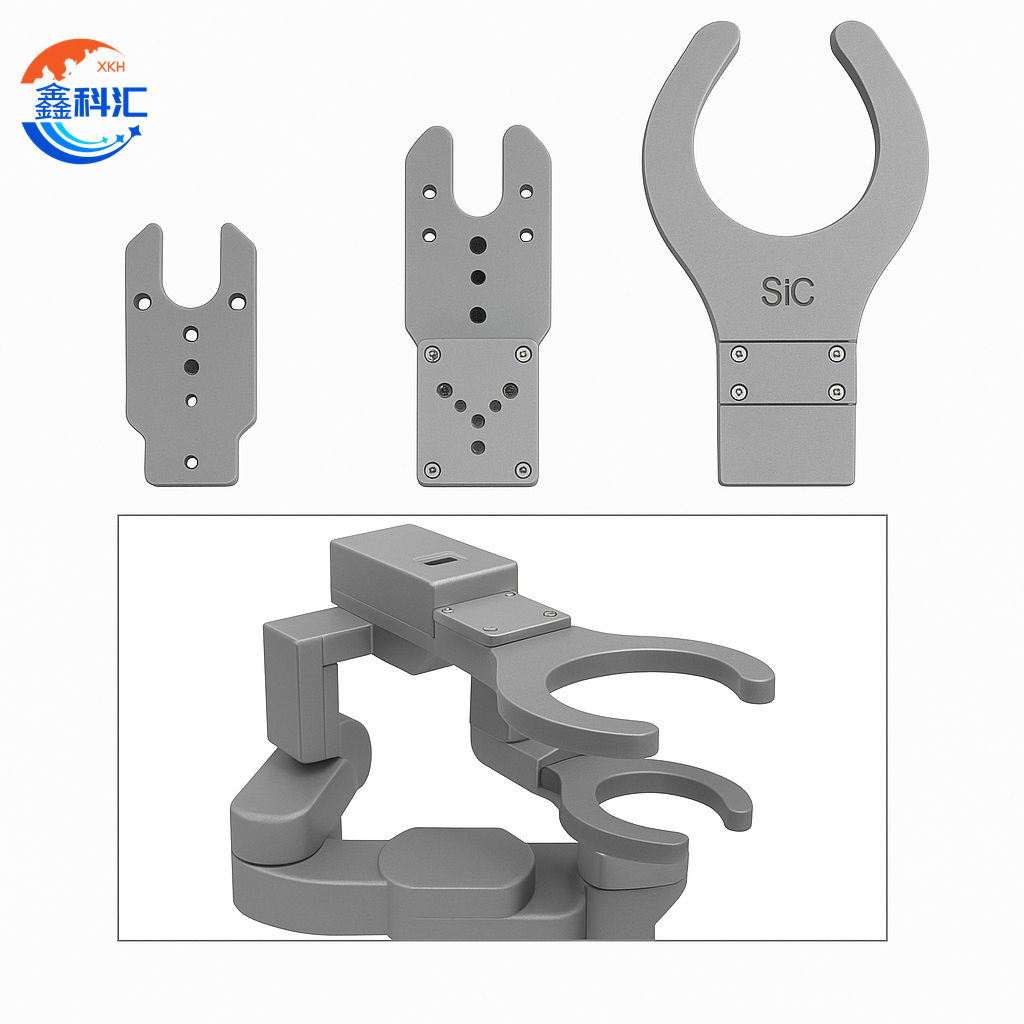

SiC ceramic end effector handing arm for wafer carring

SiC ceramic end effector Abstract

The SiC (Silicon Carbide) ceramic end-effector is a critical component in high-precision wafer handling systems used in semiconductor manufacturing and advanced microfabrication environments. Engineered to meet the demanding requirements of ultra-clean, high-temperature, and highly stable environments, this specialized end-effector ensures reliable and contamination-free transportation of wafers during key production steps such as lithography, etching, and deposition.

Leveraging the superior material properties of silicon carbide—such as high thermal conductivity, extreme hardness, excellent chemical inertness, and minimal thermal expansion—the SiC ceramic end-effector offers unmatched mechanical stiffness and dimensional stability even under rapid thermal cycling or in corrosive process chambers. Its low particle generation and plasma resistance characteristics make it particularly suited for cleanroom and vacuum processing applications, where maintaining wafer surface integrity and reducing particle contamination are paramount.

SiC ceramic end effector Application

1. Semiconductor Wafer Handling

SiC ceramic end effectors are widely used in the semiconductor industry for handling silicon wafers during automated production. These end effectors are typically mounted on robotic arms or vacuum transfer systems and are designed to accommodate wafers of various sizes such as 200mm and 300mm. They are essential in processes including Chemical Vapor Deposition (CVD), Physical Vapor Deposition (PVD), etching, and diffusion—where high temperatures, vacuum conditions, and corrosive gases are common. SiC’s exceptional thermal resistance and chemical stability make it an ideal material to withstand such harsh environments without degradation.

2. Cleanroom and Vacuum Compatibility

In cleanroom and vacuum settings, where particle contamination must be minimized, SiC ceramics offer significant advantages. The material’s dense, smooth surface resists particle generation, helping maintain wafer integrity during transport. This makes SiC end effectors particularly well-suited for critical processes such as Extreme Ultraviolet Lithography (EUV) and Atomic Layer Deposition (ALD), where cleanliness is crucial. Furthermore, SiC’s low outgassing and high plasma resistance ensure reliable performance in vacuum chambers, extending the lifespan of tools and reducing maintenance frequency.

3. High-Precision Positioning Systems

Precision and stability are vital in advanced wafer handling systems, especially in metrology, inspection, and alignment equipment. SiC ceramics have an extremely low coefficient of thermal expansion and high stiffness, which allow the end effector to maintain its structural accuracy even under thermal cycling or mechanical load. This ensures that wafers remain precisely aligned during transport, minimizing the risk of micro-scratches, misalignment, or measurement errors—factors that are increasingly critical at sub-5nm process nodes.

SiC ceramic end effector Properties

1. High Mechanical Strength and Hardness

SiC ceramics possess exceptional mechanical strength, with a flexural strength often exceeding 400 MPa and Vickers hardness values above 2000 HV. This makes them highly resistant to mechanical stress, impact, and wear, even after prolonged operational use. The high rigidity of SiC also minimizes deflection during high-speed wafer transfers, ensuring accurate and repeatable positioning.

2. Excellent Thermal Stability

One of the most valuable properties of SiC ceramics is their ability to withstand extremely high temperatures—often up to 1600°C in inert atmospheres—without losing mechanical integrity. Their low coefficient of thermal expansion (~4.0 x 10⁻⁶ /K) ensures dimensional stability under thermal cycling, making them ideal for applications such as CVD, PVD, and high-temperature annealing.

SiC ceramic end effector Q&A

Q:What material is used in wafer end effector?

A:Wafer end effectors are commonly made from materials that offer high strength, thermal stability, and low particle generation. Among these, Silicon Carbide (SiC) ceramic is one of the most advanced and preferred materials. SiC ceramics are extremely hard, thermally stable, chemically inert, and resistant to wear, making them ideal for handling delicate silicon wafers in cleanroom and vacuum environments. Compared to quartz or coated metals, SiC offers superior dimensional stability under high temperatures and does not shed particles, which helps prevent contamination.