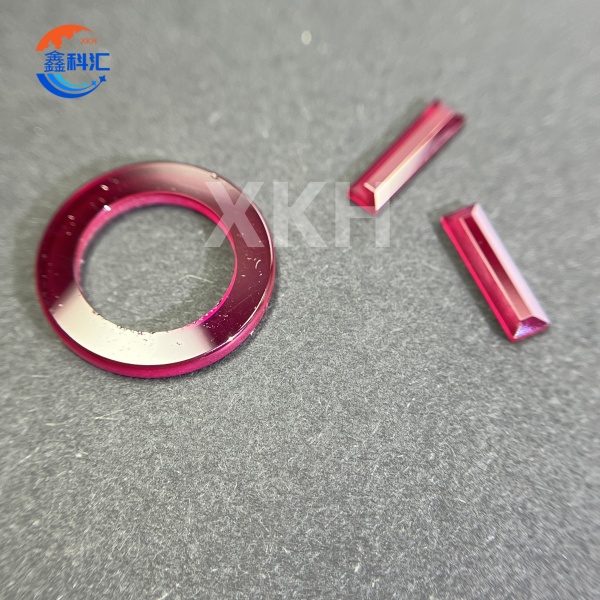

Ruby Optical Components Precision Windows Bearing Assemblies High-Temperature Resistance

Sapphire (α-Al₂O₃) has emerged as a critical functional material in modern industry, demonstrating irreplaceable value across numerous high-tech applications due to its unique physicochemical properties. As a leading provider of sapphire material solutions, XKH possess full industrial chain capabilities—from crystal growth to precision machining—enabling us to deliver customized sapphire components including optical windows, mechanical bearings, and laser elements. Leveraging advanced manufacturing technologies and rigorous quality control systems, we are committed to providing industry clients with high-performance, reliable sapphire product solutions.

Technical specification:

|

Parameter Category |

Specification |

|

Basic Properties |

|

|

Crystal Structure |

Hexagonal (α-Al₂O₃) |

|

Mohs Hardness |

9 |

|

Density |

3.98 g/cm³ |

|

Melting Point |

2050°C |

|

Optical Properties |

|

|

Transmission Range |

0.15-5.5 μm |

|

Refractive Index |

1.76 @ 589nm |

|

Birefringence |

0.008 |

|

Mechanical Properties |

|

|

Flexural Strength |

400-700 MPa |

|

Elastic Modulus |

345 GPa |

|

Thermal Expansion Coeff. |

7.5×10⁻⁶/K (25-1000°C) |

|

Surface Treatment |

|

|

Standard Finish |

Ra ≤ 0.05 μm |

|

High Precision Finish |

Ra ≤ 0.01 μm |

|

Coating Options |

AR/HR/Metallic coatings |

Key Features:

- Exceptional Environmental Adaptability

Sapphire components exhibit outstanding performance in extreme environments, maintaining stable functionality across an extensive temperature range of -200°C to +1000°C. Their unique crystal structure imparts superior thermal shock resistance, preventing cracking or deformation even under rapid temperature fluctuations. In vacuum conditions, sapphire components operate reliably at ultra-high vacuum levels (10⁻⁶ Pa) without outgassing contamination. Additionally, sapphire demonstrates excellent radiation resistance, maintaining structural integrity and functionality at radiation doses up to 10⁶ Gy.

- Unparalleled Durability

With a Mohs hardness of 9 (second only to diamond), sapphire components offer exceptional wear resistance. Comparative testing shows sapphire parts exhibit wear rates just 1/10th of traditional steel components. Chemically, sapphire is resistant to nearly all strong acids (excluding HF), alkalis, and organic solvents. These properties enable sapphire components to achieve service lives 5-8 times longer than conventional materials, significantly reducing maintenance costs and downtime.

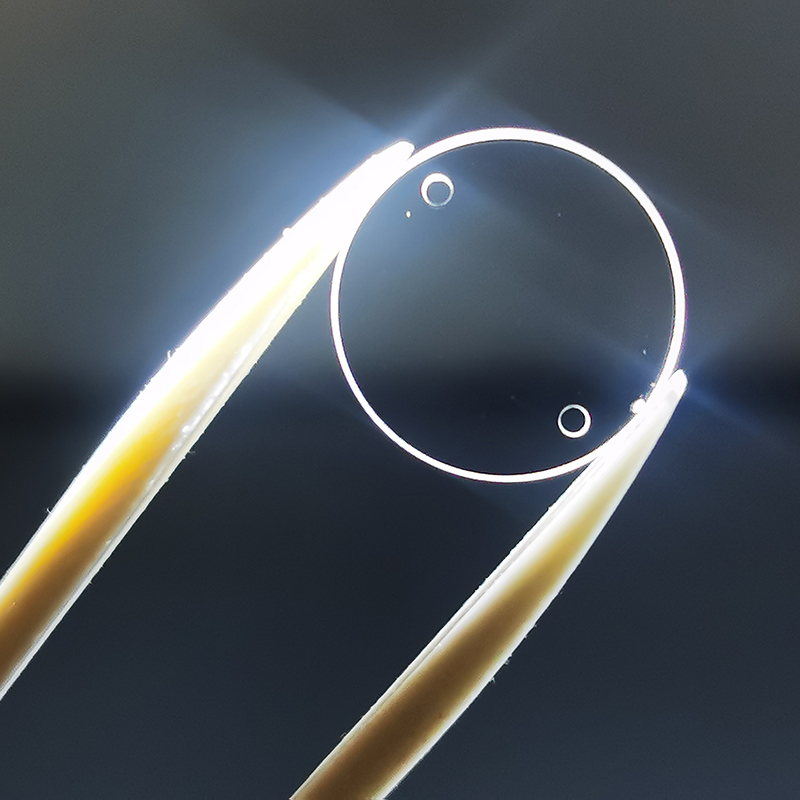

- Superior Precision Performance

Sapphire components provide unique advantages in precision manufacturing. Their ultra-low thermal expansion coefficient (7.5×10⁻⁶/K) ensures dimensional stability, typically achieving ±0.1μm/100mm variation. Through precision machining, we achieve surface flatness of λ/10@632.8nm and angular tolerances of ±15 arc-seconds, meeting the most stringent optical system requirements. These characteristics make sapphire ideal for high-precision measurement and optical applications.

Key Advantages:

- Performance-to-Cost Ratio

Our sapphire components maintain over 85% of key performance metrics while offering more than 30% cost savings compared to traditional sapphire products. Through optimized crystal growth and machining processes, we achieve the optimal balance between performance and cost. Rigorous quality control ensures batch-to-batch consistency with ≤3% parameter deviation.

- Comprehensive Service Capabilities

We maintain a rapid response system, delivering technical solutions within 48 hours. Our flexible production model accommodates orders ranging from 1 to 10,000 units. A 36-step inspection protocol covers dimensional accuracy, surface quality, and mechanical properties to guarantee premium quality standards.

Primary Applications:

High-End Industrial Applications

Semiconductor Manufacturing: Guide rails for wafer handling robots

Precision Metrology: Probes for CMMs (Coordinate Measuring Machines)

Fiber Optics: Drawing nozzles with superior thermal stability

2. Advanced Optical Systems

Laser Technology: High-LIDT (Laser-Induced Damage Threshold) windows and Q-switches

Defense Applications: Infrared missile domes

Spectroscopy: Prisms and windows for analytical instruments

3. Extreme Environment Applications

Aerospace: Attitude control bearings for spacecraft

Deep-Sea Exploration: Pressure-resistant viewports

Nuclear Industry: Radiation-shielded viewing windows

XKH’s Services:

XKH offer end-to-end sapphire component solutions:

· Product Portfolio: 200+ standard models in stock; custom sizes from 0.5-300mm

· Technical Services: Application engineering, FEA simulation, failure analysis

· Surface Treatments: DLC coatings, AR (Anti-Reflective) coatings

· Quality Assurance: Third-party certified inspection reports

· Logistics: 48-hour technical proposals; 2-4 week sample delivery

Conclusion

Sapphire components deliver exceptional value in high-end industrial applications through their unmatched physicochemical properties. This report has detailed their critical characteristics, advantages, and multidisciplinary applications. By combining robust service systems with stringent quality control, XKH provide reliable, cost-effective sapphire solutions. Moving forward, we will continue advancing material performance and processing technologies to expand sapphire’s applications in semiconductors, optics, aerospace, and beyond. We welcome collaborations with industry partners to jointly drive innovation in sapphire material technology.