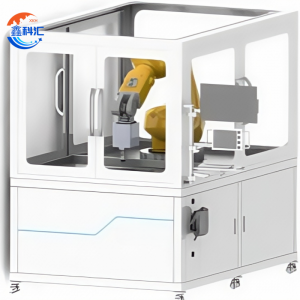

Robotic Polishing Machine – High-Precision Automated Surface Finishing

Detailed Diagram

Overview of Robotic Polishing Machine

The Robotic Polishing Machine is an advanced, fully automated surface processing system designed to meet the highest requirements in precision manufacturing. It combines six-axis robotic control, force-feedback polishing technology, and dual-head configuration to handle a wide range of materials and complex geometries with exceptional accuracy and consistency.

Whether for optical lenses, aerospace parts, precision engineering components, or semiconductor applications, this machine delivers stable, repeatable, and high-quality surface finishes—even at nanometer-level tolerances.

Comprehensive Workpiece Compatibility of Robotic Polishing Machine

The system supports processing of:

-

Flat surfaces for glass, ceramics, and metal plates

-

Cylindrical and conical shapes such as rollers, shafts, and tubes

-

Spherical and aspherical components for optical systems

-

Freeform and off-axis surfaces with complex curves and transitions

Its versatility makes it suitable for both mass production and high-precision custom manufacturing.

Core Features & Benefits of Robotic Polishing Machine

1. Dual Polishing Head Technology

-

Equipped with single-rotation and self-rotation polishing heads for flexibility.

-

Rapid tool change capability supports multiple processing modes without long downtime.

-

Ideal for switching between coarse and fine polishing stages.

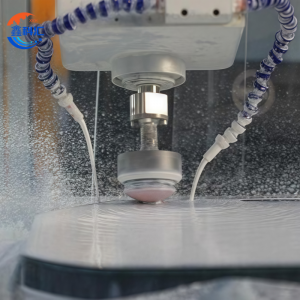

2. Precision Force-Control System

-

Real-time monitoring of pressure, temperature, and polishing fluid flow.

-

Consistent force application ensures uniform surface finish across the workpiece.

-

Capable of adapting to surface irregularities automatically.

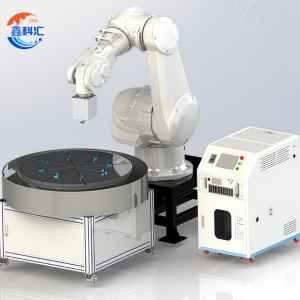

3. Six-Axis Robotic Control

-

Full freedom of movement to handle complex geometries.

-

Smooth, accurate motion paths calculated via advanced algorithms.

-

High repeat positioning accuracy from ±0.04 mm to ±0.1 mm depending on model.

4. Smart Automation & Measurement

-

Auto-calibration tools for precise setup and alignment.

-

Coordinate measurement system for accurate positioning.

-

Optional online thickness monitoring for real-time quality control.

5. Industrial-Grade Build Quality

-

Dual servo-motor design increases polishing efficiency and stability.

-

Rigid mechanical structure minimizes vibration and ensures long-term durability.

Technical Specifications of Robotic Polishing Machine

| Equipment Model | Robot Body | Repeat Positioning Accuracy | Processing Diameter Range | Single Rotation Polishing Head | Multi-Rotation Polishing Head | Small Tool | Main Wheel Type Polishing | Spherical Head Polishing | End Quick Change | Auto Calibration Tool | Coordinate Measurement Head | Online Thickness Monitoring | Numerical Control Platform |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IRP500S | Staubli TX2-90L | ±0.04mm / full range | Φ50~Φ500mm | √ | × | √ | √ | √ | × | ○ | ○ | ○ | ○ |

| IRP600S | Staubli TX2-140 | ±0.05mm / full range | Φ50~Φ600mm | √ | × | √ | √ | √ | × | ○ | ○ | ○ | ○ |

| IRP800S | Staubli TX2-160 | ±0.05mm / full range | Φ80~Φ800mm | √ | √ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP1000S | Staubli TX200/L | ±0.06mm / full range | Φ100~Φ1000mm | √ | ○ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP1000A | ABB IRB6700-200/2.6 | ±0.1mm / full range | Φ100~Φ1000mm | √ | ○ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP2000A | ABB IRB6700-150/3.2 | ±0.1mm / full range | Φ200~Φ2000mm | √ | ○ | √ | √ | √ | × | × | × | ○ | ○ |

| IRP2000AD | ABB IRB6700-150/3.2 | ±0.1mm / full range | Φ200~Φ2000mm | √ | ○ | √ | √ | √ | × | × | × | ○ | ○ |

FAQ – Robot Polishing Machine

1. What types of workpieces can the robot polishing machine handle?

Our robot polishing machine supports various shapes and surfaces, including flat, curved, spherical, freeform, and complex contours. It is suitable for optical components, precision molds, metal surfaces, and other high-precision polishing applications.

2. What is the difference between Single Rotation and Multi-Rotation polishing heads?

-

Single Rotation Polishing Head: The tool rotates around a single axis, ideal for standard surface finishing and high-speed material removal.

-

Multi-Rotation Polishing Head: The tool combines rotation with self-rotation (orbiting), enabling more uniform polishing on curved and irregular surfaces.

3. What is the maximum processing diameter?

Depending on the model:

-

Compact models (e.g., IRP500S) handle Φ50–Φ500mm.

-

Large-scale models (e.g., IRP2000AD) handle up to Φ2000mm.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.