Precision Microjet Laser System for Hard & Brittle Materials

Key Features

Rigid Cross-Slide Structure

The cross-slide type base with symmetric thickened structure minimizes thermal deformation and ensures long-term accuracy. This layout provides excellent rigidity and allows for stable grinding performance under continuous load.

Independent Hydraulic System for Reciprocating Motion

The table's left-right reciprocating movement is powered by an independent hydraulic station with an electromagnetic valve reversing system. This results in smooth, low-noise motion with low heat generation, making it suitable for long-term production.

Anti-Mist Honeycomb Baffle Design

On the left side of the worktable, a honeycomb-style water shield effectively reduces mist generated during wet grinding, enhancing visibility and cleanliness inside the machine.

Dual V-Guide Rails with Servo Ball Screw Feed

The front and rear table movement utilizes long-span dual V-shaped guide rails with a servo motor and ball screw drive. This configuration enables automatic feeding, high positional accuracy, and extended equipment lifespan.

Vertical Feed with High Rigidity Guide

The vertical motion of the grinding head adopts square steel guideways and servo-driven ball screws. This ensures high stability, rigidity, and minimal backlash, even during deep cuts or finish passes.

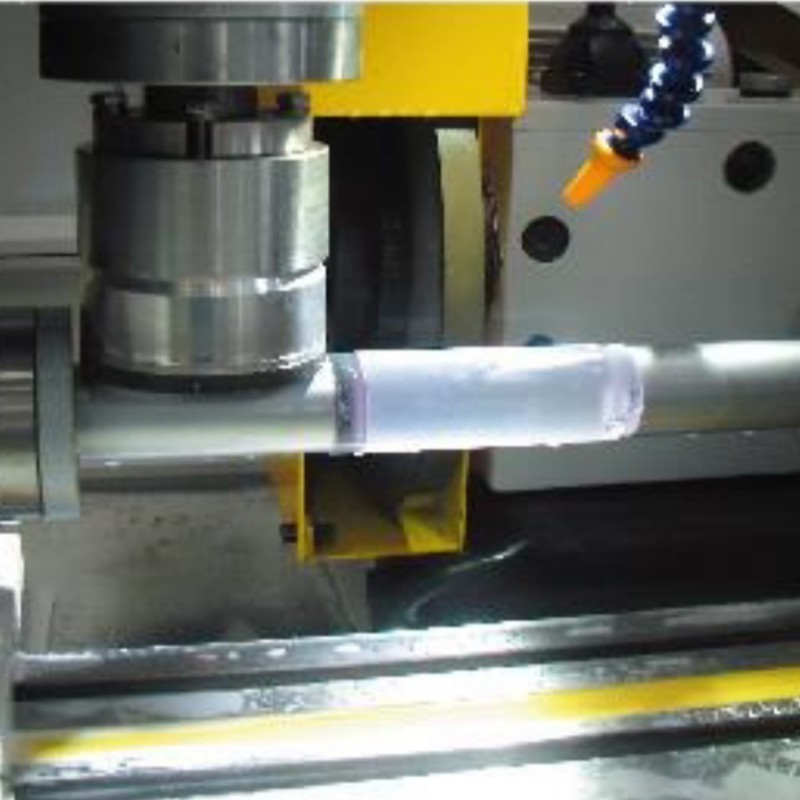

High-Precision Spindle Assembly

Equipped with a high-rigidity and high-precision bearing spindle, the grinding head delivers superior cutting efficiency. The consistent rotational performance ensures excellent surface finish and prolongs spindle life.

Advanced Electrical System

Utilizing Mitsubishi PLCs, servo motors, and servo drives, the electrical control system is designed for reliability and flexibility. An external electronic handwheel offers manual fine-tuning and simplifies setup processes.

Sealed and Ergonomic Design

The full-enclosure design not only improves operational safety but also keeps the internal environment clean. Aesthetic exterior casing with optimized dimensions makes the machine easy to maintain and relocate.

Application Areas

Sapphire Wafer Grinding

Essential for LED and semiconductor industries, this machine ensures the flatness and edge integrity of sapphire substrates, which are vital for epitaxial growth and lithography.

Optical Glass and Window Substrates

Ideal for processing laser windows, high-durability display glass, and protective camera lenses, delivering high clarity and structural integrity.

Ceramic and Advanced Materials

Applicable to alumina, silicon nitride, and aluminum nitride substrates. The machine can handle delicate materials while maintaining tight tolerances.

Research and Development

Preferred by research institutes for experimental material preparation due to its precise control and reliable performance.

Advantages Compared to Traditional Grinding Machines

● Superior accuracy with servo-driven axes and rigid construction

● Faster material removal rates without compromising surface finish

● Lower noise and thermal footprint thanks to hydraulic and servo systems

● Better visibility and cleaner operation due to anti-mist barriers

● Enhanced user interface and easier maintenance procedures

Maintenance & Support

Routine maintenance is simplified with an accessible layout and user-friendly control system. The spindle and guide systems are designed for durability, requiring minimal intervention. Our technical support team offers training, spare parts, and online diagnostics to ensure peak operation throughout the machine's life.

Specification

|

Model |

LQ015 |

LQ018 |

| Max Workpiece Size | 12 inch | 8 inch |

| Max Workpiece Length | 275 mm | 250 mm |

| Table Speed | 3–25 m/min | 5–25 m/min |

| Grinding Wheel Size | φ350xφ127mm (20–40mm) | φ205xφ31.75mm (6–20mm) |

| Spindle Speed | 1440 rpm | 2850 rpm |

| Flatness | ±0.01 mm | ±0.01 mm |

| Parallelism | ±0.01 mm | ±0.01 mm |

| Total Power | 9 kW | 3 kW |

| Machine Weight | 3.5 t | 1.5 t |

| Dimensions (L x W x H) | 2450x1750x2150 mm | 2080x1400x1775 mm |

Conclusion

Whether for mass production or research, the Sapphire CNC Surface Grinding Machine delivers the precision and reliability required for modern material processing. Its intelligent design and robust components make it a long-term asset for any high-tech manufacturing operation.

Detailed Diagram