Microjet Water-Guided Laser Cutting System for Advanced Materials

Top Advantages

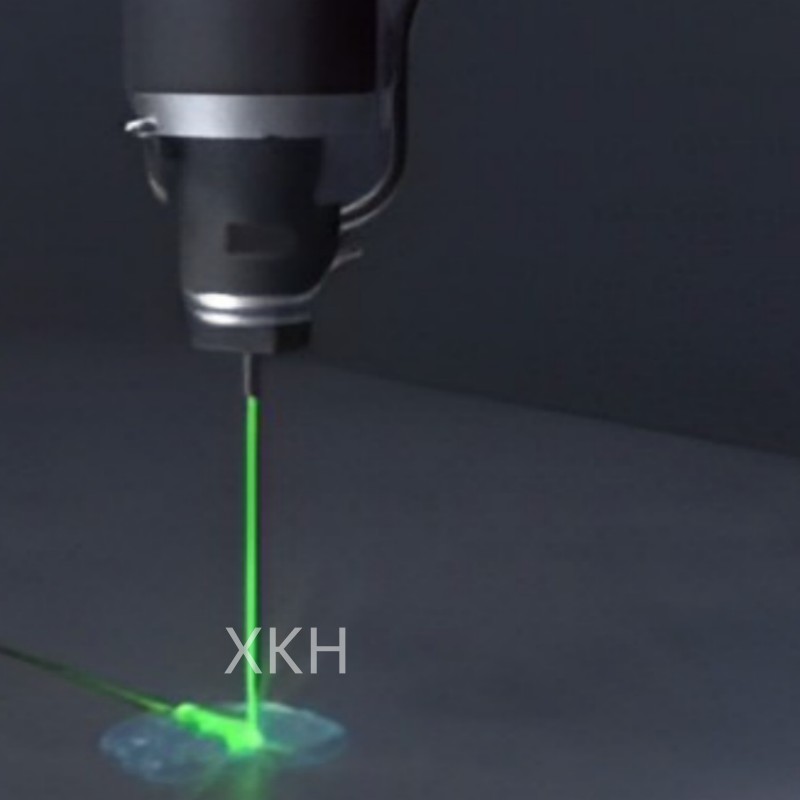

1. Unparalleled Energy Focus through Water Guidance

By using a finely pressurized water jet as a laser waveguide, the system eliminates air interference and ensures full laser focus. The result is ultra-narrow cut widths—as small as 20μm—with sharp, clean edges.

2. Minimal Thermal Footprint

The system’s real-time thermal regulation ensures the heat-affected zone never exceeds 5μm, crucial for preserving material performance and avoiding microcracks.

3. Wide Material Compatibility

Dual-wavelength output (532nm/1064nm) provides enhanced absorption tuning, making the machine adaptable to a variety of substrates, from optically transparent crystals to opaque ceramics.

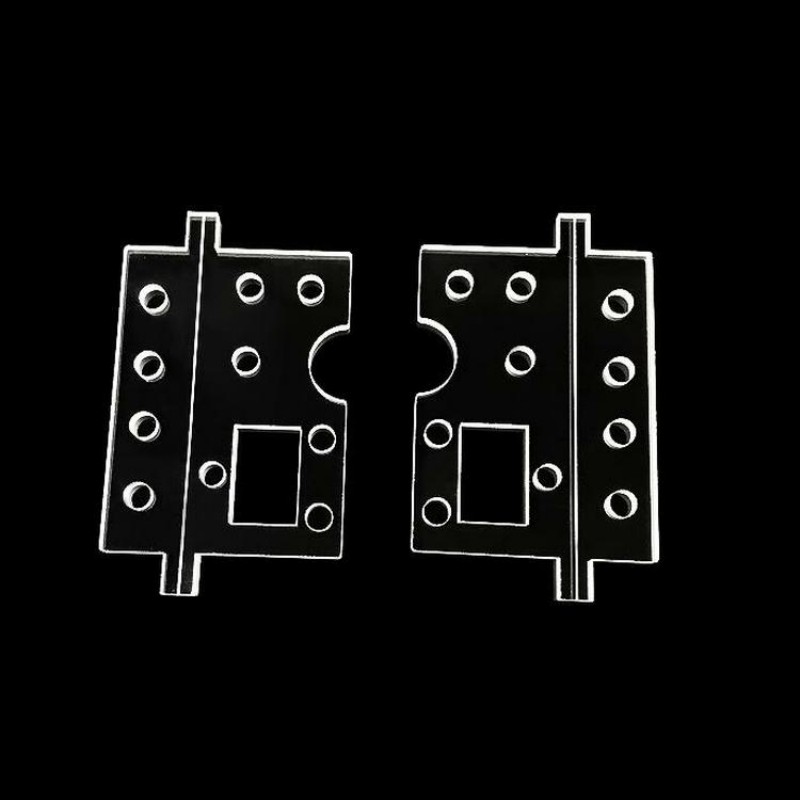

4. High-Speed, High-Precision Motion Control

With options for linear and direct-drive motors, the system supports high-throughput needs without compromising accuracy. Five-axis motion further enables complex pattern generation and multi-directional cuts.

5. Modular and Scalable Design

Users can tailor system configurations based on application demands—from lab-based prototyping to production-scale deployments—making it suitable across R&D and industrial domains.

Application Areas

Third-Generation Semiconductors:

Perfect for SiC and GaN wafers, the system performs dicing, trenching, and slicing with exceptional edge integrity.

Diamond and Oxide Semiconductor Machining:

Used for cutting and drilling high-hardness materials like single-crystal diamond and Ga₂O₃, with no carbonization or thermal deformation.

Advanced Aerospace Components:

Supports structural shaping of high-tensile ceramic composites and superalloys for jet engine and satellite components.

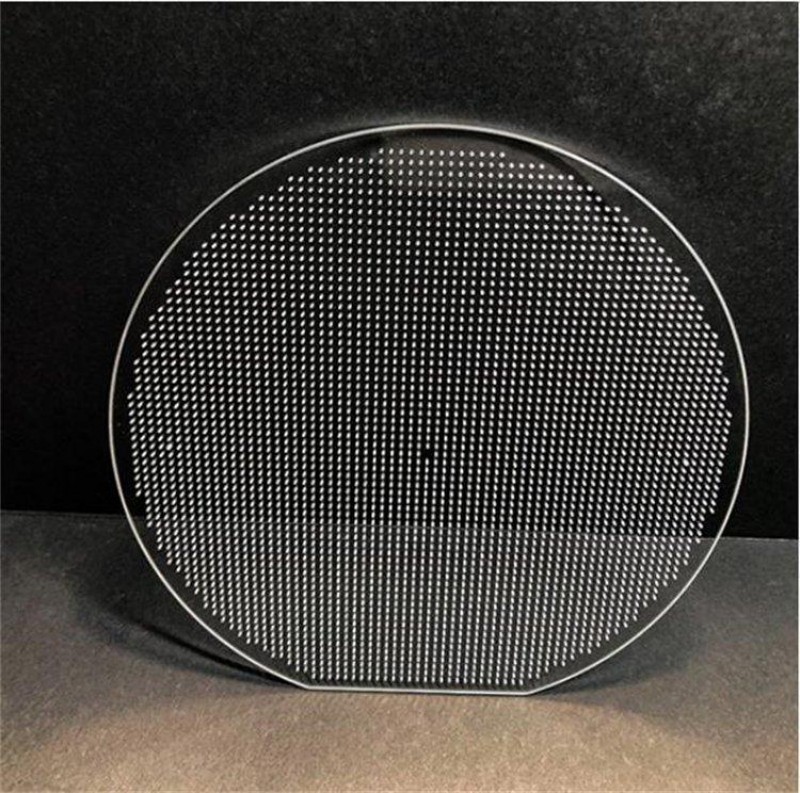

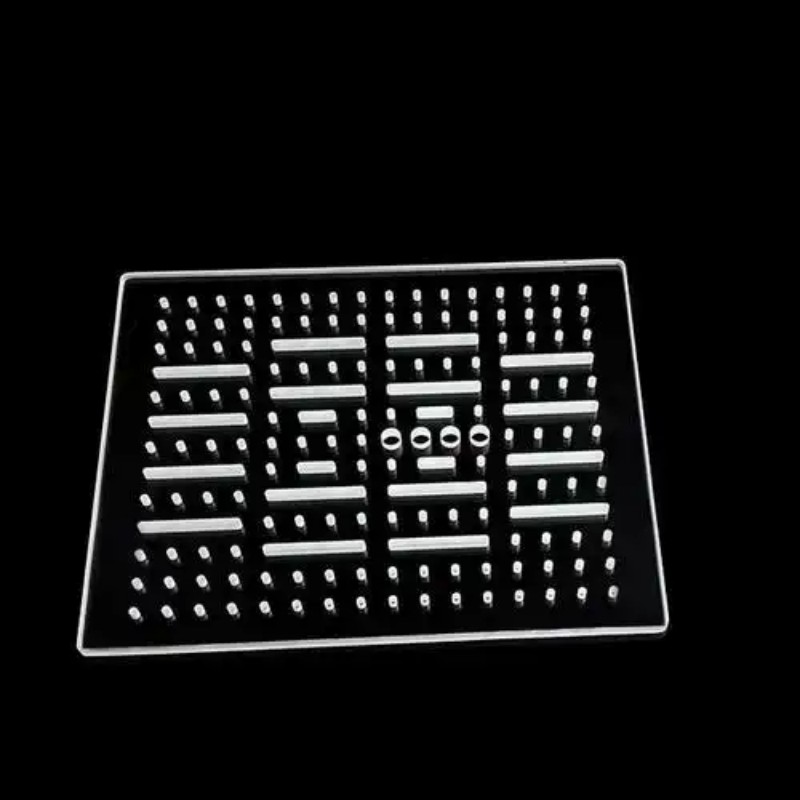

Photovoltaic and Ceramic Substrates:

Enables burr-free cutting of thin wafers and LTCC substrates, including through-holes and slot milling for interconnects.

Scintillators and Optical Components:

Maintains surface smoothness and transmission in fragile optical materials like Ce:YAG, LSO, and others.

Specification

|

Feature |

Specification |

| Laser Source | DPSS Nd:YAG |

| Wavelength Options | 532nm / 1064nm |

| Power Levels | 50 / 100 / 200 Watts |

| Precision | ±5μm |

| Cut Width | As narrow as 20μm |

| Heat Affected Zone | ≤5μm |

| Motion Type | Linear / Direct Drive |

| Supported Materials | SiC, GaN, Diamond, Ga₂O₃, etc. |

Why Choose This System?

● Eliminates typical laser machining issues like thermal cracking and edge chipping

● Improves yield and consistency for high-cost materials

● Adaptable for both pilot-scale and industrial use

● Future-proof platform for evolving materials science

Q&A

Q1: What materials can this system process?

A: The system is specially designed for hard and brittle high-value materials. It can effectively process silicon carbide (SiC), gallium nitride (GaN), diamond, gallium oxide (Ga₂O₃), LTCC substrates, aerospace composites, photovoltaic wafers, and scintillator crystals such as Ce:YAG or LSO.

Q2: How does the water-guided laser technology work?

A: It uses a high-pressure microjet of water to guide the laser beam via total internal reflection, effectively channeling laser energy with minimal scattering. This ensures ultra-fine focus, low thermal load, and precision cuts with line widths down to 20μm.

Q3: What are the available laser power configurations?

A: Customers can choose from 50W, 100W, and 200W laser power options depending on their processing speed and resolution needs. All options maintain high beam stability and repeatability.

Detailed Diagram