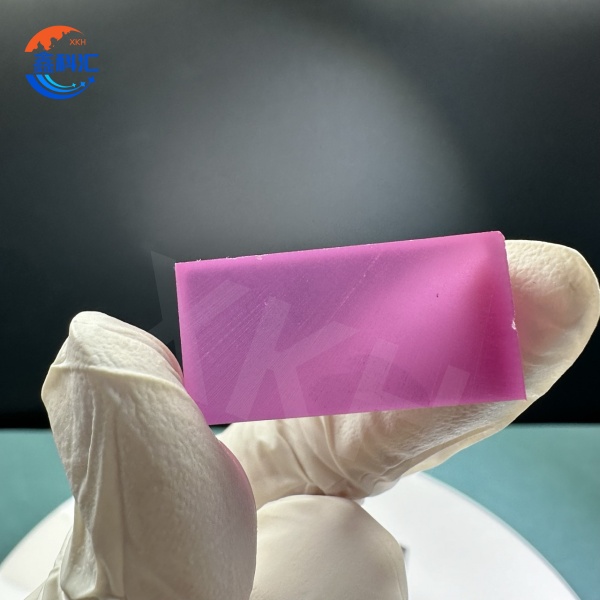

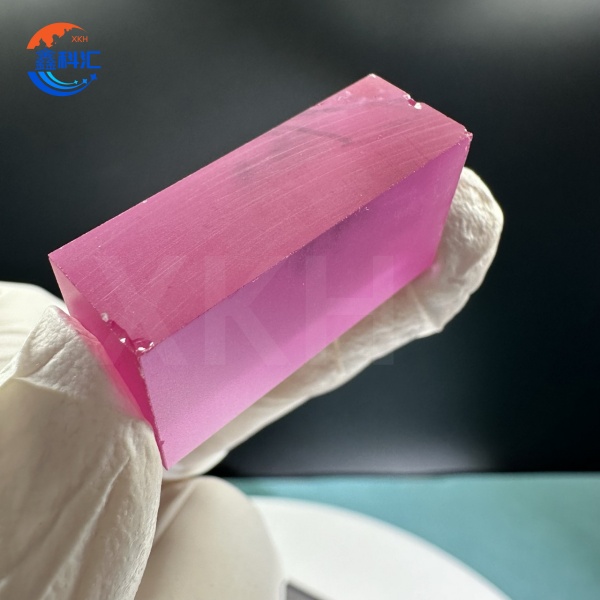

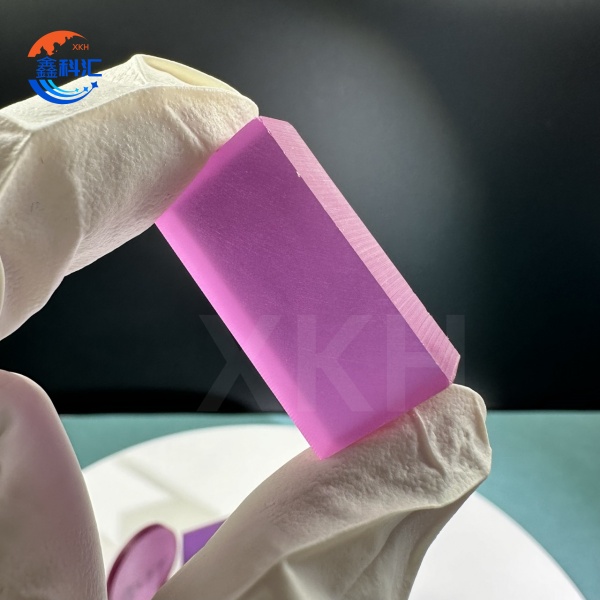

Laboratory-Grown Colored Sapphire gemstones Magenta Customized Jewelry & Watch Cases

Key Characteristics

- 1.Color Properties

· Spectral precision: First-principles calculations optimize Cr³⁺octahedral coordination, achieving 8nm FWHM absorption peaks at 610nm without natural color zoning

· Fluorescence: Weak orange-yellow emission (<500 counts/s/cm² @450nm under 365nm UV) minimizes interference in museum lighting

2.Physical Performance

· Environmental durability: <0.5% transmittance loss after 1000 thermal cycles (-200°C↔200°C); zero discoloration after 100h @800°C

· Mechanical strength: 2.5GPa compressive strength and >2GPa flexural strength (10× quartz) withstands 5000 drop tests

3.Crystal Quality

· Defect control: XRD-confirmed lattice parameters (a=4.758Å, c=12.991Å) match JCPDS#41-1468 with >99.9% consistency; TEM shows <10¹⁵/cm³ oxygen vacancies

· Scalability: 40% higher yield than Czochralski method for 80mm boules (15kg single-crystal weight)

4.Machinability

· Precision forming: CNC carves 0.1mm micro-features (e.g., tourbillon gears) meeting ISO 2768-m; laser engraving achieves ±1μm accuracy

· Surface finishing: MRF polishing delivers Ra<0.8nm with Mohs 9 scratch resistance (1kg load, <1μm indentation)

Primary Applications

1.Haute Horlogerie

- Watchcase innovation: "Biconic cutting" reduces 45mm case thickness to 1.2mm (vs. conventional 2.5mm) while increasing flexural strength to 2.2GPa

- Functional integration: Sputtered ITO films (<80Ω/□) enable touch-sensitive crowns with 85% wireless charging efficiency

2.Jewelry Design

- Gem cutting: 3-15ct emerald/brilliant cuts with 18K rose gold settings (Pantone 19-1664TPX to 19-2456TCX)

- Structural art: "Lattice hollowing" reduces 3ct stone weight by 40% while increasing transmittance to 89%

3.Industrial Solutions

- Optical filters: 610±5nm bandpass filters (OD5 blocking) enhance quantum-dot displays to 20000:1 contrast

- Radiation detection: X-ray sensors (<3keV resolution @59.5keV) deployed at CERN particle colliders

4.Collector's Items

- Art pieces: 80mm boules with museum-grade nitrogen encapsulation for exhibitions

- Educational specimens: Growth striations (30μm spacing) and dislocation networks (<10³/cm²) for MIT materials science curricula

XKH Services

XKH's Artificially Synthesized Colored Sapphire Business Overview

XKH utilizes chemical vapor deposition (CVD) and high-temperature fusion methods to efficiently cultivate artificially synthesized colored sapphires, covering a full spectrum of colors from magenta (CIE x=0.36) to deep blue (CIE x=0.05). By precisely controlling the doping ratios of aluminum oxide with transition metals (e.g., chromium, titanium) at 0.3–0.7wt% and employing 1700–2050°C high-temperature crystallization processes, the company breaks traditional color limitations, achieving >98% color purity, Mohs hardness 9, and >82% transmittance (400–700nm), meeting both jewelry and industrial-grade requirements.

In sales and supply, XKH establishes a global supply chain network, providing Swiss luxury watch brands with custom sapphire watch cases. Utilizing diamond wire cutting (wire diameter 50μm) and fluid polishing technology, it achieves 0.1mm microstructural precision, with case flexural strength exceeding 2GPa and scratch resistance up to Mohs 9. Through ISO 2768-m quality control, each batch ensures color deviation ΔE <0.5 and inclusion density <0.001%, aligning with stringent luxury industry standards.

Custom processing services span from ingot cutting to final polishing, supporting complex designs (e.g., spiral heat dissipation holes, nano-engraving) with ±0.001mm tolerance. For jewelry, XKH offers 3–15ct emerald/round cuts paired with 18K precious metal settings and developed a "lattice hollowing" technique, reducing 3ct gem weight by 40% while enhancing transmittance to 89%, ideal for dynamic light-art installations.

All products include blockchain traceability certificates, documenting the entire process from raw material melting to final delivery, meeting traceability demands in luxury and semiconductor sectors.

Through vertically integrated R&D-production and technology-service dual-drive, XKH transforms lab-grade materials into benchmark products for high-end consumer electronics and jewelry markets, and XKH is continuously leading the techno-aesthetic revolution in colored sapphires.