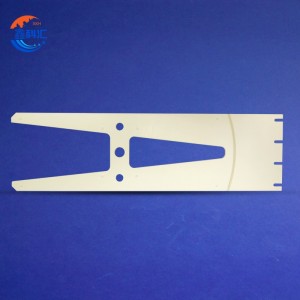

High-Performance Alumina Ceramic End Effector (Fork Arm) for Semiconductor and Cleanroom Automation

Detailed Diagram

Product Introduction

The Alumina Ceramic End Effector, also referred to as a ceramic fork arm or robotic ceramic hand, is a high-precision handling component designed for automated systems in semiconductor, photovoltaic, panel display, and high-purity laboratory environments. It is engineered to provide exceptional thermal stability, mechanical rigidity, and chemical resistance, offering clean, reliable, and safe transport of sensitive materials such as silicon wafers, glass substrates, and electronic micro-components.

As a type of robotic end effector, this ceramic component is the final interface between the automation system and the workpiece. It plays a critical role in precision transfer, alignment, loading/unloading, and positioning tasks in cleanrooms and vacuum environments.

Material Overview – Alumina Ceramic (Al₂O₃)

Alumina ceramic is a highly stable and chemically inert technical ceramic material known for its excellent mechanical and electrical properties. The high-purity (≥ 99.5%) alumina used in these end effectors ensures:

-

High hardness (Mohs 9): Second only to diamond, alumina provides extreme wear resistance.

-

High-temperature capability: Maintains structural integrity above 1600°C.

-

Chemical inertness: Resistant to acids, alkalis, solvents, and plasma etching environments.

-

Electrical insulation: With high dielectric strength and low dielectric loss.

-

Low thermal expansion: Ensures dimensional stability in thermal cycling environments.

-

Low particle generation: Essential for cleanroom compatibility (Class 10 to Class 1000).

These features make alumina ceramic ideal for mission-critical operations in contamination-sensitive industries.

Functional Applications

The alumina ceramic end effector is widely adopted in high-tech industrial processes, particularly where traditional metallic or plastic materials fall short due to thermal expansion, contamination, or corrosion issues. Key application fields include:

- Semiconductor wafer transfer

- Photolithography loading and unloading systems

- Glass substrate handling in OLED and LCD lines

- Crystalline silicon wafer transfer in solar cell production

- Automated optical or microelectronic inspection

- Sample transport in analytical or biomedical labs

- Vacuum environment automation systems

Its ability to perform without introducing particles or static charge makes it indispensable for precise robotic operations in cleanroom automation.

Design Features & Customization

Each ceramic end effector is engineered to fit a specific robotic arm or wafer handling system. We support full customization based on:

-

Wafer size compatibility: 2", 4", 6", 8", 12" and more

-

Slot geometry and spacing: Accommodates edge grip, back side support, or notched wafer designs

-

Suction ports: Integrated vacuum holes or channels for non-contact handling

-

Mounting configuration: Holes, threads, slots tailored to your robot’s end tool flange

-

Surface treatment: Polished, lapped, or fine-ground finish (Ra < 0.2 µm available)

-

Edge protection: Rounded corners or chamfering to avoid wafer damage

By using CAD drawings or 3D models provided by customers, our engineers can optimize each fork arm for weight, strength, and cleanliness.

Advantages of Ceramic End Effectors

| Feature | Benefit |

|---|---|

| High Mechanical Rigidity | Maintains dimensional precision under robotic loading forces |

| Excellent Thermal Performance | Performs reliably in high-temp or plasma environments |

| Zero Metal Contamination | No risk of ion contamination in critical semiconductor processing |

| Low Friction Surface | Reduces scratch risk on wafer or glass substrates |

| Anti-Static and Non-Magnetic | Does not attract dust or affect magnetic-sensitive components |

| Long Service Life | Superior wear resistance in repetitive high-speed automation cycles |

| Ultra-Clean Compatibility | Suitable for ISO 14644 cleanrooms (Class 100 and below) |

Compared to plastic or aluminum arms, alumina ceramic provides dramatically improved chemical and physical stability with minimal maintenance requirements.

| Property | Metal Arm | Plastic Arm | Alumina Ceramic Arm |

|---|---|---|---|

| Hardness | Moderate | Low | Very High (Mohs 9) |

| Thermal Stability | ≤ 500°C | ≤ 150°C | ≥ 1600°C |

| Chemical Resistance | Moderate | Poor | Excellent |

| Cleanroom Suitability | Medium | Low | Very High |

| Wear Resistance | Medium | Low | Outstanding |

| Dielectric Strength | Low | Medium | High |

| Custom Machining Precision | Limited | Moderate | High (±0.01mm possible) |

Technical Specifications

| Parameter | Value |

|---|---|

| Material | High-purity Alumina (≥ 99.5%) |

| Working Temperature | Up to 1600°C |

| Surface Roughness | Ra ≤ 0.2 µm (optional) |

| Compatible Wafer Sizes | 2" to 12" or custom |

| Flatness Tolerance | ±0.01 mm (application dependent) |

| Vacuum Suction Support | Optional, customizable channels |

| Mounting Options | Bolt-through, flange, slotted holes |

Frequently Asked Questions (FAQ)

Q1: Can the end effector be integrated into existing robotic systems?

A1: Yes. We support customization based on your robotic interface. You can send us a CAD drawing or flange dimensions for precise adaptation.

Q2: Will ceramic arms break easily during use?

A2: While ceramic is brittle by nature, our designs use optimized geometry to minimize stress concentration. Under proper use conditions, they provide significantly longer service life than metal or plastic.

Q3: Is it possible to use this in ultra-high vacuum or plasma etching chambers?

A3: Yes. Alumina ceramic is non-outgassing, thermally stable, and corrosion resistant—perfectly suitable for high-vacuum, reactive gas, or plasma environments.

Q4: How are these components cleaned or maintained?

A4: They can be cleaned using DI water, alcohol, or cleanroom-compatible detergents. No special maintenance is needed due to their chemical stability and inert surface.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.