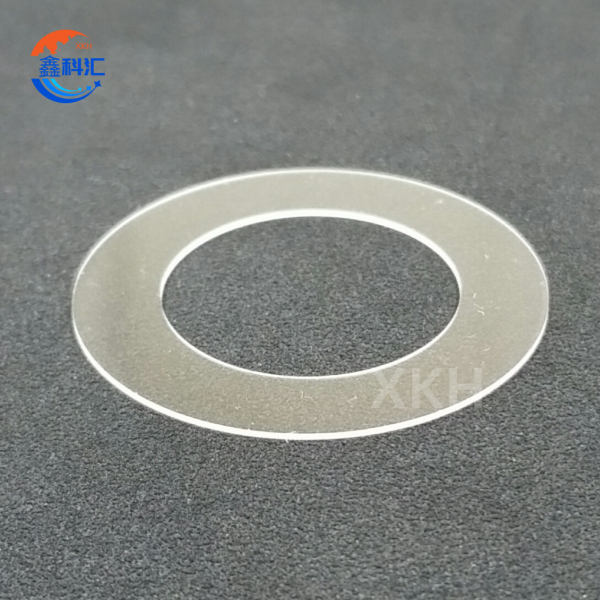

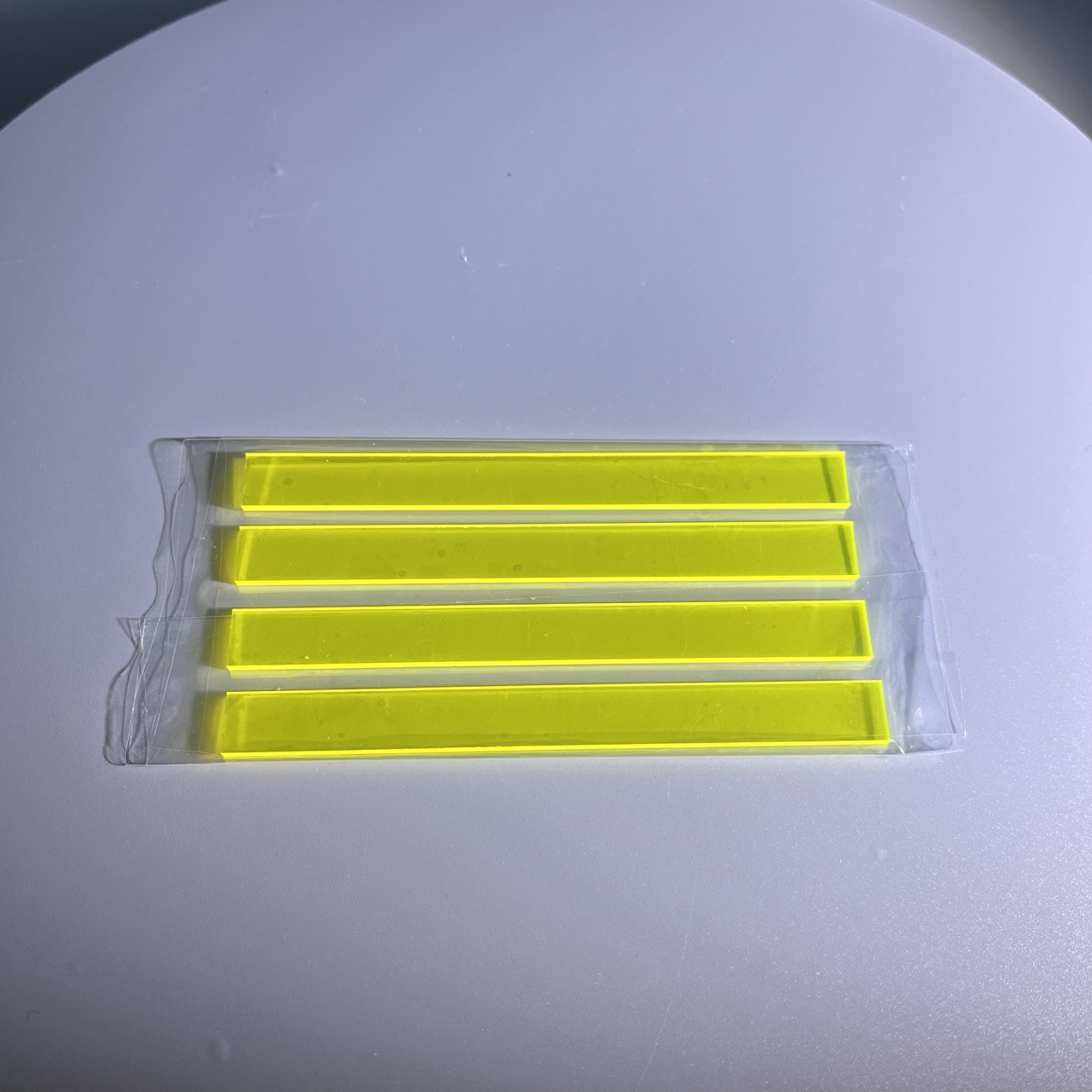

Customized Shaped Sapphire Optical Windows Sapphire Components with Precision Polishing

Technical parameters

| Sapphire window | |

| Dimension | 8-400mm |

| Dimensional tolerance | +0/-0.05mm |

| Surface quality(scratch&dig) | 40/20 |

| Surface accuracy | λ/10per@633nm |

| Clear Aperture | >85%,>90% |

| Parallelism tolerance | ±2''-±3'' |

| Bevel | 0.1-0.3mm |

| Coating | AR/AF/upon customer request |

Key Features

1.Material Superiority

· Enhanced Thermal Properties: Exhibits thermal conductivity of 35 W/m·K (at 100°C), with a low thermal expansion coefficient (5.3×10⁻⁶/K) that prevents optical distortion under rapid temperature cycling. The material maintains structural integrity even during thermal shock transitions from 1000°C to room temperature in seconds.

· Chemical Stability: Demonstrates zero degradation when exposed to concentrated acids (HF excluded) and alkalis (pH 1-14) for prolonged periods, making it ideal for chemical processing equipment.

· Optical Refinement: Through advanced C-axis crystal growth, achieves >85% transmission in the visible spectrum (400-700nm) with scatter losses below 0.1%/cm.

· Optional hyper-hemispherical polishing reduces surface reflections to <0.2% per surface at 1064nm.

2.Precision Engineering Capabilities

· Nanoscale Surface Control: Utilizing magnetorheological finishing (MRF), achieves surface roughness <0.3nm Ra, critical for high-power laser applications where LIDT exceeds 10J/cm² at 1064nm, 10ns pulses.

· Complex Geometry Fabrication: Incorporates 5-axis ultrasonic machining for creating microfluidic channels (50μm width tolerance) and diffractive optical elements (DOE) with <100nm feature resolution.

· Metrology Integration: Combines white-light interferometry and atomic force microscopy (AFM) for 3D surface characterization, ensuring form accuracy <100nm PV across 200mm substrates.

Primary Applications

1.Defense Systems Enhancement

· Hypersonic Vehicle Domes: Engineered to withstand Mach 5+ aerothermal loads while maintaining MWIR transmission for seeker heads. Special nanocomposite edge seals prevent delamination under 15G vibration loads.

· Quantum Sensing Platforms: Ultra-low birefringence (<5nm/cm) versions enable precision magnetometry in submarine detection systems.

2.Industrial Process Innovation

· Semiconductor Extreme UV Lithography: Grade AA polished windows with <0.01nm surface roughness minimize EUV (13.5nm) scattering losses in stepper systems.

· Nuclear Reactor Monitoring: Neutron-transparent variants (Al₂O₃ isotopically purified) provide real-time visual monitoring in Gen IV reactor cores.

3.Emerging Technology Integration

· Space-Based Optical Comms: Radiation-hardened versions (after 1Mrad gamma exposure) maintain >80% transmission for LEO satellite laser crosslinks.

· Biophotonics Interfaces: Bio-inert surface treatments enable implantable Raman spectroscopy windows for continuous glucose monitoring.

4.Advanced Energy Systems

· Fusion Reactor Diagnostics: Multi-layer conductive coatings (ITO-AlN) provide both plasma viewing and EMI shielding in tokamak installations.

· Hydrogen Infrastructure: Cryogenic-grade versions (tested to 20K) prevent hydrogen embrittlement in liquid H₂ storage viewports.

XKH Services & Supply Capabilities

1.Custom Manufacturing Services

· Drawing-Based Customization: Supports non-standard designs (1 mm to 300 mm dimensions), 20-day rapid delivery, and first-time prototyping within 4 weeks.

· Coating Solutions: Anti-reflection (AR), anti-fouling (AF), and wavelength-specific coatings (UV/IR) to minimize reflection losses.

· Precision Polishing & Testing: Atomic-level polishing achieves ≤0.5 nm surface roughness, with interferometry ensuring λ/10 flatness compliance.

2.Supply Chain & Technical Support

· Vertical Integration: Full-process control from crystal growth (Czochralski method) to cutting, polishing, and coating, guaranteeing material purity (void-/boundary-free) and batch consistency.

· Industry Collaboration: Certified by aerospace contractors; partnered with CAS to develop superlattice heterostructures for domestic substitution.

3.Product Portfolio & Logistics

· Standard inventory: 6-inch to 12-inch wafer formats; unit pricing from 43to82 (size/coating-dependent), with same-day shipping.

· Technical consultation for application-specific designs (e.g., stepped windows for vacuum chambers, thermal shock-resistant structures).