Custom Sapphire Optical Window 222mm × 74mm × 4mm for high temperature

Detailed Diagram

Overview

Sapphire windows are high-performance optical components widely used in laser systems, aerospace, military equipment, industrial inspection, and scientific research. Made from high-quality sapphire single crystals, they offer exceptional transparency, hardness, high-temperature resistance, and chemical corrosion resistance. These properties enable sapphire windows to maintain stable optical performance in extreme environments, providing high optical transmission while effectively protecting optical devices from external environmental factors. Sapphire windows are essential components in high-tech devices.

Manufacturing Process

-

Exceptional Optical Performance

Sapphire windows have high optical transmission, typically above 85%, across ultraviolet, visible, and near-infrared wavelengths. This ensures excellent optical performance and data accuracy, crucial for high-precision applications. -

High Hardness and Wear Resistance

Sapphire ranks second only to diamond on the Mohs hardness scale with a rating of 9. This gives sapphire windows exceptional resistance to scratching and physical damage, making them suitable for use in high-pressure or abrasive environments. -

High-Temperature and Thermal Stability

Sapphire can withstand extremely high temperatures, up to 2000°C, and is particularly well-suited for high-temperature optical systems and applications in harsh thermal conditions. -

Chemical Corrosion Resistance

Sapphire is highly resistant to most acids, alkalis, and solvents, maintaining its stability even in highly corrosive environments, making it ideal for demanding optical applications. -

Mechanical Strength and Shock Resistance

Sapphire windows are not only hard but also have high mechanical strength, allowing them to withstand high-pressure, intense vibrations, and other mechanical stresses without compromising optical performance.

Manufacturing Process

-

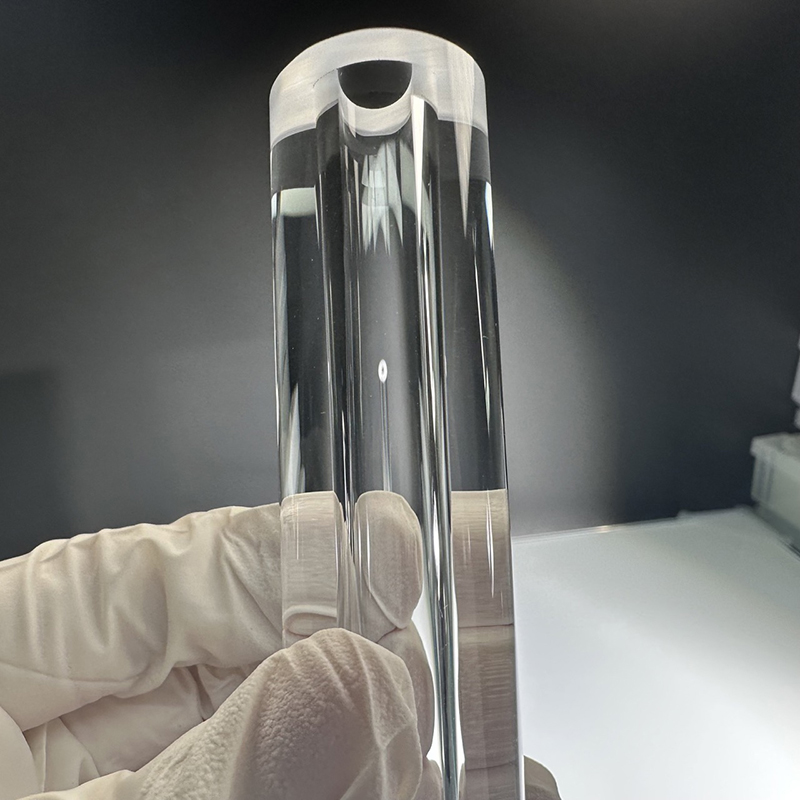

Sapphire Crystal Growth

The production of sapphire windows begins with sapphire crystal growth. High-quality sapphire crystals are grown using methods such as Verneuil process or Czochralski process. These methods allow for the production of crystals with specific optical and mechanical properties to meet the exact requirements of the final window product. -

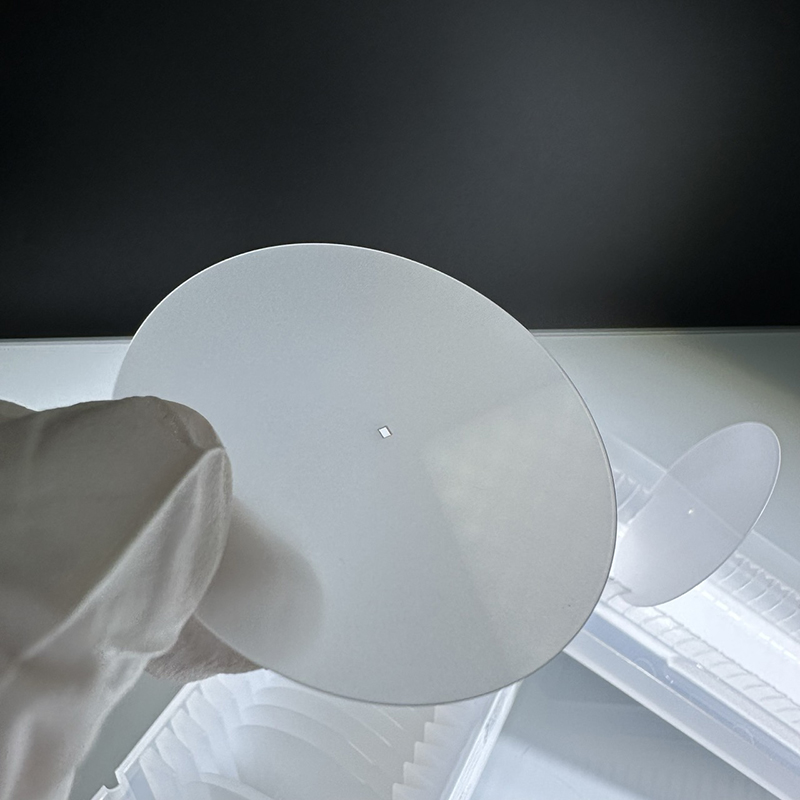

Cutting and Polishing

Once the sapphire crystal is grown, it is precisely cut to the desired shape and size using diamond saws. The resulting sapphire blanks are then meticulously ground and polished to ensure a smooth surface with excellent optical clarity and minimal imperfections. -

Surface Treatment and Coating

To enhance the performance of sapphire windows, coatings such as anti-reflection coatings or hard coatings are applied to the surface. Anti-reflection coatings improve light transmission, while hard coatings increase the scratch resistance of the surface, extending the window’s durability. -

Quality Control and Inspection

Each sapphire window undergoes stringent quality checks to ensure it meets all optical, mechanical, and dimensional specifications. The inspection includes optical transmission testing, surface quality analysis, dimensional accuracy, and hardness testing.

Applications

Sapphire windows are used in a wide range of high-tech industries and applications due to their unique properties. Below are the primary areas where sapphire windows are commonly used:

-

Laser Systems

Due to their high light transmission and resistance to high-power lasers, sapphire windows are widely used in laser equipment, laser cutting systems, and laser scanning devices. They ensure efficient and stable laser operation. -

Aerospace

Sapphire windows are essential components in aerospace applications, such as satellites, spacecraft, and drones. Their high-temperature tolerance, radiation resistance, and ability to withstand atmospheric pressure make them ideal for space and high-altitude environments. -

Military and Defense

Sapphire windows are used in military optical devices such as infrared sensors, thermal imagers, night vision systems, and optical telescopes. Their hardness, durability, and chemical resistance ensure reliable optical performance in extreme conditions. -

Industrial Applications

In industrial environments, sapphire windows are used in sensors, detectors, and other optical equipment exposed to high temperatures, corrosive gases, or liquids. They protect the equipment and ensure stable operation under harsh conditions. -

Scientific Research

Sapphire windows are widely used in scientific instruments such as spectrometers, microscopes, and optical sensors. Their high optical transmission ensures precise and accurate experimental data, which is crucial for research applications. -

Medical Devices

Sapphire windows are used in medical devices like laser surgery equipment, endoscopes, and medical imaging systems. Their high hardness and transparency make them ideal for maintaining stable performance and durability in demanding medical environments. -

Automotive Industry

In the automotive industry, sapphire windows are used in LiDAR (Light Detection and Ranging) systems and advanced sensor systems for autonomous vehicles. The durability and scratch resistance of sapphire ensure reliable performance in challenging driving conditions. -

Electronics and Semiconductors

Sapphire windows are used in electronic and semiconductor devices, especially in high-precision optical inspection equipment and optical communication systems. They ensure the stability and reliability of these devices in high-performance environments.

Specifications and Customization Options

-

Sizes: Sapphire windows can be customized to various diameters and thicknesses according to customer requirements.

-

Surface Treatments: Various surface treatments, such as anti-reflective coatings or hard coatings, are available to improve durability and optical performance.

-

Optical Transmission: Custom optical transmission specifications can be provided for specific wavelength ranges to meet application needs.

FAQ

1. What is a sapphire window?

A sapphire window is an optical component made from single-crystal aluminum oxide (Al₂O₃). It is cut, polished, and used to protect, isolate, or transmit light in demanding environments due to its extreme hardness, wide transmission range, and durability.

2. What are the key features of sapphire windows?

-

Extreme hardness: Mohs 9, second only to diamond, highly scratch-resistant.

-

Wide transmission range: Transparent from UV to IR (150 nm – 5500 nm).

-

High thermal resistance: Stable operation above 1600 °C.

-

Chemical stability: Resistant to acids, alkalis, and solvents.

-

Mechanical strength: High strength, suitable for high-pressure or harsh environments.

3. What are the common applications?

-

Optics & lasers: Laser windows, protective optics.

-

Medical & industrial: Endoscopes, fiber-optic probes, scanning windows.

-

Defense & aerospace: IR detectors, protective domes and housings.

-

Consumer electronics: Luxury watch covers, smartphone and camera protection.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.