Single Crystal Ruby Rod

Detailed Diagram

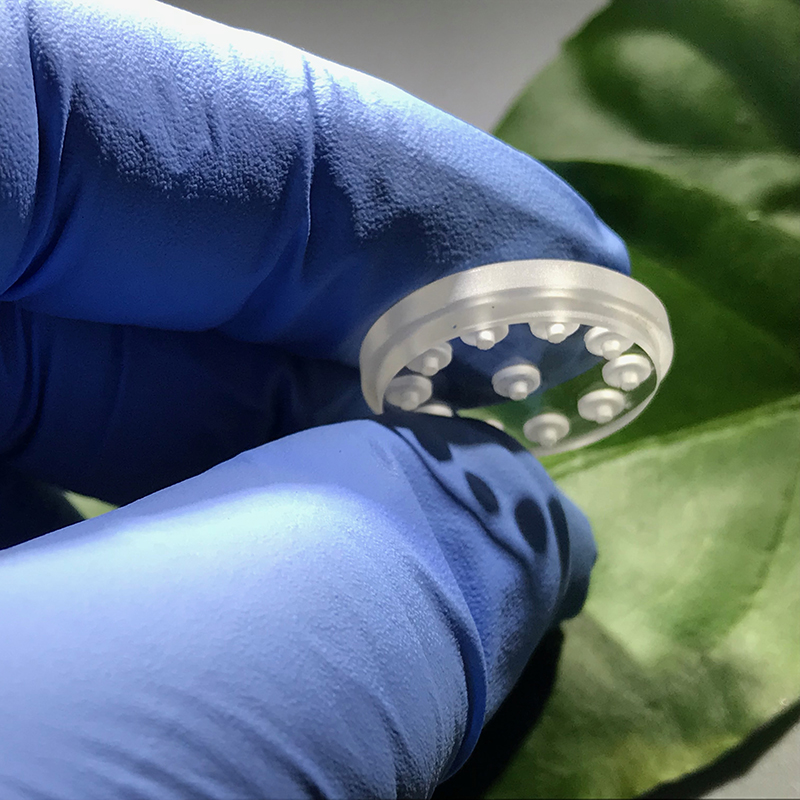

Overview of Ruby Bearings

The Ruby Rod is a precision-engineered single crystal component manufactured from chromium-doped aluminum oxide (Cr:Al₂O₃). Through controlled crystal growth and advanced machining processes, ruby rods exhibit a unique combination of optical functionality, extreme hardness, and long-term stability. These characteristics make ruby rods an ideal choice for laser systems, optical alignment applications, and high-wear industrial environments.

Compared with conventional ceramic or polycrystalline materials, single crystal ruby rods offer superior uniformity, predictable performance, and excellent resistance to thermal and chemical stress.

Crystal Growth and Processing ruby bearings

Ruby rods are grown using mature single crystal growth technologies such as the Czochralski (CZ) method or the Kyropoulos (KY) method. During crystal growth, chromium ions are uniformly incorporated into the corundum lattice, ensuring consistent color distribution, stable optical properties, and minimal internal defects.

After growth, the crystal ingots are oriented according to the specified crystallographic axis and processed through cutting, centerless grinding, fine grinding, and precision polishing. This ensures excellent dimensional accuracy, surface quality, and repeatability across production batches.

Typical Specifications (Customizable) ruby bearings

| Item | Specification |

|---|---|

| Material | Single Crystal Ruby (Cr: Al₂O₃) |

| Dopant | Chromium ions (Cr³⁺) |

| Color | Red |

| Crystal Growth Method | Czochralski (CZ) / Kyropoulos (KY) |

| Crystal Structure | Single crystal corundum |

| Crystal Orientation | C-axis / A-axis / Custom orientation |

| Diameter Range | 0.5 mm – 50 mm |

| Length Range | 5 mm – 300 mm |

| Surface Condition | Polished / Fine-ground / As-grown |

| Surface Roughness | Ra ≤ 0.05 μm (polished) |

| Dimensional Tolerance | ±0.01 mm (tighter tolerances available) |

| Mohs Hardness | 9 |

| Operating Temperature | ≤ 1600 °C |

| Chemical Stability | Excellent resistance to acids and alkalis |

Key Performance Benefits ruby bearings

-

High Optical Consistency: Uniform chromium distribution ensures stable optical behavior

-

Exceptional Hardness: Mohs hardness of 9 provides outstanding wear resistance

-

Thermal Reliability: Maintains structural and optical integrity at elevated temperatures

-

Chemical Durability: Suitable for corrosive or aggressive environments

-

Precision Machinability: Tight tolerances and high surface quality achievable

Application Areas ruby bearings

-

Solid-State Laser Systems: Ruby laser rods for pulsed laser and research applications

-

Optical Alignment & Positioning: Reference rods, alignment tools, and calibration components

-

Precision Instruments: Measuring probes, shafts, and support elements

-

Industrial Equipment: Wear-resistant rods used in high-load or high-temperature conditions

-

Research & Education: Experimental setups and laboratory demonstrations

Custom Manufacturing Capabilities ruby bearings

Ruby rods can be manufactured according to customer drawings or technical specifications. Custom options include diameter, length, crystal orientation, surface finish, chamfering, and end-face polishing. Both prototype quantities and mass production orders are supported.

FAQ of ruby bearings

Q1: What advantages do ruby rods have over sapphire rods?

Ruby rods and sapphire rods share the same Al₂O₃ crystal structure. The key difference is the chromium dopant in ruby, which provides red coloration and laser gain properties, making ruby rods suitable for laser and optical applications.

Q2: Can ruby rods be supplied for non-laser industrial use?

Yes. Due to their high hardness, wear resistance, and chemical stability, ruby rods are widely used in precision instruments and industrial equipment.

Q3: Are custom sizes and tolerances available?

Custom diameters, lengths, and tight tolerances are available based on application requirements.

Q4: What surface finishes can be provided?

Polished, fine-ground, and as-grown surface conditions can be supplied.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.