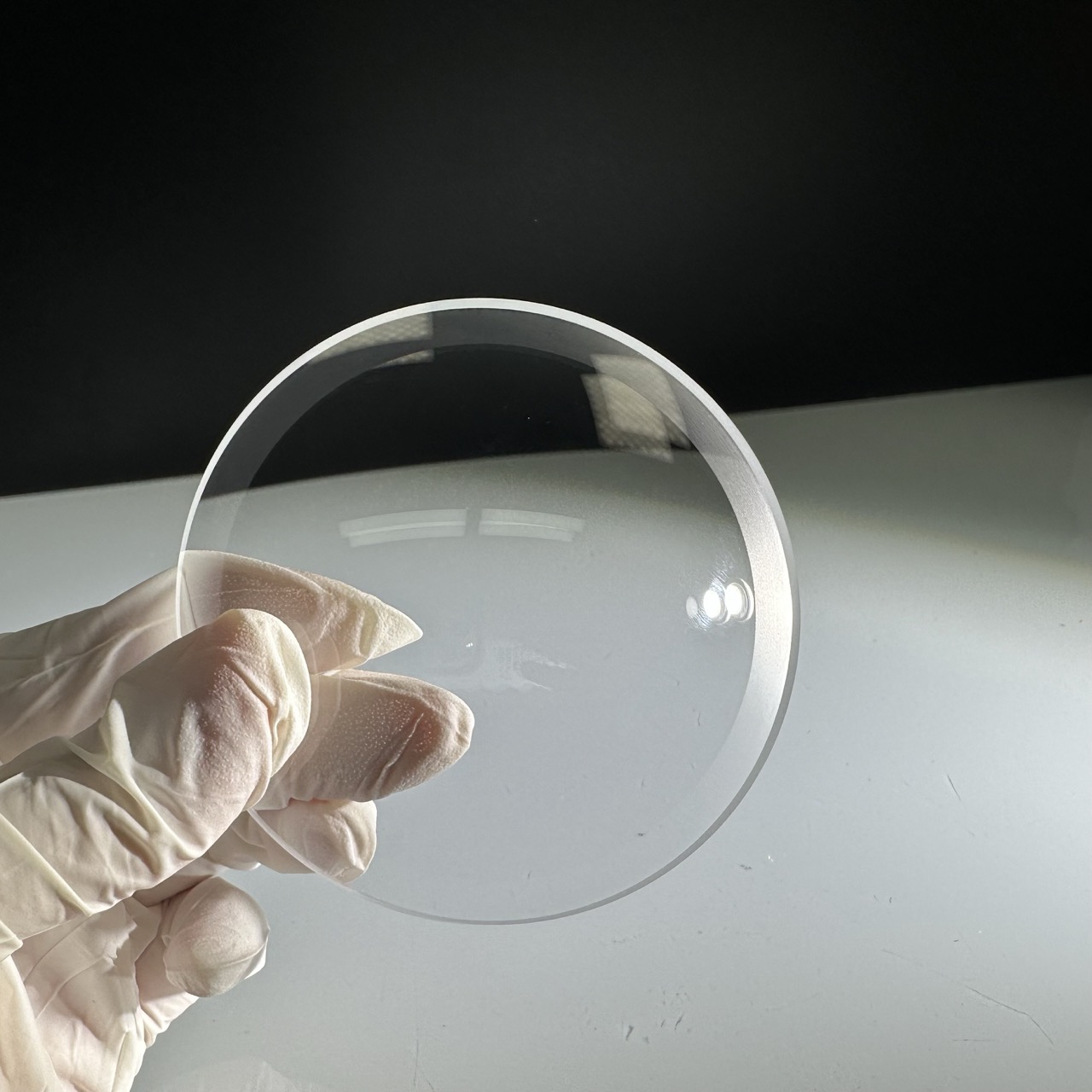

Silicon (Si) Infrared Lens with IR Anti-Reflection Coating

Detailed Diagram

Introduction Si lens

Silicon (Si) infrared lenses with IR anti-reflection coating are precision optical components developed for infrared optical systems that require high transmission efficiency, thermal stability, and mechanical reliability. Utilizing optical-grade single crystal silicon and advanced infrared coating technology, these lenses are optimized to minimize optical losses and enhance system-level performance in demanding infrared applications.

Due to its stable infrared transmission characteristics and excellent physical properties, silicon has become a widely adopted material for mid-infrared optical designs. When combined with a carefully engineered IR AR coating, silicon lenses provide a cost-effective and high-performance solution for modern infrared imaging and sensing systems.

Material Characteristics and Performance Advantages Si Lens

Silicon exhibits consistent infrared transmission within the 1.2–8 μm wavelength range and is especially well suited for 3–5 μm (MWIR) applications. Its intrinsic physical properties allow silicon lenses to maintain optical and mechanical stability even under challenging operating conditions.

Key material advantages include:

-

High thermal conductivity for efficient heat dissipation

-

Strong mechanical strength and resistance to thermal shock

-

Lower mass compared to germanium, enabling compact system design

-

Good environmental and chemical stability

-

Compatibility with precision optical fabrication processes

These characteristics make silicon lenses an excellent choice for infrared systems that must operate reliably over long periods or in fluctuating temperature environments.

Infrared Anti-Reflection Coating Design Si lens

Because silicon has a high refractive index, uncoated surfaces can introduce significant reflection losses. To address this, infrared anti-reflection coatings are applied to the lens surfaces to improve optical efficiency.

The IR AR coating is designed to:

-

Reduce Fresnel reflections at silicon–air interfaces

-

Increase effective transmission across the target infrared band

-

Improve image clarity, contrast, and detection sensitivity

-

Suppress stray reflections within optical assemblies

Coating designs can be optimized for specific wavelength ranges such as 3–5 μm (MWIR) or 8–12 μm (LWIR), as well as for custom infrared bands defined by system requirements.

Optical Design and Manufacturing Flexibility Si lens

Silicon infrared lenses with IR AR coating are available in a wide range of optical configurations to support diverse system designs:

-

Plano-convex, plano-concave, bi-convex, and bi-concave lenses

-

Spherical and custom aspherical geometries

-

Single-side or double-side IR anti-reflection coating

-

Precision polishing for controlled surface figure and roughness

Manufacturing processes are carefully controlled to ensure consistency in focal length, surface accuracy, and coating performance. Custom designs are supported for diameter, thickness, curvature, tolerance, and coating specifications.

Application Areas

Silicon lenses with IR anti-reflection coating are commonly used in:

-

Thermal imaging and infrared vision systems

-

Infrared detection and temperature measurement devices

-

Industrial monitoring and inspection equipment

-

Infrared spectroscopy and laboratory instrumentation

-

Infrared laser delivery and optical transmission systems

Their balanced performance and durability make them suitable for both commercial and industrial infrared applications.

Technical Specifications – Silicon (Si) Lens with IR Anti-Reflection Coating

| Parameter | Specification |

|---|---|

| Material | Optical Grade Single Crystal Silicon (Si) |

| Transmission Range | 1.2 – 8 μm |

| Typical Application Band | 3 – 5 μm (MWIR) |

| Optional Coating Band | 8 – 12 μm (LWIR), Custom IR Bands |

| Refractive Index | ~3.42 @ 3.9 μm |

| Lens Type | Plano-Convex / Bi-Convex / Plano-Concave / Bi-Concave |

| Surface Figure | ≤ λ/10 @ 3.39 μm (custom available) |

| Surface Quality | 60/40 or 40/20 (Scratch/Dig) |

| Diameter Tolerance | ±0.02 mm (custom available) |

| Center Thickness Tolerance | ±0.02 mm |

| Clear Aperture | ≥ 90% of Diameter |

| Surface Roughness | ≤ 5 nm RMS |

| AR Coating Type | Infrared Anti-Reflection (IR AR Coating) |

| Coating Design | Single-band or Multi-band IR AR |

| Average Reflectance (Ravg) | ≤ 1.0% per surface (design wavelength) |

| Coating Sides | Single-side or Double-side |

| Operating Temperature | -40 °C to +200 °C |

| Thermal Conductivity | ~150 W/m·K |

| Density | ~2.33 g/cm³ |

| Environmental Stability | Industrial Grade |

| Customization | Size, focal length, tolerances, coating available |

FAQ – Silicon (Si) Lens with IR Anti-Reflection Coating

1. What wavelength range is silicon suitable for in infrared applications?

Silicon lenses offer good infrared transmission in the 1.2–8 μm wavelength range and are most commonly used in the 3–5 μm (MWIR) band. Silicon is not recommended for visible or near-visible applications due to its low transmission in those regions.

2. Why is IR anti-reflection coating necessary for silicon lenses?

Silicon has a relatively high refractive index, which causes significant surface reflection on uncoated lenses. IR anti-reflection (AR) coating reduces these reflection losses, increases total transmission, and improves image contrast and signal-to-noise ratio in infrared optical systems.

3. What infrared wavelength bands can the AR coating be designed for?

The IR AR coating can be optimized for different wavelength ranges, including:

-

3–5 μm (MWIR)

-

8–12 μm (LWIR)

-

Custom infrared wavelength bands upon request

Coating performance can be tailored to specific system requirements.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.