Silicon Carbide Prism / Mirror For Infrared Optics Aerospace-Grade

Detailed Diagram

Overview

The silicon carbide (SiC) flat mirror is a premium optical component manufactured from advanced SiC ceramic. Featuring exceptional stiffness-to-weight ratio, superior infrared performance, and outstanding environmental durability, it is an ideal choice for demanding optical systems. Compared with traditional materials such as fused silica, germanium, and zinc selenide, SiC mirrors not only excel in the mid- to far-infrared spectrum but also deliver lightweight, high mechanical strength, and long-term stability under harsh operating conditions.

This mirror is widely adopted in aerospace payloads, laser systems, infrared imaging, and high-precision metrology.

Key Features

-

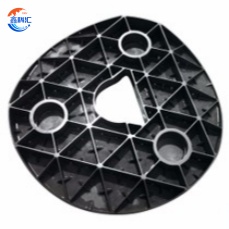

Lightweight structural optimization: Advanced design with honeycomb and topology structures minimizes weight without sacrificing strength.

Lightweight structural optimization: Advanced design with honeycomb and topology structures minimizes weight without sacrificing strength. -

Ultra-lightweight: Much lighter than conventional mirror substrates, essential for aerospace and mobile platforms.

-

High stiffness: Maintains surface figure accuracy even with large-aperture and thin-mirror configurations.

-

Low thermal expansion: Guarantees optical performance across rapid or extreme temperature variations.

-

Scratch & wear resistance: Hardness close to diamond, resistant to environmental abrasion.

-

High-precision surface finishing: Flatness ≤ 1 μm, surface quality suitable for demanding imaging and laser applications.

Performance Advantages

-

High modulus & dimensional stability: Elastic modulus up to 420–450 GPa, ensuring stable performance under heavy loads and vibrations.

-

Minimal thermal distortion: Very low coefficient of thermal expansion (CTE), ensuring optical stability in variable thermal environments.

-

Thermal shock & corrosion resistance: Stable against acid/alkali environments and resistant to rapid temperature fluctuations.

-

Dense, pore-free microstructure: Bulk density up to 3.14 g/cm³ with no residual porosity after machining, providing excellent reflectivity and structural integrity.

Applications

-

Infrared optics: Mid- and far-infrared imaging systems, thermal cameras, and surveillance optics.

-

Laser & optoelectronics: High-power laser mirrors, beam steering, and reflective optical assemblies.

-

Aerospace & astronomy: Space telescope mirrors, satellite payloads, and airborne optical instruments.

-

Defense & security: IR guidance systems, targeting mirrors, and night vision optics.

-

Precision metrology: Interferometry, flatness testing, and reference optics for calibration.

FAQ

Q1: Is SiC mirror reflective in visible wavelengths?

A1: The substrate itself is opaque, but with appropriate reflective coatings (metallic or dielectric), SiC flat mirrors can operate effectively in visible, infrared, and even laser wavelengths.

Q2: What advantages does SiC offer over glass or metal mirrors?

A2: SiC is significantly lighter, stiffer, and more thermally stable than glass or metal substrates. It is also far more durable in harsh or space environments.

Q3: Can SiC flat mirrors be used in high-power laser applications?

A3: Yes. With excellent thermal conductivity and mechanical stability, SiC substrates are ideal for high-power or high-energy laser mirrors when paired with suitable coatings.

Q4: What level of flatness can be achieved?

A4: After ultra-precision polishing, flatness can reach ≤ 1 μm, with parallelism and surface roughness controlled to meet stringent optical specifications.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.