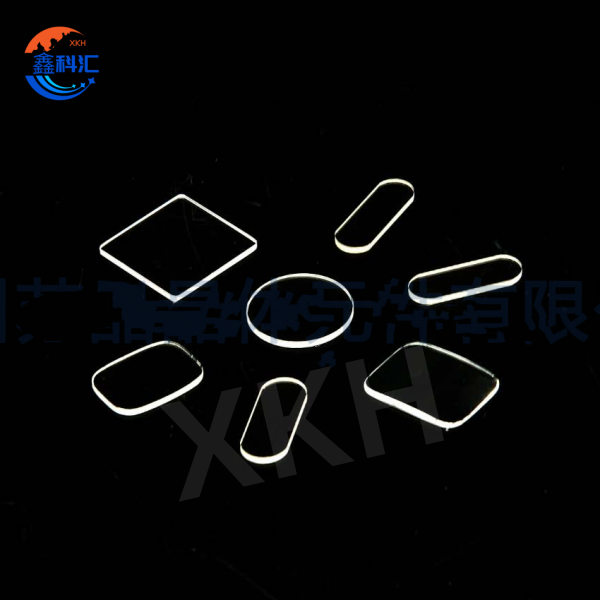

Sapphire Windows Optical Glass Customized Size Mohs hardness 9

Technical specification

| Category | Parameter | Typical Value / Range |

| Material Properties | Material Type | Single-crystal α-Alumina (Al₂O₃) |

| Transmission Range | 0.15μm ~ 5.5μm | |

| Refractive Index | 1.76 @ 589nm | |

| Thermal Expansion Coefficient | 5.3×10⁻⁶/K @ 20°C | |

| Thermal Conductivity | 25~35 W/(m·K) | |

| Dimensional Parameters | Outer Diameter (OD) | 1mm ~ 300mm |

| Inner Diameter (ID) | 0.5mm ~ 250mm | |

| Wall Thickness | 0.3mm ~ 20mm | |

| Length / Thickness | 0.3mm ~ 20mm | |

| Dimensional Tolerance | ±0.1mm (standard), ±0.01mm (high-precision) | |

| Coaxiality | ≤0.05mm (high-precision grade) | |

| Surface Finish | 10/5 (MIL-PRF-13830B) | |

| Surface Flatness | λ/8 @ 632.8nm | |

| Applications | Laser Systems | High-power laser windows, cavity mirrors |

| Infrared Optics | Thermal imaging, missile domes |

Key Features

-

-

- 1.Material Superiority

· Ultra-High Hardness: With a Mohs hardness of 9, sapphire outperforms quartz and plastics, resisting abrasion in industrial sensors and LiDAR optics.

· Broad Spectral Transmission: >85% transmittance from 200nm (UV) to 6μm (mid-IR), enabling multi-spectral applications like UV curing and quantum communication.

· Extreme Environment Resistance: Survives -200°C to 2000°C thermal cycling, pH 1-14 chemical exposure, and radiation doses exceeding 10⁶ Gy.

2.Aspheric Design

· Optical Aberration Correction: Non-spherical, free-form, and elliptical geometries eliminate spherical aberrations, enhancing imaging resolution (e.g., LiDAR beam divergence reduction).

· Complex Integration: Combines infrared windows with heat-dissipation structures for thermal management in high-power laser systems.

3.Functional Coatings

· Anti-Reflective Coatings (AR): Achieve <0.5% reflectivity via e-beam evaporation, boosting efficiency in 400G optical modules.

· Bandpass Filters: Selective transmission (e.g., 940nm IR) for LiDAR and quantum systems.

- 1.Material Superiority

-

Applications

1.Optical Communication & Laser Systems

· High-Speed Modules: Used in 400G/800G laser diode packaging (e.g., Huawei QSFP-DD), ensuring low-loss signal transmission.

· Industrial Lasers: Withstand >10kW/cm² power density in CO₂ laser cutting systems (e.g., Trumpf TruDisk lasers).

2.Medical Imaging

· Endoscopes: Corrosion resistance in bodily fluids (e.g., Olympus EVIS LUCERA) for high-definition gastrointestinal diagnostics.

· Infrared Thermography: Enhanced low-light detection in FLIR T1020 systems for electrical inspection.

3.Aerospace & Defense

· Satellite Payloads: Survive -196°C to +120°C thermal extremes in high-resolution Earth observation (e.g., Gaofen-7 satellite).

· Missile Guidance: Infrared windows for target acquisition in high-speed flight (e.g., AIM-120 AMRAAM).

4.Automotive & Industrial Sensing

· LiDAR Systems: Improve detection range in adverse weather (e.g., Velodyne VLP-32C).

· High-Temperature Sensors: Monitor furnaces (>1500°C) and chemical reactors (e.g., Siemens SITRANS LR250).

5.Quantum Technologies

· Single-Photon Detectors: Enable low-noise, high-efficiency quantum communication systems.

Company Services

1.Custom Development

· Complex Geometries: Accept CAD/3D models (STEP/IGES) with ±0.001mm tolerance for non-standard shapes (e.g., spiral heat-dissipation windows).

· Multi-Layer Coatings: Custom AR, bandpass, and dichroic filters (e.g., 98% transmittance at 940nm via ion-beam sputtering).

2.Mass Production

· Automated Manufacturing: 500,000+ units/month with 99.5% yield, supporting 7–15 day prototypes and 30-day bulk orders.

· Quality Assurance: ISO 9001-certified, with third-party validation (surface defects <5μm, transmittance >85%).

3.Technical Support

· Failure Analysis: Resolve coating delamination via optimized annealing (e.g., 850°C thermal cycles).

· Lifetime Warranty: 10-year military-grade support with annual recalibration (e.g., thermal imaging window alignment).

4.Cost Optimization

· Material Innovation: Kyropoulos growth reduces raw material costs by 30%, enabling consumer electronics (e.g., smartphone camera lenses).

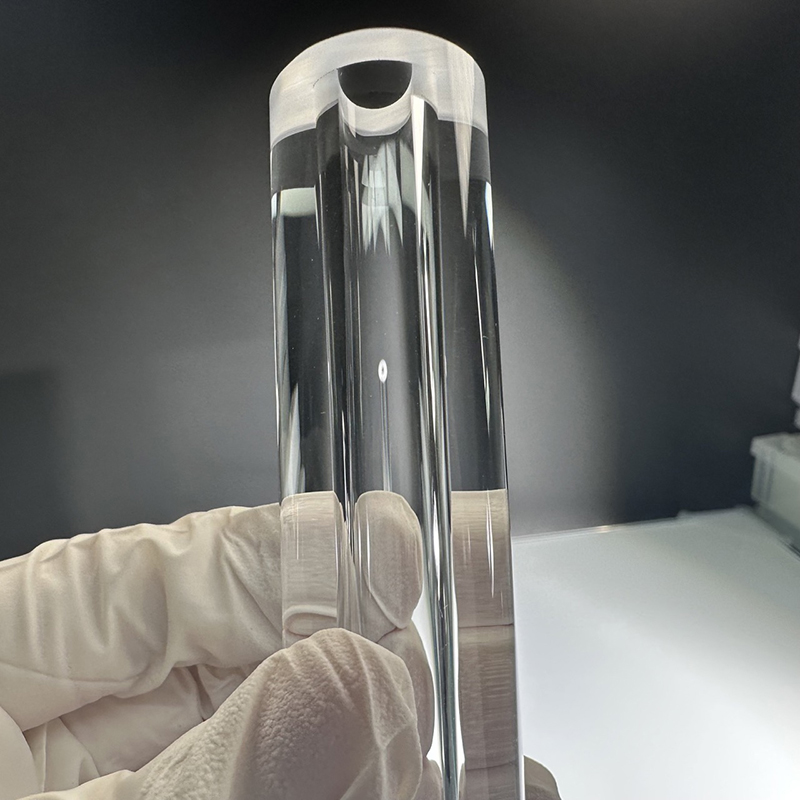

· Advanced Polishing: Magnetorheological finishing (MRF) achieves Ra <1nm surface roughness.

5.Global Collaboration

· R&D Partnerships: Collaborate with Tsinghua University on sapphire photonic substrates for LED efficiency enhancement.

· Certifications: RoHS/REACH-compliant, exported to North America, Europe, and Asia-Pacific markets.

Conclusion

Sapphire optical windows merge material resilience with design flexibility, setting benchmarks in defense, healthcare, and telecommunications. Engineered from synthetic sapphire (α-Al₂O₃), these windows leverage a Mohs hardness of 9 and thermal stability up to 2053°C to outperform conventional materials in extreme environments. XKH "Material-Process-Service" integrated approach combines precision diamond-turning, ion-beam sputtering, and AI-driven metrology to deliver tailored solutions—from hypersonic missile domes withstanding 2000°C thermal shocks to autoclave-sterilizable endoscopes for medical robotics. By deploying multi-layer DLC coatings and zero-birefringence crystal cuts, we achieve >99% transmittance at 1550nm for telecom systems and sub-nanometer surface roughness for EUV lithography. Certified to MIL-PRF-13830B and ISO 9001, our windows enable breakthroughs in quantum sensing (photon-counting detectors) and space-grade satellite payloads with 15-year radiation hardness. Through rapid prototyping (5-day turnaround) and global supply chain agility, we empower industries to overcome technical barriers, driving innovation in sustainability, miniaturization, and mission-critical reliability worldwide.