Sapphire Square Seed Crystal – Precision-Oriented Substrate for Synthetic Sapphire Growth

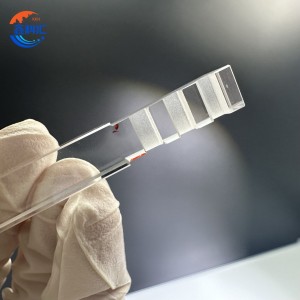

Detailed Diagram of Sapphire Seed Crystal

Overview of Sapphire Seed Crystal

A sapphire seed crystal is a small, highly pure piece of single-crystal aluminum oxide (Al2O3) that serves as the starting point for growing large sapphire boules. Acting like a “template,” it determines the lattice orientation, crystal structure, and overall quality of the synthetic sapphire that forms from it.

Only Sapphire Seed Crystal with 99.99% or higher purity and perfect crystalline structure are used, because any defect will transfer to the grown sapphire, affecting its optical clarity and mechanical performance. Seed crystals are the hidden but crucial foundation behind every high-quality sapphire product — from LED substrates and semiconductor wafers to aerospace optics and luxury watch covers.

How Sapphire Seed Crystals Are Made

The manufacturing of sapphire seed crystals is a precision-controlled process involving several critical steps:

- Master Sapphire Selection – Large, defect-free sapphire boules are chosen as the source material.

- Crystal Orientation Determination – Using X-ray diffraction, the boule’s crystallographic directions (C-plane, A-plane, R-plane, or M-plane) are mapped.

- Precision Cutting – Diamond wire saws or laser systems cut the boule into small wafers, rods, or square blocks with exact orientation.

- Polishing & Surface Processing – Each seed undergoes ultra-fine polishing and chemical treatment to remove micro-scratches and ensure an atomically smooth surface.

- Cleaning & Quality Control – Chemical cleaning eliminates contaminants, and each seed is inspected for orientation accuracy, purity, and structural integrity before shipment.

This process guarantees that every sapphire seed crystal can withstand extreme heat and reliably direct the growth of new sapphire.

Applications – How Sapphire Seed Crystals Enable Sapphire Growth

The sole function of sapphire seed crystals is to grow new synthetic sapphire, but they are indispensable across nearly all modern sapphire production methods.

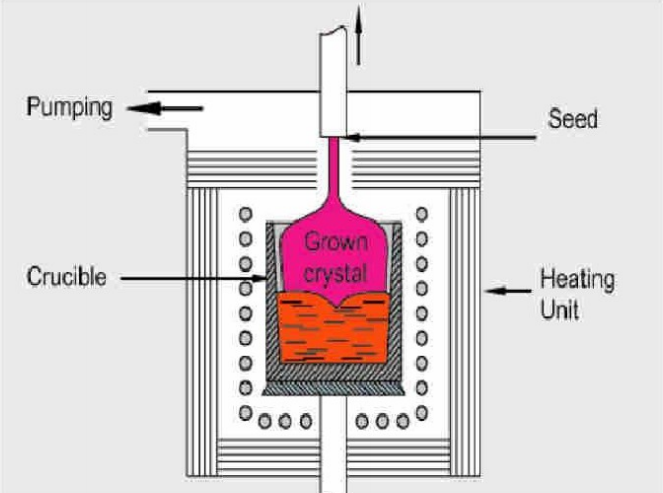

Kyropoulos Method (KY)

The Sapphire Seed Crystal is placed into molten alumina and gradually cooled, causing sapphire to grow outward from the seed. KY produces large, low-stress sapphire boules ideal for LED substrates and optical windows.

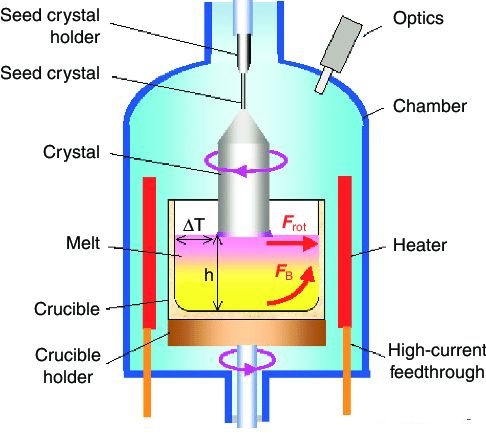

Czochralski Method (CZ)

The Sapphire Seed Crystal is attached to a pulling rod, dipped into the molten material, then slowly lifted and rotated. The sapphire “pulls” from the melt along the seed’s lattice, creating highly uniform crystals for optical and scientific use.

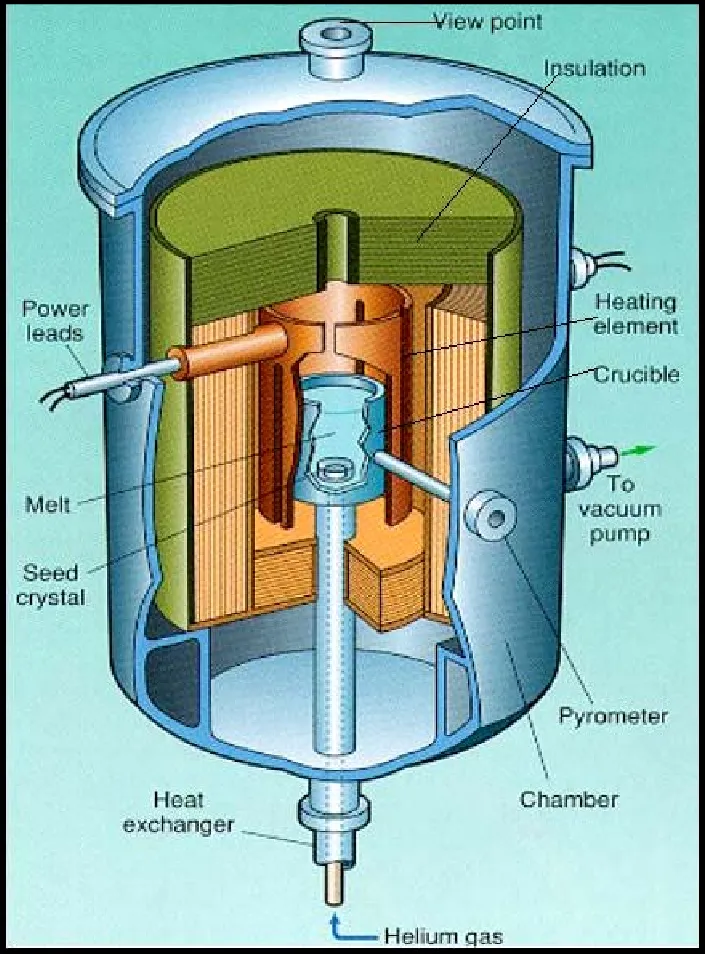

Heat Exchange Method (HEM)

The Sapphire Seed Crystal rests at the bottom of the crucible, and sapphire grows upward as the furnace cools from below. HEM can create large blocks of sapphire with minimal internal stress, widely used for aerospace windows and laser optics.

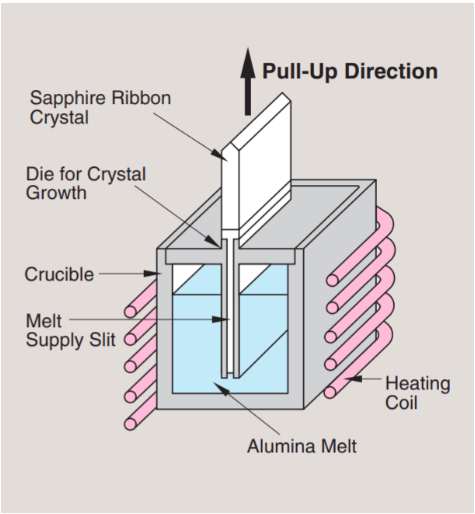

Edge-defined Film-fed Growth (EFG)

The Sapphire Seed Crystal crystal sits at the mold’s edge; molten alumina feeds via capillary action, growing sapphire in special shapes like rods, tubes, and ribbons.

FAQ of Sapphire Seed Crystal

Q1: Why are sapphire seed crystals important?

They define the crystal orientation and lattice structure of the grown sapphire, ensuring uniformity and preventing defects.

Q2: Can seed crystals be reused?

Some seeds may be reused, but most manufacturers prefer fresh seeds to maintain quality and avoid contamination.

Q3: What orientations are commonly used?

C-plane (for LED substrates), A-plane, R-plane, and M-plane, depending on the desired sapphire application.

Q4: Which growth methods depend on seed crystals?

All major modern methods — KY, CZ, HEM, EFG — require seed crystals.

Q5: What industries indirectly rely on seed crystals?

Any field using synthetic sapphire — LED lighting, semiconductor electronics, defense optics, luxury watches — ultimately depends on sapphire seed crystals.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.