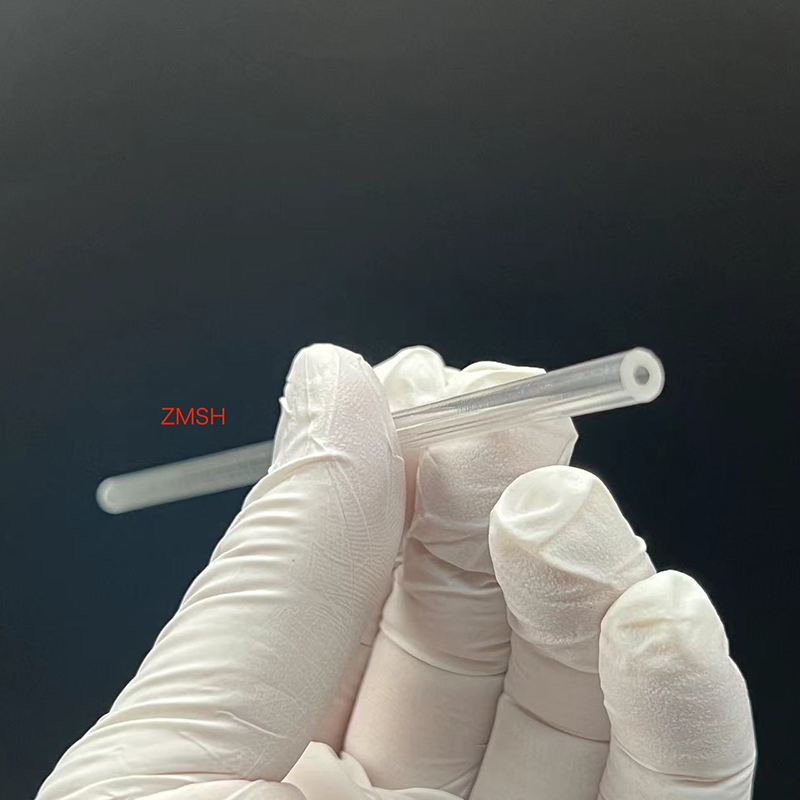

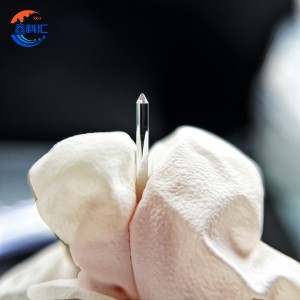

Sapphire Rod Cylinder Conical End Rod Tapered Rods

Detailed Diagram

Product Introduction of Sapphire Rod

Sapphire rods conical are precision-shaped single crystal components made from high-purity sapphire (Al₂O₃), engineered into a tapered cylindrical form. Due to sapphire’s unique combination of extreme hardness (9 on the Mohs scale), high melting point (2030°C), excellent optical transparency from the ultraviolet to the mid-infrared range (200 nm–5.5 μm), and outstanding resistance to wear, pressure, and chemical corrosion, these conical sapphire rods are widely used in advanced optical, industrial, and scientific applications.

The conical geometry is particularly suitable for laser focusing, optical beam guidance, or as mechanical probing components under extreme environments. conical Sapphire rods are valued not only for their mechanical durability but also for their optical performance and ability to retain structural integrity in high-pressure and high-temperature environments.

These sapphire rods are commonly used in industries such as aerospace, medical instruments, semiconductor processing, metrology, and high-energy physics.

Manufacturing Principle of Sapphire Rod

Conical Sapphire rods are manufactured through a multi-stage process that involves:

-

Crystal Growth

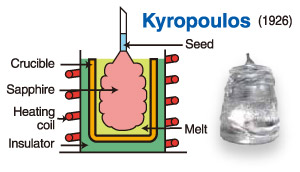

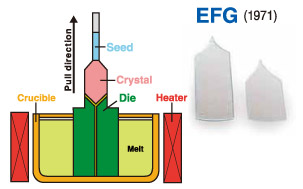

The base material is a high-quality single-crystal sapphire grown using either the Kyropoulos (KY) method or the Edge-defined Film-fed Growth (EFG) technique. These methods allow the production of large, stress-free, and optically pure sapphire crystals for sapphire rod. -

Precision Machining

After crystal growth, cylindrical blanks are machined into conical shapes using ultra-precision CNC machining tools. Special attention is paid to taper angle accuracy, surface concentricity, and dimensional tolerances. -

Polishing and Surface Treatment

The machined conical sapphire rods undergo multiple polishing stages to achieve optical-grade surface finishes. This includes chemical-mechanical polishing (CMP) to ensure low surface roughness and maximum light transmission. -

Quality Inspection

Final products are subjected to interferometric surface inspection, optical transmission tests, and dimensional verification to meet strict industrial or scientific standards.

Applications of Sapphire Rods

Conical Sapphire rods are highly versatile and are applied in a wide variety of high-demand technical fields:

-

Laser Optics By Sapphire Rod

Used as beam focusing tips, output windows, or collimating lenses in high-power laser systems due to their excellent thermal and optical stability. -

Medical Devices By Sapphire Rod

Applied in endoscopic or laparoscopic instruments as probes or viewing windows, where miniaturization, biocompatibility, and durability are essential. -

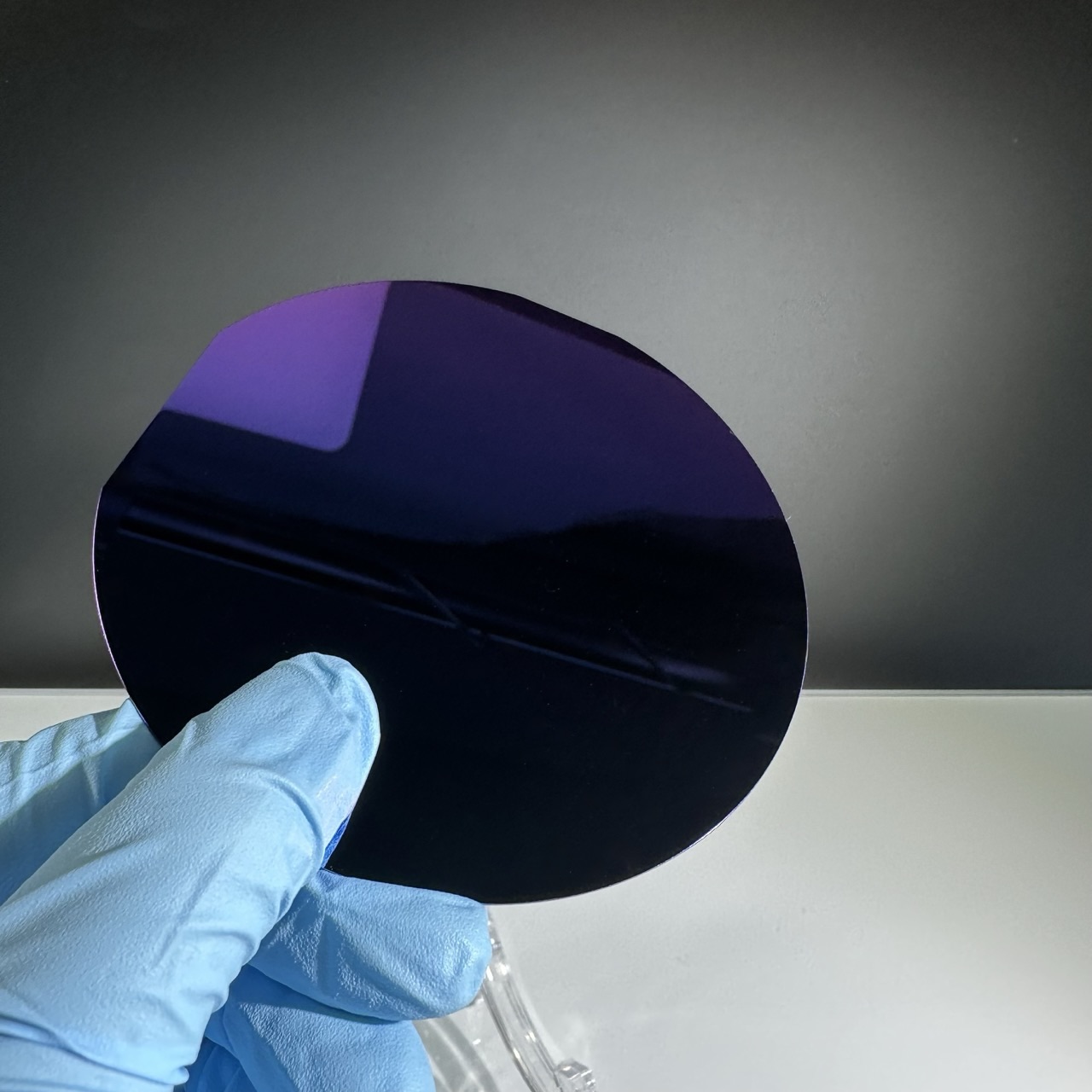

Semiconductor Equipment By Sapphire Rod

Employed as inspection or alignment tools, especially in plasma etching or deposition chambers, due to their resistance to ion bombardment and chemicals. -

Aerospace and Defense By Sapphire Rod

Utilized in missile guidance systems, sensor shields, or heat-resistant mechanical parts in extreme environments. -

Scientific Instrumentation By Sapphire Rod

Applied in high-temperature or high-pressure experimental setups as viewports, pressure sensors, or thermal probes.

Key Advantages of Sapphire Rods

-

Outstanding Mechanical Properties (sapphire rod)

Second only to diamond in hardness, sapphire is extremely resistant to scratching, deformation, and wear. -

Wide Optical Transmission Range (sapphire rod)

Transparent in UV, visible, and IR spectra, making it ideal for multispectral optical systems. -

High Thermal Resistance(sapphire rod)

Withstands operating temperatures above 1600°C and has a melting point exceeding 2000°C. -

Chemical Inertness (sapphire rod)

Unaffected by most acids and alkalis, making it ideal for corrosive environments such as chemical vapor deposition (CVD) reactors or plasma chambers. -

Customizable Geometry (sapphire rod)

Available in a wide range of taper angles, lengths, and diameters. Double-ended, stepped, or convex profiles are also possible.

Frequently Asked Questions (FAQ) of Sapphire Rods

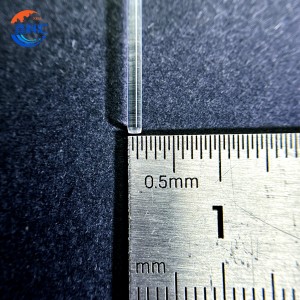

Q1: What taper angles are available for sapphire conical rods?

A: Taper angles can be customized from as low as 5° to over 60°, depending on the intended optical or mechanical function.

Q2: Are anti-reflective coatings available?

A: Yes. Although sapphire itself has good transmission, AR coatings for specific wavelengths (e.g., 1064 nm, 532 nm) can be applied upon request.

Q3: Can sapphire conical rods be used under vacuum or in plasma environments?

A: Absolutely. Sapphire is one of the best materials for ultra-high vacuum and reactive plasma conditions due to its inertness and outgassing-free nature.

Q4: What are the standard tolerances for diameter and length?

A: Typical tolerances are ±0.05 mm for diameter and ±0.1 mm for length. Stricter tolerances can be achieved for high-precision applications.

Q5: Can you supply prototypes or small quantities?

A: Yes. We support low-volume orders, R&D samples, and full-scale production with consistent quality control.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.