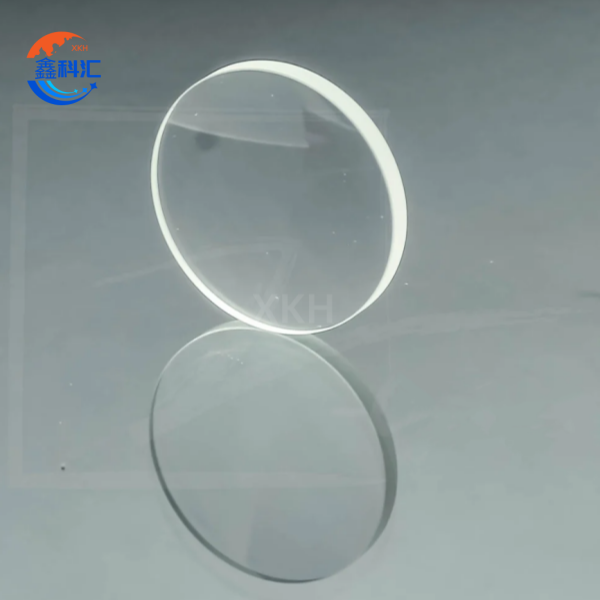

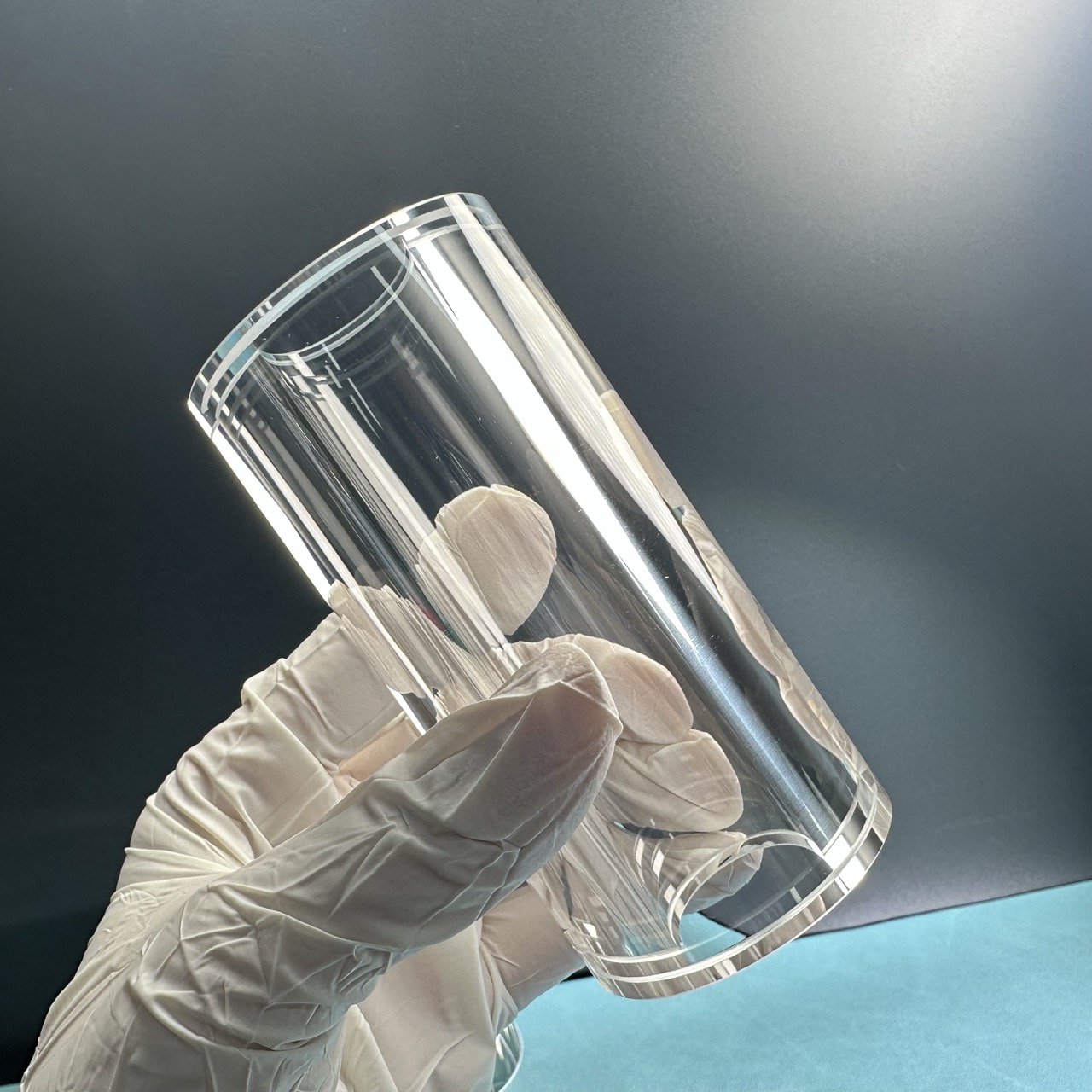

Sapphire Optical Windows Single Crystal Al₂O₃ Wear-resisting Customized

Technical specification

| Parameter | Specifications |

| Material | High-purity synthetic sapphire (Al₂O₃), <5 ppm impurities |

| Diameter Range | 1–300 mm (custom sizes available) |

| Thickness Tolerance | ±0.05 mm (standard), ±0.01 mm (precision grade) |

| Surface Quality | 20/10 to 60/40 scratch-dig (MIL-O-13830A) |

| Flatness | λ/4 @ 633 nm (standard), λ/8 @ 10.6 μm (laser-grade) |

| Clear Aperture | >90% of diameter |

| Coating Options | Broadband anti-reflective (200–4000 nm), DLC, bandpass filters |

| Operating Temp | -200°C to 2053°C (melting point) |

Core Advantages

-

- 1.Defense & Aerospace

· Hypersonic Vehicles: Withstand thermal shocks during re-entry, maintaining optical integrity at 2000°C.

· Satellite Imaging: Deployed in high-resolution Earth observation systems (e.g., hyperspectral sensors).2.Industrial & Energy

· Plasma Chambers: Resist erosion in semiconductor etching (plasma-enhanced CVD) and fusion reactors.

· Hydrocarbon Exploration: Monitor pipeline integrity via high-pressure, corrosion-resistant windows.

3.Scientific Research

· Synchrotron Radiation: Minimize X-ray absorption (<5 ppm impurities) in beamlines.

· Quantum Computing: Enable low-loss photon transmission in cryogenic systems.

4.Commercial Innovations

· Autonomous Vehicles: LiDAR windows with DLC coatings for fog resistance and scratch immunity.

· Wearables: Ultra-thin (<1 mm) sapphire lenses for augmented reality displays.

- 1.Defense & Aerospace

XKH Custom Solutions

Our end-to-end platform delivers tailored sapphire optical components:

1.Design & Prototyping

· CAD Integration: Convert STEP/IGES files to functional prototypes within 5 business days.

· DFM Optimization: Reduce production risks via stress analysis and tolerance simulations.

2.Precision Manufacturing

· Metrology: 4D phase-shifting interferometry for λ/50 surface accuracy.

· Coating Systems: Multi-layer AR/DLC stacks tuned for specific wavelengths (e.g., 1550 nm telecom).

3.Quality Assurance

· Material Tracing: Full-chain documentation from boule growth to final inspection.

· Environmental Testing: Salt spray (MIL-STD-810G), thermal cycling (-196°C to 800°C), and vibration resistance.

4.Value-Added Services

· ESD Control: Surface resistivity customization (10⁶–10⁹ Ω) for sensitive electronics.

· Vacuum Solutions: Metallized edges with hermetic brazing for UHV systems.

Why Choose Sapphire Optical Windows?

1.Longevity: 15-year operational lifespan in space-grade applications.

2.Cost Efficiency: 30% lower material costs via optimized crystal growth.

3.Sustainability: Recyclable and RoHS/REACH compliant.

Conclusion

Sapphire optical windows redefine performance benchmarks in optoelectronics, defense, and industrial systems by synergizing material science breakthroughs with precision engineering innovations. Leveraging synthetic sapphire’s intrinsic properties—such as Mohs hardness 9, thermal stability up to 2053°C, and broad-spectrum transmittance (200nm–6μm)—these windows transcend conventional limitations, enabling transformative applications in next-generation technologies. For instance, their ability to withstand hypersonic thermal shocks (>1000°C) makes them indispensable in aerospace defense systems, while ultra-low birefringence designs ensure precision in quantum computing and gravitational wave detection.

The integration of advanced manufacturing techniques, including diamond-turning and ion-beam sputtering, allows tailored solutions for niche demands, such as spiral-shaped vacuum-compatible windows for fusion reactors or sub-100nm surface roughness for EUV lithography. Moreover, our proprietary multi-layer coatings—such as DLC-enhanced anti-reflective films—achieve >99% transmittance at critical wavelengths (e.g., 1550nm telecom), outperforming traditional materials by 30% in laser-induced damage thresholds.

As industries pivot toward miniaturization and extreme-environment reliability, sapphire optical windows are pivotal in autonomous vehicles (LiDAR fog resistance), medical robotics (autoclave-sterilizable endoscopes), and space exploration (radiation-hardened satellite payloads). By aligning material innovation with customer-centric customization, we empower global leaders to overcome technical barriers and shape the future of photonics. This commitment to excellence cements sapphire optical windows as the cornerstone of high-performance optics, driving advancements in sustainability, miniaturization, and system longevity across tomorrow’s most demanding applications.