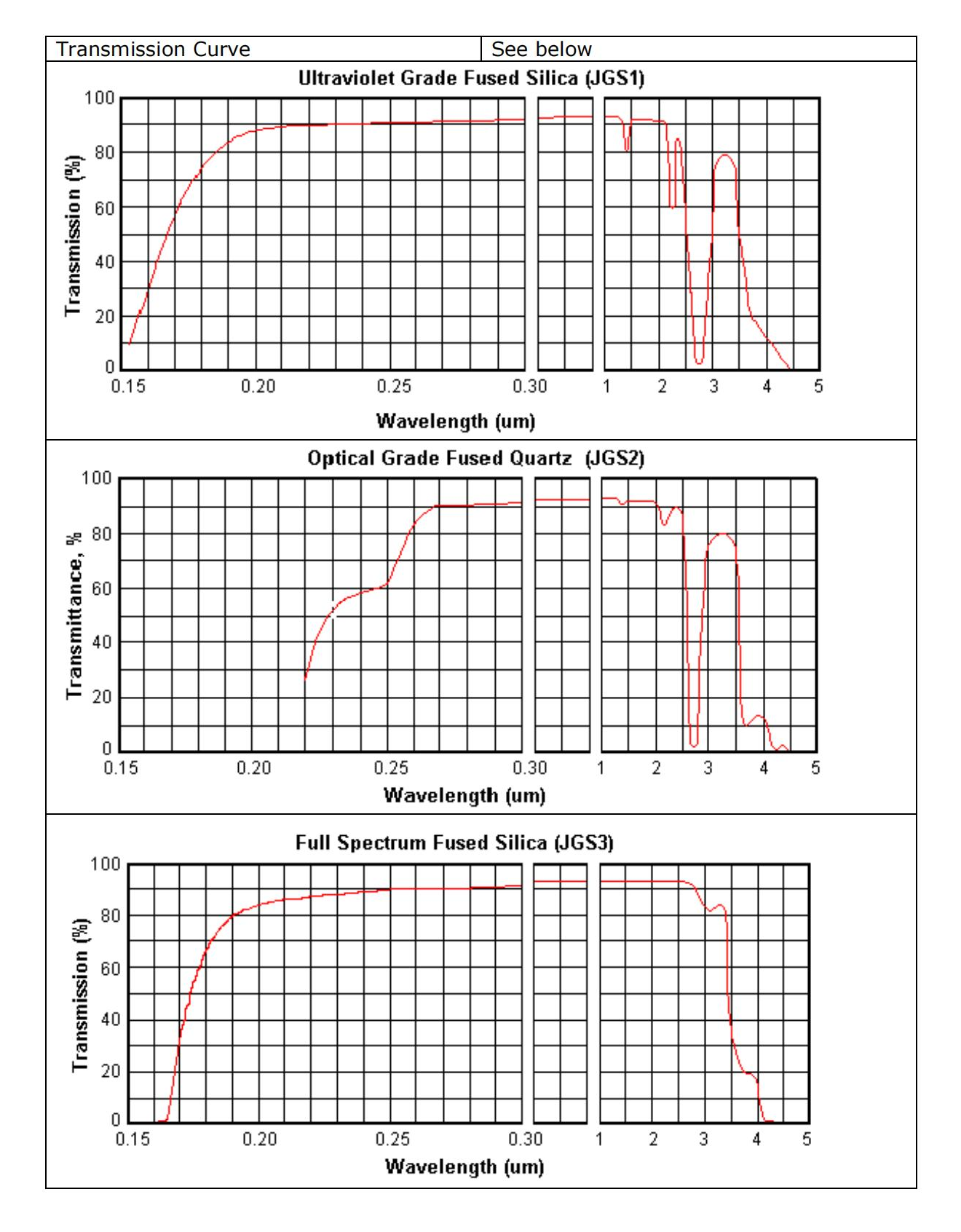

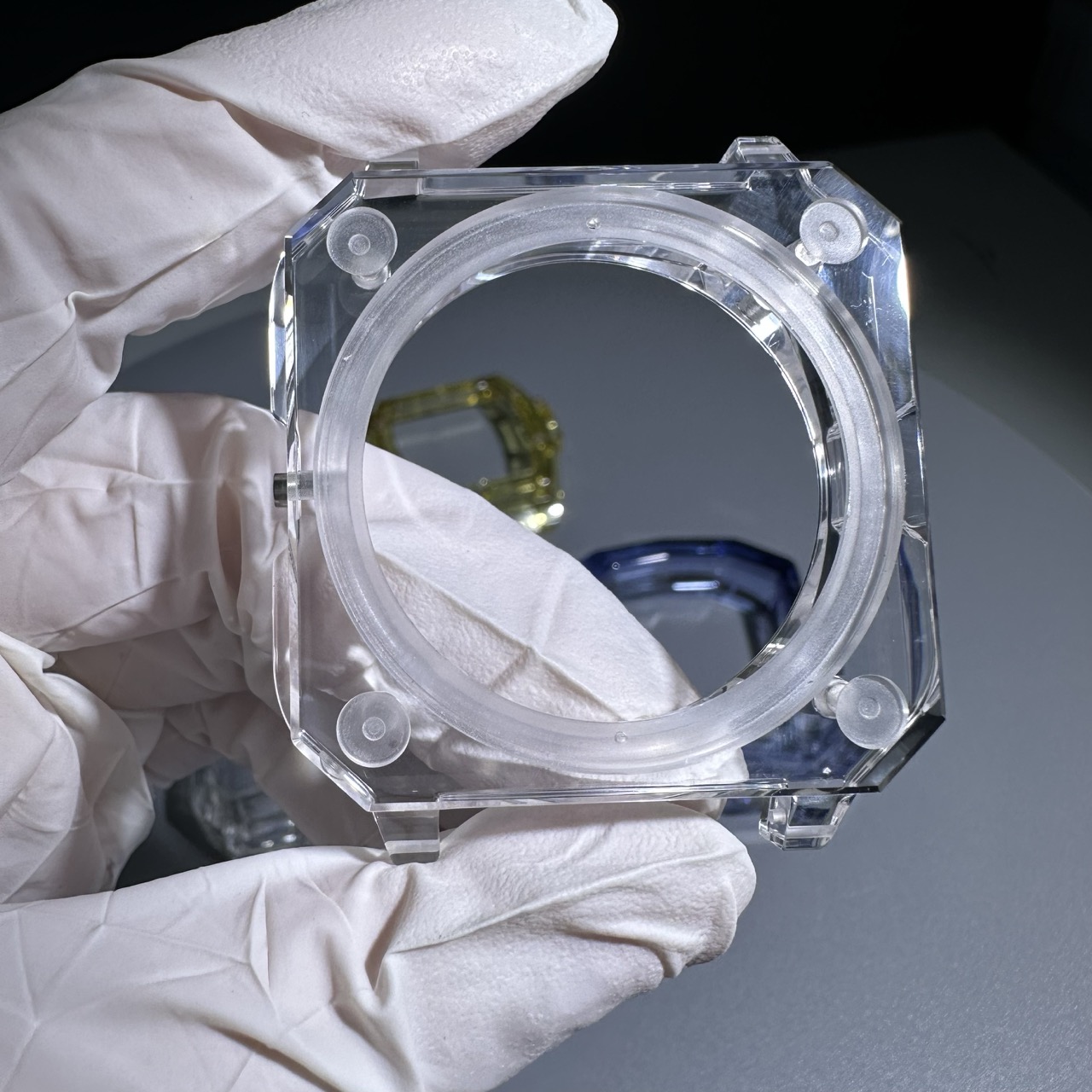

Quartz glass sheets JGS1 JGS2 JGS3

Detailed Diagram

Overview of Quartz Glass

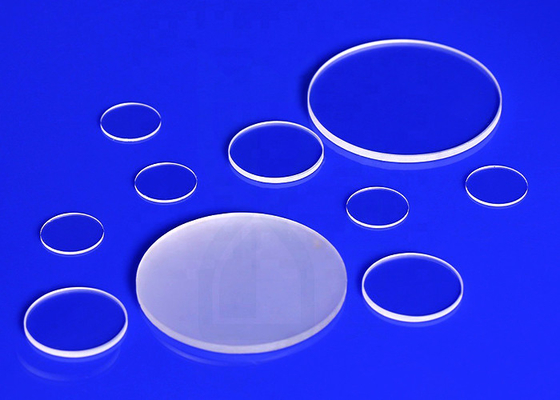

Quartz glass sheets, also known as fused silica plates or quartz plates, are highly specialized materials made from high-purity silicon dioxide (SiO₂). These transparent and durable sheets are valued for their exceptional optical clarity, thermal resistance, and chemical stability. Due to their superior properties, quartz glass sheets are widely used across multiple industries, including semiconductors, optics, photonics, solar energy, metallurgy, and advanced laboratory applications.

Our quartz glass sheets are manufactured using top-grade raw materials such as natural crystal or synthetic silica, processed through precision melting and polishing techniques. The result is an ultra-flat, low-impurity, and bubble-free surface that meets the most stringent requirements of modern industrial processes.

Key Features of Quartz Glass Sheets

-

Extreme Thermal Resistance

Quartz glass sheets can withstand temperatures up to 1100°C in continuous use and even higher in short bursts. Their extremely low coefficient of thermal expansion (~5.5 × 10⁻⁷ /°C) ensures outstanding thermal shock resistance. -

High Optical Transparency

They offer excellent transparency in the UV, visible, and IR spectrum depending on the grade, with transmission rates exceeding 90% in most visible ranges. This makes them ideal for photolithography and laser applications. -

Chemical Durability

Quartz glass is inert to most acids, bases, and corrosive gases. This resistance is crucial for cleanroom environments and high-purity chemical processing. -

Mechanical Strength and Hardness

With a Mohs hardness of 6.5–7, quartz glass sheets offer good scratch resistance and structural integrity, even under demanding conditions. -

Electrical Insulation

Quartz is an excellent electrical insulator and is widely used in high-frequency and high-voltage applications due to its low dielectric constant and high resistivity.

JGS Grade Classification

Quartz glass is often categorized by JGS1, JGS2, and JGS3 grades, commonly used in domestic and export markets:

JGS1 – UV Optical Grade Fused Silica

-

High UV transmittance (down to 185 nm)

-

Synthetic material, low impurity

-

Used in deep UV applications, UV lasers, and precision optics

JGS2 – Infrared and Visible Grade Quartz

-

Good IR and visible transmission, poor UV transmission below 260 nm

-

Lower cost than JGS1

-

Ideal for IR windows, viewing ports, and non-UV optical devices

JGS3 – General Industrial Quartz Glass

-

Includes both fused quartz and basic fused silica

-

Used in general high-temperature or chemical applications

-

Cost-effective option for non-optical needs

Mechanical Properties of Quartz Glass

| Property | Value / Range |

|---|---|

| Purity (%) | ≥99.9 |

| OH (ppm) | 200 |

| Density (g/cm³) | 2.2 |

| Vickers Hardness (MPa) | 7600~8900 |

| Young's Modulus (GPa) | 74 |

| Rigidity Modulus (GPa) | 31 |

| Poisson's Ratio | 0.17 |

| Flexural Strength (MPa) | 50 |

| Compressive Strength (MPa) | 1130 |

| Tensile Strength (MPa) | 49 |

| Torsional Strength (MPa) | 29 |

Quartz vs. Other Transparent Materials

| Property | Quartz Glass | Borosilicate Glass | Sapphire | Standard Glass |

|---|---|---|---|---|

| Max Operating Temp | ~1100°C | ~500°C | ~2000°C | ~200°C |

| UV Transmission | Excellent (JGS1) | Poor | Good | Very poor |

| Chemical Resistance | Excellent | Moderate | Excellent | Poor |

| Purity | Extremely high | Low to moderate | High | Low |

| Thermal Expansion | Very low | Moderate | Low | High |

| Cost | Moderate to high | Low | High | Very low |

FAQ of Quartz Glasses

Q1: What is the difference between fused quartz and fused silica?

A: Fused quartz is produced from natural quartz crystal melted at high temperature, while fused silica is synthesized from high-purity silicon compounds through chemical vapor deposition or hydrolysis. Fused silica typically has higher purity, better UV transmission, and lower impurity content than fused quartz.

Q2: Can quartz glass sheets withstand high temperatures?

A: Yes. Quartz glass sheets have excellent thermal stability and can operate continuously at temperatures up to 1100°C, with short-term resistance up to 1300°C. They also have extremely low thermal expansion, making them highly resistant to thermal shock.

Q3: Are quartz glass sheets resistant to chemicals?

A: Quartz is highly resistant to most acids, including hydrochloric, nitric, and sulfuric acids, as well as organic solvents. However, it can be attacked by hydrofluoric acid and strong alkaline solutions like sodium hydroxide.

Q4: Can I cut or drill quartz glass sheets myself?

A: We do not recommend DIY machining. Quartz is brittle and hard, requiring diamond tools and professional CNC or laser equipment for cutting or drilling. Improper handling may cause cracking or surface defects.

About Us