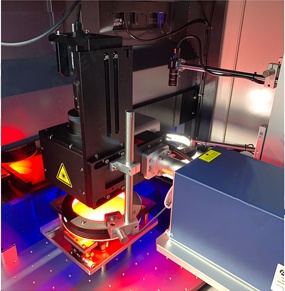

Laser Anti-Counterfeiting Marking Equipment Sapphire Wafer Marking

Technical parameters

| Parameter | Specification |

| Laser output average Power | 2500W |

| Laser Wavelength | 1060 nm |

| Laser repetition frequency | 1-1000 kHz |

| Peak Power Stability | <5% rms |

| Average Power Stability | <1% rms |

| Beam Quality | M2≤1.2 |

| Marking Area | 150mm × 150mm (Customizable) |

| Minimum Line Width | 0.01 mm |

| Marking Speed | ≤3000 mm/s |

| Visual Customization System | Professional CCD map alignment system |

| Cooling Method | Water-cooling |

| Operating Environment Temperature | 15°C to 35°C |

| Input fle formats | PLT, DXF, and other standard vector formats |

Core Principles

Laser anti-counterfeiting marking relies on the following physical/chemical effects:

1.Thermal Effects (metals/plastics): Laser heating induces oxidation, melting, or carbonization to produce contrast marks (e.g., black/gray).

2.Photochemical Effects (glass/sapphire): Short-wavelength lasers (e.g., UV 355nm) disrupt crystal lattices to form microstructural diffraction gratings, creating iridescent effects.

3.Ablation Effects (coated materials): Removal of surface layers reveals underlying colors for multi-tone contrast.

Key Technical Parameters

1.Laser Types: Fiber (1064nm), UV (355nm), Green (532nm), picosecond/femtosecond ultrashort pulses

2.Marking Precision: 10–50μm (dependent on galvanometer system)

3.Speed: 100–1000 characters/sec (varies by complexity)

Anti-Counterfeiting Mark Types

(1) Invisible/Micro Marks

Applications: High-end electronics (e.g., chips), luxury goods

Technology: UV lasers create subsurface nanostructures, visible only at specific angles or under UV light.

(2) Dynamic Color Marks

Applications: Metal watch dials, packaging

Technology: Laser-induced oxidation layers (red/blue/green) via parameter modulation (power/frequency).

(3) QR Codes/Serial Numbers

Applications: Pharmaceuticals, automotive parts

Technology: High-contrast dot-matrix engraving with database verification.

(4) Holographic Diffraction Patterns

Applications: Banknotes, ID cards

Technology: Femtosecond lasers engrave grating structures in transparent materials for dynamic optical effects.

Compatible Materials & Industries

| Material | Anti-Counterfeiting Effects | Industries |

| Metals | Oxidation colors, deep-engraved QR codes | Luxury goods, automotive, tools |

| Plastics | Carbonized black/white marks | Electronics, packaging |

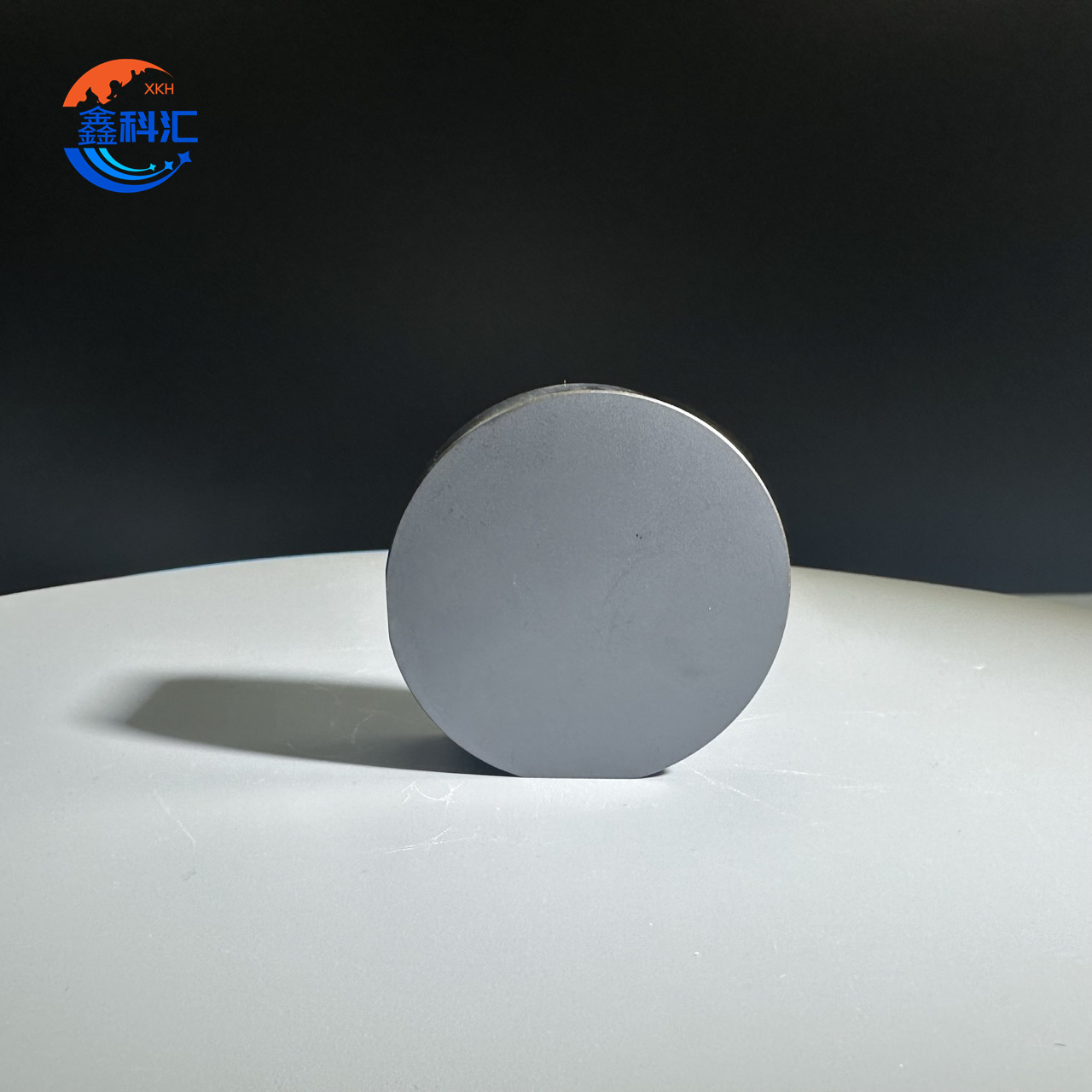

| Glass/Sapphire | Iridescent microstructures, hidden codes | Watches, phone lenses, wine bottles |

| Ceramics | Glaze modification | Premium fixtures, artwork |

| Coated Materials | Layer-selective exposure (e.g., gold-to-silver) | Credit cards, certificates |

Selection Guidelines

1.Metals/Plastics: Fiber lasers (1064nm), ≥30W power, dynamic focus capability.

2.Glass/Sapphire: UV lasers (355nm) or ultrashort pulses (ps/fs) to prevent cracking.

3.High-Precision Needs: Galvo accuracy ≤±1μm with CCD vision alignment.

Critical Notes:

· Ultra-hard materials (e.g., sapphire) require parameter testing to avoid thermal cracks.

· Color marking necessitates pre-trials for stability (e.g., metal oxidation hues may age).

Laser anti-counterfeiting systems enable non-contact, high-precision, programmable marking, serving as a cornerstone of modern security technology. Their efficacy hinges on controlled laser-material interactions, mandating tailored laser sources and parameters based on material properties (hardness, thermal sensitivity).

Comprehensive Solutions for Your Laser Anti-Counterfeiting Needs

At XKH, we specialize in delivering cutting-edge Laser Anti-Counterfeiting Marking Systems tailored to your industry’s security and branding requirements. Our advanced laser technology ensures high-precision, permanent, and tamper-proof markings on a wide range of materials, including metals, plastics, glass, and ceramics—ideal for applications in luxury goods, electronics, automotive, pharmaceuticals, and secure packaging.

1. Customized Solutions: We analyze your specific needs—whether it’s invisible micro-codes, dynamic color marks, or high-security QR patterns—and recommend the optimal laser system (fiber, UV, or ultrafast lasers).

2. End-to-End Support: From initial consultation and sample testing to on-site installation and operator training, we ensure seamless integration into your production line.

3. Reliable After-Sales Service: Enjoy lifetime technical support, preventive maintenance, and rapid spare-part supply to maximize uptime.

4. Future-Ready Upgrades: As your needs evolve, our modular systems allow for easy upgrades (e.g., higher precision, faster speeds, or new marking techniques).

Your Trusted Partner in Anti-Counterfeiting Innovation

We don’t just sell equipment—we deliver trust, security, and long-term value. Contact us today for a free feasibility assessment and discover how our laser solutions can protect your brand and enhance product authenticity.