JGS1, JGS2, and JGS3 Fused Silica Optical Glass

Detailed Diagram

Overview of JGS1, JGS2, and JGS3 Fused Silica

JGS1, JGS2, and JGS3 are three precision-engineered grades of fused silica, each designed for specific regions of the optical spectrum. Produced from ultra-high purity silica through advanced melting processes, these materials exhibit exceptional optical clarity, low thermal expansion, and outstanding chemical stability.

-

JGS1 – UV-grade fused silica optimized for deep ultraviolet transmission.

-

JGS2 – Optical-grade fused silica for visible to near-infrared applications.

-

JGS3 – IR-grade fused silica with enhanced infrared performance.

By selecting the right grade, engineers can achieve optimal transmission, durability, and stability for demanding optical systems.

Grade of JGS1, JGS2, and JGS3

JGS1 Fused Silica – UV Grade

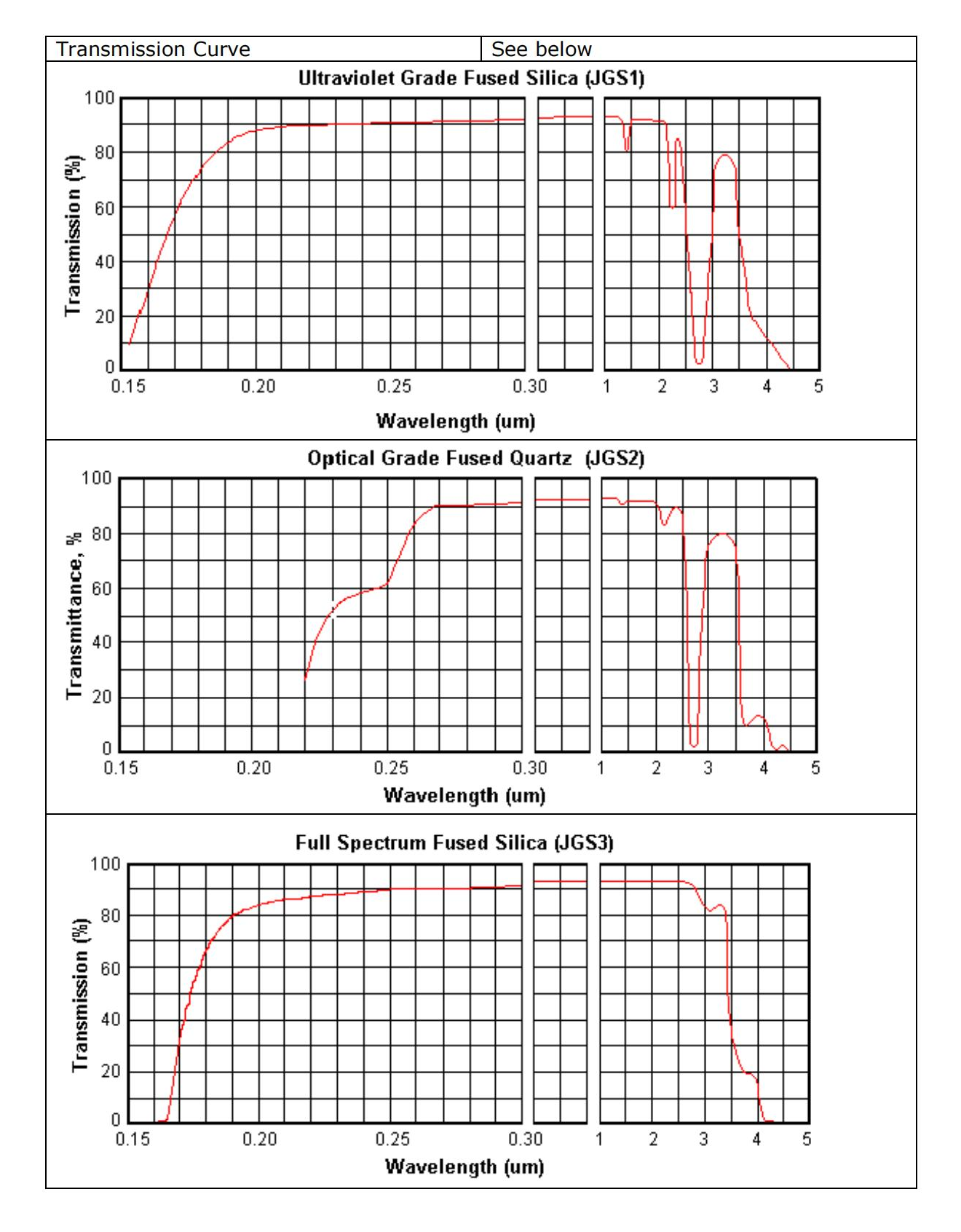

Transmission Range: 185–2500 nm

Main Strength: Superior transparency in deep UV wavelengths.

JGS1 fused silica is produced using synthetic high-purity silica with carefully controlled impurity levels. It delivers exceptional performance in UV systems, offering high transmittance below 250 nm, very low autofluorescence, and strong resistance to solarization.

Performance Highlights of JGS1:

-

Transmission >90% from 200 nm to the visible range.

-

Low hydroxyl (OH) content to minimize UV absorption.

-

High laser damage threshold suitable for excimer lasers.

-

Minimal fluorescence for accurate UV measurement.

Common Applications:

-

Photolithography projection optics.

-

Excimer laser windows and lenses (193 nm, 248 nm).

-

UV spectrometers and scientific instrumentation.

-

High-precision metrology for UV inspection.

JGS2 Fused Silica – Optical Grade

Transmission Range: 220–3500 nm

Main Strength: Balanced optical performance from visible to near-infrared.

JGS2 is designed for general-purpose optical systems where visible light and NIR performance are key. While it provides moderate UV transmission, its primary value lies in its optical uniformity, low wavefront distortion, and excellent thermal resistance.

Performance Highlights of JGS2:

-

High transmittance across VIS–NIR spectrum.

-

UV capability down to ~220 nm for flexible applications.

-

Excellent resistance to thermal shock and mechanical stress.

-

Uniform refractive index with minimal birefringence.

Common Applications:

-

Precision imaging optics.

-

Laser windows for visible and NIR wavelengths.

-

Beam splitters, filters, and prisms.

-

Optical components for microscopy and projection systems.

JGS3 Fused Silica – IR

Grade

Transmission Range: 260–3500 nm

Main Strength: Optimized infrared transmission with low OH absorption.

JGS3 fused silica is engineered to provide maximum infrared transparency by reducing hydroxyl content during production. This minimizes the absorption peaks at ~2.73 μm and ~4.27 μm, which can degrade performance in IR applications.

Performance Highlights of JGS3:

-

Superior IR transmission compared to JGS1 and JGS2.

-

Minimal OH-related absorption losses.

-

Excellent thermal cycling resistance.

-

Long-term stability in high-temperature environments.

Common Applications:

-

IR spectroscopy cuvettes and windows.

-

Thermal imaging and sensor optics.

-

IR protective covers in harsh environments.

-

Industrial viewing ports for high-temperature processes.

Key Comparative Data of JGS1, JGS2, and JGS3

| Item | JGS1 | JGS2 | JGS3 |

| Maximum Size | <Φ200mm | <Φ300mm | <Φ200mm |

| Transmission Range (Medium transmission ratio) | 0.17~2.10um (Tavg>90%) | 0.26~2.10um (Tavg>85%) | 0.185~3.50um (Tavg>85%) |

| OH- Content | 1200 ppm | 150 ppm | 5 ppm |

| Fluorescence (ex 254nm) | Virtually Free | Strong v-b | Strong V-B |

| Impurity Content | 5 ppm | 20-40 ppm | 40-50 ppm |

| Birefringence Constant | 2-4 nm/cm | 4-6 nm/cm | 4-10 nm/cm |

| Melting Method | Synthetic CVD | Oxy-hydrogen melting | Electrical melting |

| Applications | Laser substrate: Window, lens, prism, mirror... | Semiconductor and high temperature window | IR & UV substrate |

FAQ – JGS1, JGS2, and JGS3 Fused Silica

Q1: What are the main differences between JGS1, JGS2, and JGS3?

A:

-

JGS1 – UV-grade fused silica with outstanding transmission from 185 nm, ideal for deep-UV optics and excimer lasers.

-

JGS2 – Optical-grade fused silica for visible to near-infrared (220–3500 nm) applications, suitable for general-purpose optics.

-

JGS3 – IR-grade fused silica optimized for infrared (260–3500 nm) with reduced OH absorption peaks.

Q2: Which grade should I choose for my application?

A:

-

Choose JGS1 for UV lithography, UV spectroscopy, or 193 nm/248 nm laser systems.

-

Choose JGS2 for visible/NIR imaging, laser optics, and measurement devices.

-

Choose JGS3 for IR spectroscopy, thermal imaging, or high-temperature viewing windows.

Q3: Do all JGS grades have the same physical strength?

A: Yes. JGS1, JGS2, and JGS3 share the same mechanical properties—density, hardness, and thermal expansion—because they are all made from high-purity fused silica. The main differences are optical.

Q4: Are JGS1, JGS2, and JGS3 resistant to laser damage?

A: Yes. All grades have a high laser damage threshold (>20 J/cm² at 1064 nm, 10 ns pulses). For UV lasers, JGS1 offers the highest resistance to solarization and surface degradation.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.