High-Precision Single-Side Polishing Equipment

Video of Single-Side Polishing Equipment

Introduce of Single-Side Polishing Equipment

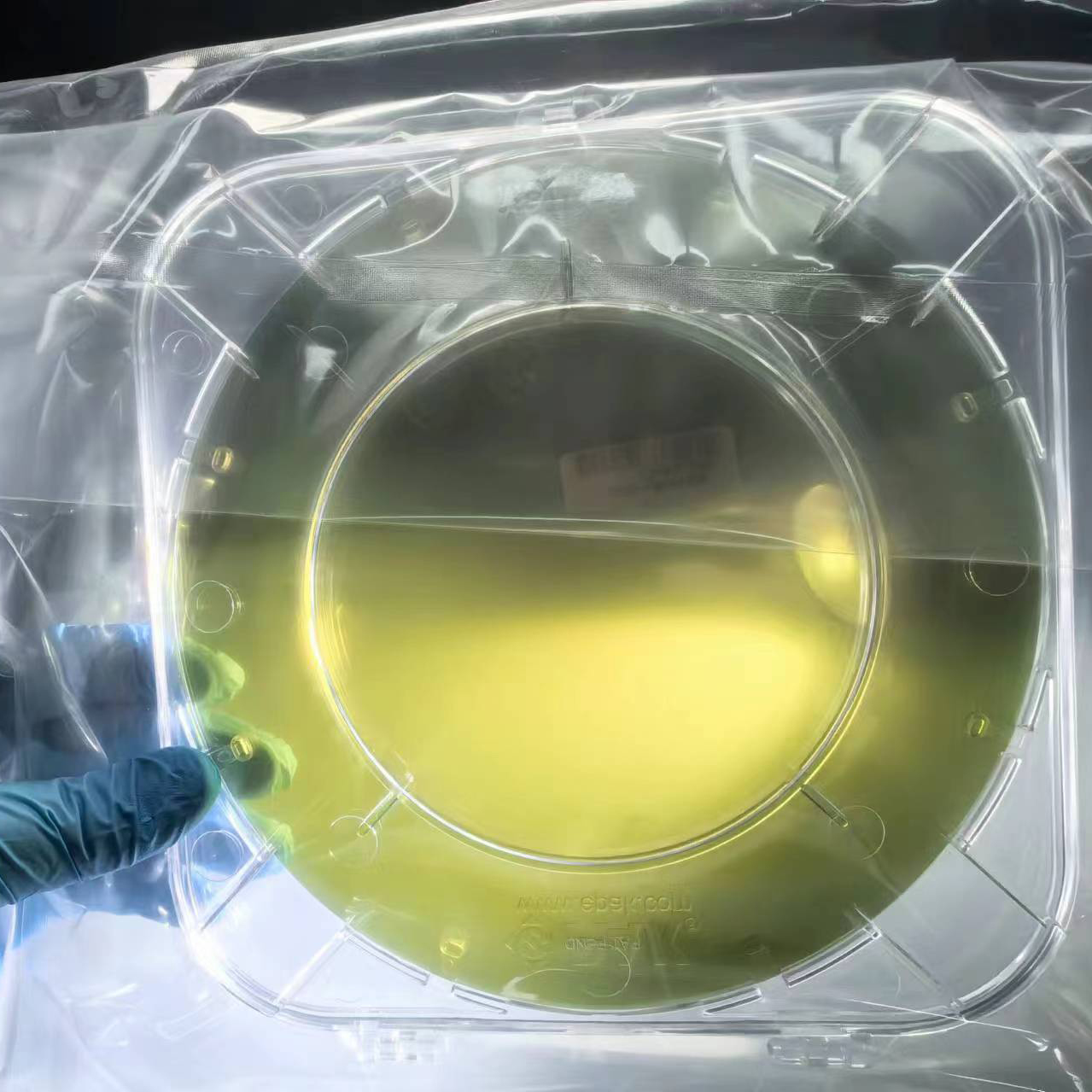

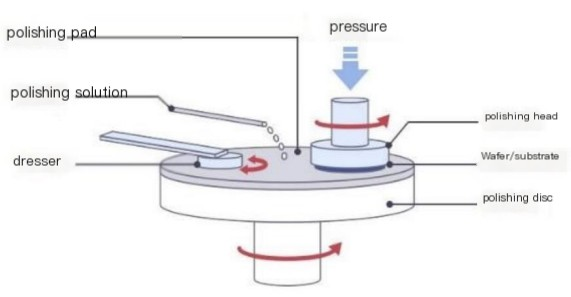

The single-side polishing machine is a highly specialized piece of equipment designed for the precision finishing of hard and brittle materials. With the rapid development of the semiconductor industry, optoelectronics, optical components, and advanced material applications, the demand for high-precision and high-efficiency polishing equipment has become increasingly urgent. The single-side polishing machine utilizes the relative motion between the polishing disc and the ceramic plates to generate uniform pressure on the workpiece surface, enabling excellent planarization and mirror-like finishing.

Unlike traditional double-side polishing machines, the single-side polishing machine offers greater flexibility in handling different sizes and thicknesses of wafers or substrates. This makes it particularly suitable for processing materials such as silicon wafers, silicon carbide, sapphire, gallium arsenide, germanium flakes, lithium niobate, lithium tantalate, and optical glass. The precision achieved with this type of equipment ensures that the processed components meet the strict requirements of microelectronics, LED substrates, and high-performance optics.

Advantage of Single-Side Polishing Equipment

The design philosophy of the single-side polishing machine emphasizes stability, precision, and efficiency. The main body of the machine is usually made of cast and forged steel, which provides strong mechanical stability and minimizes vibration during operation. High-quality international components are adopted for critical systems such as the rotation drive, power transmission, and control system, ensuring reliable performance and a long service life.

Another key advantage lies in its humanized operation interface. Modern single-side polishing machines are equipped with intelligent control panels, allowing operators to quickly adjust process parameters such as polishing speed, pressure, and rotation rate. This enables highly reproducible processing conditions, which is essential for industries where consistency is critical.

From the perspective of process versatility, the equipment can accommodate a wide range of machining sizes, typically from 50mm up to 200mm or larger, depending on the model. The rotation rate of the polishing disc generally falls between 50 to 80 rpm, while the power rating varies from 11kW to over 45kW. With such a wide spectrum of configurations, users can select a model that best fits their production requirements, whether for research-scale laboratories or for large-scale industrial production.

Furthermore, advanced models feature multiple polishing heads, synchronized by servo electronic control systems. This ensures that all polishing heads maintain consistent speed during operation, thereby improving both processing quality and yield. In addition, the cooling and temperature control systems integrated into the machine guarantee thermal stability, which is a vital factor when dealing with heat-sensitive materials.

The single-side polishing machine represents a critical piece of manufacturing equipment in the modern era of high technology. Its combination of robust mechanical design, intelligent control, multi-material compatibility, and superior surface finishing performance makes it an indispensable tool for companies and research institutes that require high-accuracy surface preparation of advanced materials.

Product Features of Single-Side Polishing Equipment

-

High Stability: The machine body is cast and forged to ensure structural rigidity and excellent operational stability.

-

Precision Components: International-grade bearings, motors, and electronic control units guarantee long service life and reliable performance.

-

Flexible Models: Available in multiple series (305, 36D, 50D, 59D, and X62 S59D-S) to meet diverse production requirements.

-

Humanized Interface: Easy-to-use operation panel with digital settings for polishing parameters, enabling quick recipe adjustments.

-

Efficient Cooling: Integrated water-cooled systems with precision temperature sensors to maintain stable polishing conditions.

-

Multi-Head Synchronization: Servo electronic control ensures synchronized speed of multiple polishing heads for consistent results.

Technical Specifications of Single-Side Polishing Equipment

| Category | Item | 305 Series | 36D Series | 50D Series | 59D Series |

|---|---|---|---|---|---|

| Polishing Disc | Diameter | 820 mm | 914 mm | 1282 mm | 1504 mm |

| Ceramic Plates | Diameter | 305 mm | 360 mm | 485 mm | 576 mm |

| Optimum Machining | Workpiece Size | 50–100 mm | 50–150 mm | 150–200 mm | 200 mm |

| Power | Main Motor | 11 kW | 11 kW | 18.5 kW | 30 kW |

| Rotation Rate | Polishing Disc | 80 rpm | 65 rpm | 65 rpm | 50 rpm |

| Dimensions (L×W×H) | — | 1920×1125×1680 mm | 1360×1330×2799 mm | 2334×1780×2759 mm | 1900×1900×2700 mm |

| Machine Weight | — | 2000 kg | 3500 kg | 7500 kg | 11826 kg |

| Item | Parameter | Material |

|---|---|---|

| Diameter of Main Polishing Disc | Φ1504 × 40 mm | SUS410 |

| Diameter of Polishing Disc (Head) | Φ576 × 20 mm | SUS316 |

| Max Speed of Main Polishing Disc | 60 rpm | — |

| Max Speed of Upper Throwing Head | 60 rpm | — |

| Number of Polishing Heads | 4 | — |

| Dimensions (L×W×H) | 2350 × 2250 × 3050 mm | — |

| Equipment Weight | 12 t | — |

| Max Pressure Range | 50–500 ± kg | — |

| Total Power of Whole Machine | 45 kW | — |

| Loading Capacity (per head) | 8 h/φ 150 mm (6”) or 5 h/φ 200 mm (8”) | — |

Application Range of Single-Side Polishing Equipment

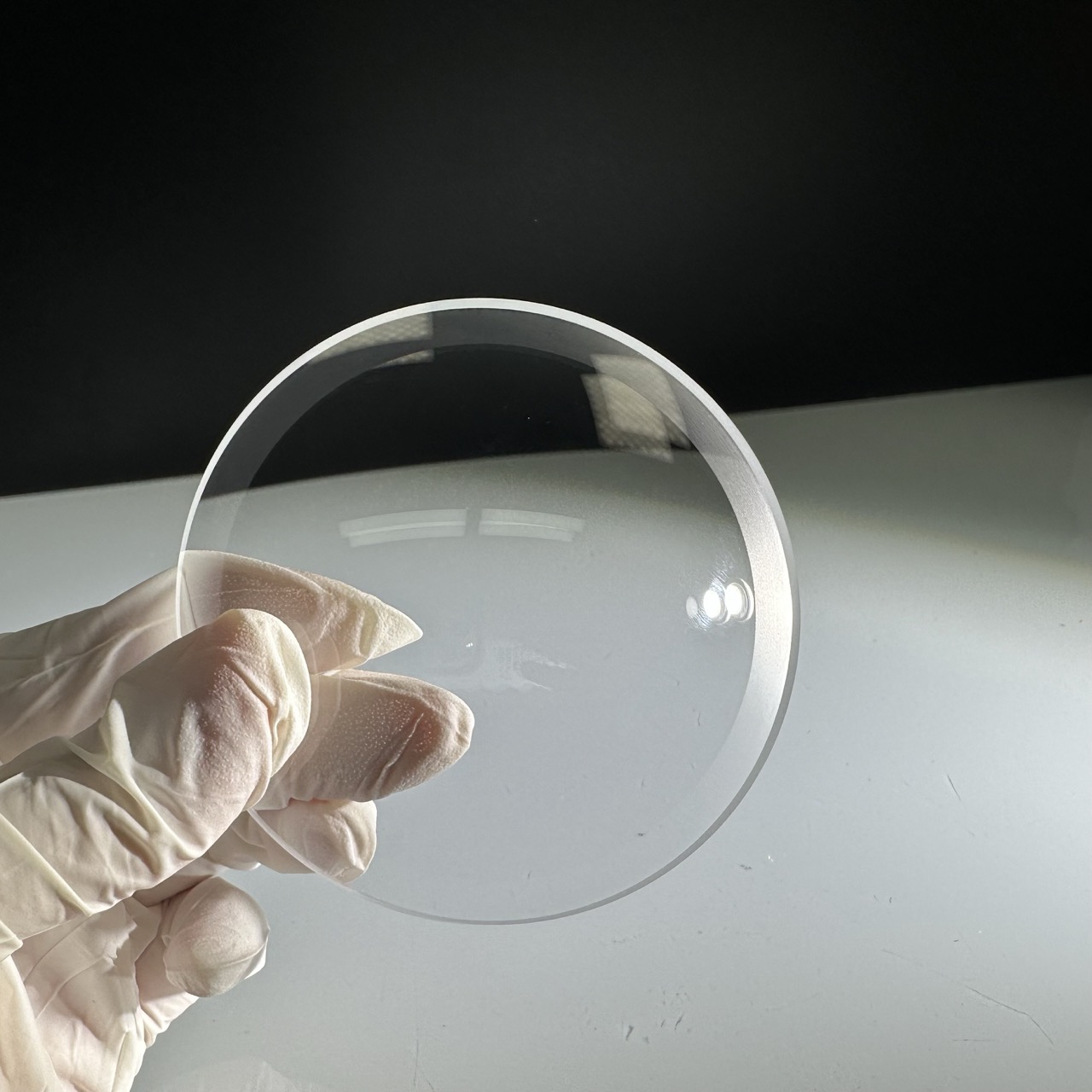

The machine is designed for single-side polishing of a wide variety of hard and brittle materials, including:

-

Silicon wafers for semiconductor devices

-

Silicon carbide for power electronics and LED substrates

-

Sapphire wafers for optoelectronics and watch crystals

-

Gallium arsenide for high-frequency electronic applications

-

Germanium flakes for infrared optics

-

Lithium niobate and lithium tantalate for piezoelectric components

-

Glass substrates for precision optics and communication devices

Frequently Asked Questions (FAQ) of Single-Side Polishing Equipment

Q1: What materials can the single-side polishing machine process?

The machine is suitable for silicon wafers, sapphire, silicon carbide, gallium arsenide, glass, and other brittle materials. (Keywords: polishing machine, brittle materials)

Q2: What are the typical polishing disc sizes available?

Depending on the series, polishing discs range from 820 mm to 1504 mm in diameter. (Keywords: polishing disc, machine size)

Q3: What is the rotation rate of the polishing disc?

The rotation rate varies from 50 to 80 rpm, depending on the model. (Keywords: rotation rate, polishing speed)

Q4: How does the control system improve polishing quality?

The machine uses servo electronic control for synchronized head rotation, ensuring uniform pressure and stable results. (Keywords: control system, polishing head)

Q5: What is the weight and footprint of the machine?

Machine weights range from 2 tons to 12 tons, with footprints between 1360×1330×2799 mm and 2350×2250×3050 mm. (Keywords: machine weight, dimensions)

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.