High Precision Laser Drilling Machine laser drilling laser cutting

Key Features

Ultra-Fine Laser Spot Focusing

Utilizes beam expansion and high-transmittance focusing optics to achieve micron or submicron spot sizes, ensuring superior energy concentration and processing precision.

Intelligent Control System

Comes with an industrial PC and dedicated graphical interface software supporting multilingual operation, parameter adjustment, toolpath visualization, real-time monitoring, and error alerts.

Auto Programming Capability

Supports G-code and CAD import with automatic path generation for standardized and customized complex structures, streamlining the design-to-manufacture pipeline.

Fully Customizable Parameters

Allows customization of key parameters such as hole diameter, depth, angle, scanning speed, frequency, and pulse width for a variety of materials and thicknesses.

Minimal Heat-Affected Zone (HAZ)

Uses short or ultrashort pulse lasers (optional) to suppress thermal diffusion and prevent burn marks, cracks, or structural damage.

High-Precision XYZ Motion Stage

Equipped with XYZ precision motion modules with repeatability <±2μm, ensuring consistency and alignment accuracy in microstructuring.

Environment Adaptability

Suitable for both industrial and laboratory environments with optimal conditions of 18°C–28°C and 30%–60% humidity.

Standardized Electrical Supply

Standard 220V / 50Hz / 10A power supply, compliant with Chinese and most international electrical standards for long-term stability.

Application Areas

Diamond Wire Drawing Die Drilling

Delivers highly round, taper-adjustable micro-holes with precise diameter control, significantly improving die life and product consistency.

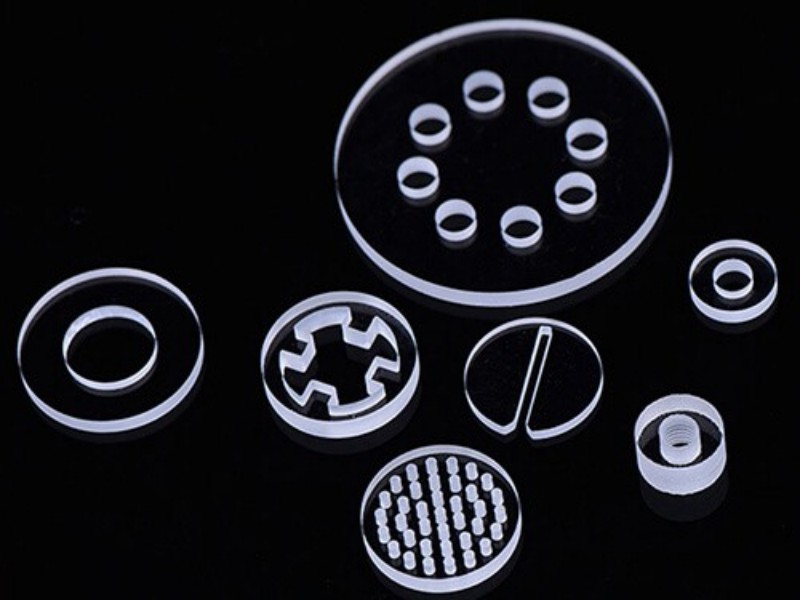

Micro-Perforation for Silencers

Processes dense and uniform micro-perforation arrays on metal or composite materials, ideal for automotive, aerospace, and energy applications.

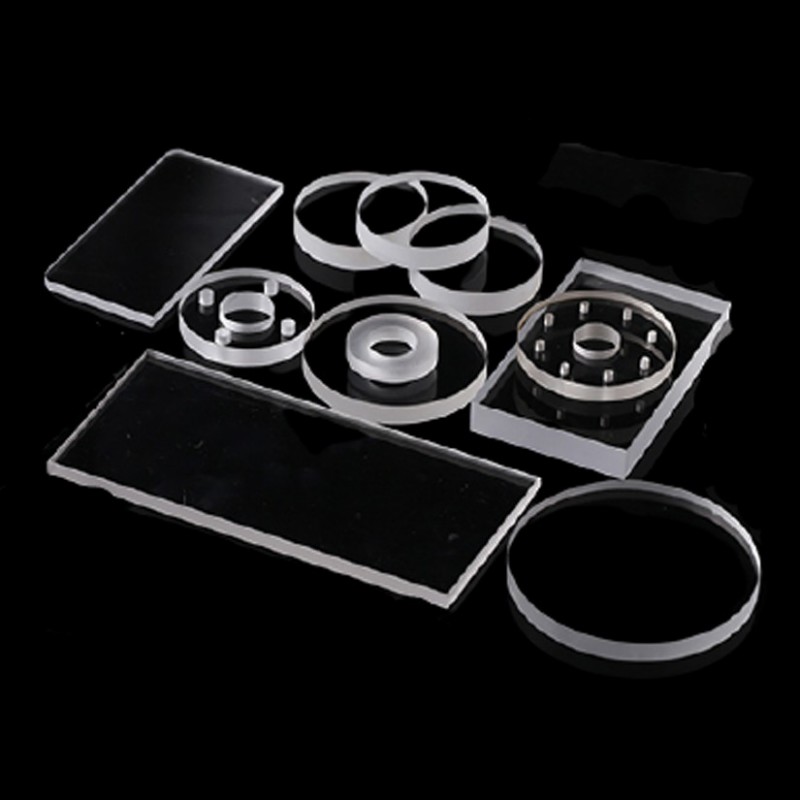

Micro-Cutting of Superhard Materials

High-energy laser beams efficiently cut PCD, sapphire, ceramics, and other hard-brittle materials with high-precision, burr-free edges.

Microfabrication for R&D

Ideal for universities and research institutes to fabricate microchannels, microneedles, and micro-optical structures with support for customized development.

Q&A

Q1: What materials can the system process?

A1: It supports processing of natural diamond, PCD, sapphire, stainless steel, ceramics, glass, and other ultra-hard or high-melting-point materials.

Q2: Does it support 3D surface drilling?

A2: Optional 5-axis module supports complex 3D surface machining, suitable for irregular parts like molds and turbine blades.

Q3: Can the laser source be replaced or customized?

A3: Supports replacement with different power or wavelength lasers, such as fiber lasers or femtosecond/picosecond lasers, configurable per your requirements.

Q4: How can I get technical support and after-sales service?

A4: We offer remote diagnostics, onsite maintenance, and spare parts replacement. All systems include full warranty and technical support packages.

Detailed Diagram