Glass Laser Drilling Machine

Features

High Precision Laser Technology

Equipped with a green laser wavelength of 532nm, this laser drilling machine offers excellent absorption in glass materials, which allows for clean, efficient drilling and cutting. The wavelength is ideal for reducing the thermal effect on glass, minimizing cracks, and maintaining structural integrity. The machine’s precision reaches up to ±0.03mm for drilling and cutting, ensuring ultra-fine and detailed processing for demanding applications.

Powerful Laser Source

The laser power of the system is at least 35W, providing sufficient energy to process glass thicknesses up to 10mm. This power level ensures stable output for continuous operation, offering rapid drilling speeds and efficient material removal while maintaining quality.

Variable Maximum Glass Size

The system is available in different configurations to accommodate various glass sizes. It supports maximum glass dimensions of 1000×600mm, 1200×1200mm, or other sizes tailored to customer requirements. This flexibility allows manufacturers to process large panels or smaller glass pieces, meeting diverse production demands.

Versatile Processing Capability

Designed to handle glass thicknesses up to 10mm, the machine is suitable for a wide range of glass types, including tempered glass, laminated glass, and specialty optical glasses. Its capability to work with different thicknesses makes it adaptable to numerous industrial needs.

Superior Drilling and Cutting Precision

The precision varies with the model, with drilling and cutting accuracies ranging from ±0.03mm to ±0.1mm. Such precision ensures consistent hole diameters and clean edges without chipping, which is critical for high-end electronics, automotive glass, and architectural applications.

User-Friendly Operation and Control

The Glass Laser Drilling Machine features an intuitive interface and advanced software control, allowing operators to program complex drilling patterns and cutting paths easily. This automation enhances productivity and reduces human error during production.

Minimal Thermal Damage and No Contact Processing

Since laser drilling is a non-contact process, it prevents mechanical stresses and contamination on the glass surface. The focused laser energy minimizes heat-affected zones, preserving the physical and optical qualities of the glass.

Robust and Stable Performance

Constructed with high-quality materials and components, the machine ensures long-term durability and stability. The robust design supports continuous industrial use with minimal maintenance requirements.

Energy Efficiency and Environmental Friendliness

The laser drilling process consumes less energy compared to traditional mechanical drilling. It produces no dust or waste, contributing to a cleaner manufacturing environment and reducing environmental impact.

Applications

Electronics and Semiconductor Industry

It is essential in manufacturing glass substrates for displays, touch screens, and semiconductor wafers, where precise micro-holes and cuts are necessary for component integration and assembly.

Automotive Glass Processing

In automotive applications, this machine processes tempered and laminated glass for windows, sunroofs, and windshields, ensuring safety standards and aesthetic quality by producing clean holes for sensors and mounting fixtures.

Architectural and Decorative Glass

The machine enables decorative cutting and precise drilling for architectural glass used in buildings and interior design. It supports complex patterns and functional perforations required for ventilation or lighting effects.

Medical and Optical Devices

For medical instruments and optical devices, high precision drilling on glass components is critical. This machine delivers the accuracy and consistency necessary for manufacturing lenses, sensors, and diagnostic equipment.

Solar Panel and Photovoltaic Industry

The laser drilling system is used to create micro-holes in glass panels for solar cells, optimizing light absorption and electrical connections without compromising panel integrity.

Consumer Electronics

Production of glass parts for smartphones, tablets, and wearable devices often requires fine drilling and cutting that this laser system efficiently provides, enabling sleek and durable product designs.

Research and Development

R&D laboratories use the Glass Laser Drilling Machine for prototype development and testing, benefitting from its high flexibility, precision, and ease of operation.

Conclusion

The Glass Laser Drilling Machine represents a significant advancement in glass processing technology. Its combination of a powerful 532nm green laser, high precision, and versatile glass size compatibility positions it as an indispensable tool for industries demanding exceptional quality and efficiency. Whether in electronics, automotive, architecture, or medical fields, this machine provides a reliable solution for drilling and cutting glass with minimal thermal impact and superior results. With user-friendly controls and robust construction, it offers a cost-effective and environmentally friendly approach to modern glass manufacturing challenges.

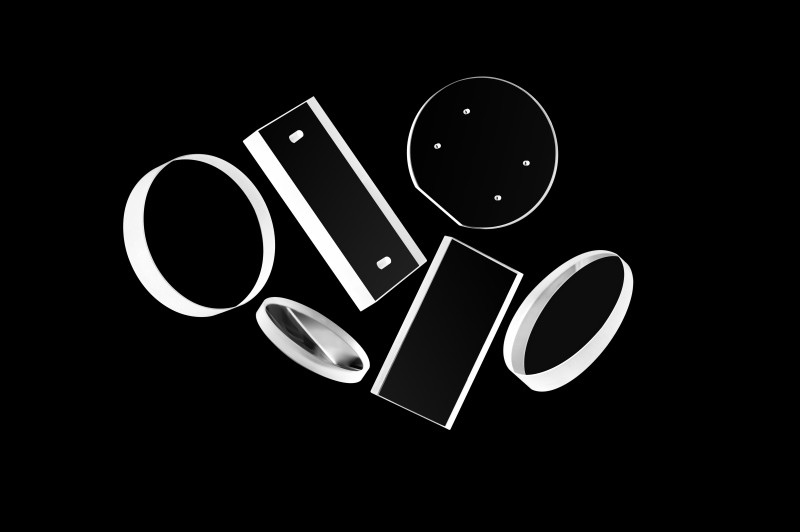

Detailed Diagram