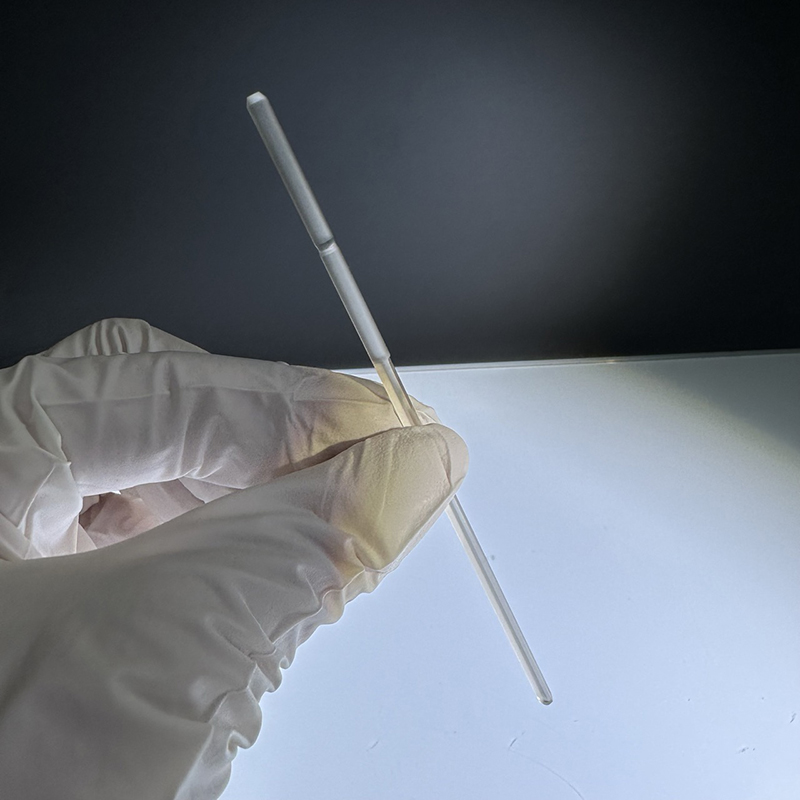

Fused Quartz Capillary Tubes

Detailed Diagram

Overview of Quartz Capillary Tubes

Fused quartz capillary tubes are precision-engineered microtubes made from high-purity amorphous silica (SiO₂). These tubes are valued for their outstanding chemical resistance, exceptional thermal stability, and superior optical clarity across a wide spectrum of wavelengths. With internal diameters ranging from a few microns to several millimeters, fused quartz capillaries are extensively used in analytical instrumentation, semiconductor manufacturing, medical diagnostics, and microfluidic systems.

Unlike ordinary glass, fused quartz offers ultra-low thermal expansion and high-temperature endurance, making it suitable for harsh environments, vacuum systems, and applications involving rapid temperature cycling. These tubes maintain dimensional integrity and chemical purity even under extreme thermal, mechanical, or chemical stress, enabling precise and repeatable performance across industries.

Manufacturing Process of Quartz Glass Sheets

-

The production of fused quartz capillary tubes requires advanced precision fabrication techniques and high-purity materials. The general manufacturing workflow includes:

-

Raw Material Preparation

High-purity quartz (typically JGS1, JGS2, JGS3, or synthetic fused silica) is selected based on application needs. These materials contain over 99.99% SiO₂ and are free of contamination like alkali metals and heavy metals. -

Melting and Drawing

Quartz rods or ingots are heated in a cleanroom environment to over 1700°C and drawn into thin tubes using micro-drawing machines. The entire process is carried out under controlled atmospheres to avoid contamination. -

Dimensional Control

Laser-based and vision-assisted feedback systems ensure accurate control of inner and outer diameters, often with tolerances as tight as ±0.005 mm. Wall thickness uniformity is also optimized during this stage. -

Annealing

After forming, tubes undergo annealing to remove internal thermal stress and improve long-term stability and mechanical strength. -

Finishing and Customization

Tubes can be flame-polished, beveled, sealed, cut to length, or cleaned depending on customer specifications. Precision end finishes are essential for fluid dynamics, optical coupling, or medical-grade applications.

-

Physical, Mechanical & Electrical Properties

| Property | Typical Value |

|---|---|

| Density | 2.2 g/cm³ |

| Compressive Strength | 1100 MPa |

| Flexural (Bending) Strength | 67 MPa |

| Tensile Strength | 48 MPa |

| Porosity | 0.14–0.17 |

| Young’s Modulus | 7200 MPa |

| Shear (Rigidity) Modulus | 31,000 MPa |

| Mohs Hardness | 5.5–6.5 |

| Short‑Term Maximum Use Temperature | 1300 °C |

| Annealing (Strain‑Relief) Point | 1280 °C |

| Softening Point | 1780 °C |

| Annealing Point | 1250 °C |

| Specific Heat (20–350 °C) | 670 J/kg·°C |

| Thermal Conductivity (at 20 °C) | 1.4 W/m·°C |

| Refractive Index | 1.4585 |

| Coefficient of Thermal Expansion | 5.5 × 10⁻⁷ cm/cm·°C |

| Hot‑Forming Temperature Range | 1750–2050 °C |

| Long‑Term Maximum Use Temperature | 1100 °C |

| Electrical Resistivity | 7 × 10⁷ Ω·cm |

| Dielectric Strength | 250–400 kV/cm |

| Dielectric Constant (εᵣ) | 3.7–3.9 |

| Dielectric Absorption Factor | < 4 × 10⁻⁴ |

| Dielectric Loss Factor | < 1 × 10⁻⁴ |

Applications

1. Biomedical and Life Sciences

-

Capillary electrophoresis

-

Microfluidic devices and lab-on-a-chip platforms

-

Blood sample collection and gas chromatography

-

DNA analysis and cell sorting

-

In vitro diagnostics (IVD) cartridges

2. Semiconductor and Electronics

-

High-purity gas sampling lines

-

Chemical delivery systems for wafer etching or cleaning

-

Photolithography and plasma systems

-

Fiber optic protection sheaths

-

UV and laser beam transmission channels

3. Analytical and Scientific Instrumentation

-

Mass spectrometry (MS) sample interfaces

-

Liquid chromatography and gas chromatography columns

-

UV-vis spectroscopy

-

Flow injection analysis (FIA) and titration systems

-

High-precision dosing and reagent dispensing

4. Industrial and Aerospace

-

High-temperature sensor sheaths

-

Capillary injectors in jet engines

-

Thermal protection in harsh industrial environments

-

Flame analysis and emissions testing

5. Optics and Photonics

-

Laser delivery systems

-

Optical fiber coatings and cores

-

Light guides and collimation systems

Customization Options

-

Length & Diameter: Fully customizable ID/OD/length combinations.

-

End Processing: Open, sealed, tapered, polished, or beveled.

-

Labeling: Laser etching, ink printing, or barcode marking.

-

OEM Packaging: Neutral or branded packaging available for distributors.

FAQ of Quartz Glasses

Q1: Can these tubes be used for biological fluids?

Yes. Fused quartz is chemically inert and biocompatible, making it ideal for applications involving blood, plasma, and other biological reagents.

Q2: What is the smallest ID you can manufacture?

We can produce inner diameters as small as 10 microns (0.01 mm), depending on the wall thickness and tube length requirements.

Q3: Are quartz capillary tubes reusable?

Yes, provided they are cleaned and handled correctly. They are resistant to most cleaning agents and autoclave cycles.

Q4: How are the tubes packaged for safe delivery?

Each tube is packaged in cleanroom-safe holders or foam trays, sealed in anti-static or vacuum-sealed bags. Bulk and protective packaging for fragile sizes is available upon request.

Q5: Do you offer technical drawings or CAD support?

Absolutely. For custom orders, we provide detailed technical drawings, tolerance specifications, and design consultation support.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.