Fused Quartz Capillary Tubes

Detailed Diagram

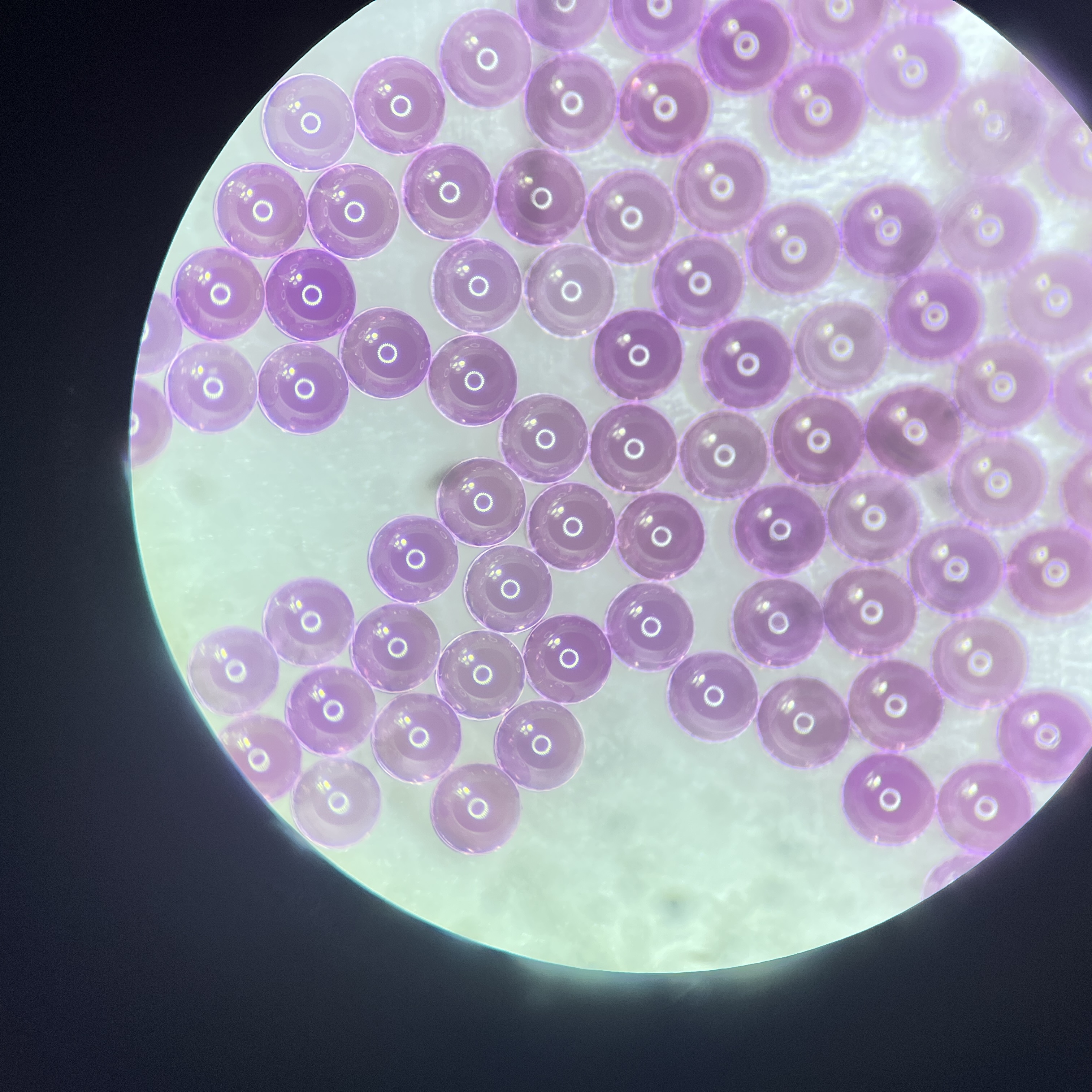

Overview of Fused Quartz Capillary Tubes

Fused Quartz Capillary Tubes are engineered from high-purity, amorphous silica through advanced fabrication techniques that yield exceptional geometric precision and unmatched material performance. These capillary tubes offer a combination of ultra-fine internal diameters, high thermal endurance, and extreme chemical stability, making them a preferred choice in industries where reliability, purity, and precision are paramount.

Whether utilized in analytical chemistry labs, microelectronics fabrication lines, or next-generation biomedical devices, our fused quartz capillaries deliver consistent performance under demanding conditions. Their non-reactive surfaces, optical transparency, and excellent dimensional tolerance make them indispensable for precision fluid transport and optical analysis.

Material Characteristics

Fused quartz is distinct from standard glass due to its high silicon dioxide content (typically >99.99%) and non-crystalline, non-porous atomic structure. This gives it a set of unique material characteristics:

-

Superior Thermal Shock Resistance: Withstands rapid temperature fluctuations without cracking or deforming.

-

Minimal Contamination Risk: No added metals or binders, ensuring purity in sensitive chemical processes.

-

Broad Optical Transmission: Excellent UV to IR light transmission, suitable for photonic and spectrometric applications.

-

Mechanical Strength: While inherently brittle, the small dimensions and uniformity improve structural integrity at micro scales.

Production Methodology

Our manufacturing process is centered around high-precision quartz drawing techniques in Class 1000 cleanroom environments. The process typically includes:

-

Preform Selection: Only the purest quartz rods or ingots are selected, screened for optical and structural integrity.

-

Micro-Drawing Technology: Specialized drawing towers produce capillaries with sub-millimeter internal diameters while preserving wall uniformity.

-

Closed-Loop Monitoring: Laser sensors and computer vision systems constantly adjust drawing parameters in real-time.

-

Post-Drawing Treatments: Tubes are cleaned in deionized water, annealed to remove thermal stress, and cut to length with high-speed diamond tools.

Performance Advantages

-

Sub-Micron Accuracy: Capable of achieving ID and OD tolerance levels below ±0.005 mm.

-

Exceptional Cleanliness: Produced in ISO-certified facilities with clean handling and packaging protocols.

-

High Operating Temperature: Continuous use temperatures up to 1100°C, with short-term exposure tolerating even higher.

-

Non-Leaching Composition: Ensures that no ionic residues are introduced into analytes or reagent streams.

-

Non-Conductive and Non-Magnetic: Ideal for sensitive electronics and electromagnetic testing environments.

Quartz vs. Other Transparent Materials

| Property | Quartz Glass | Borosilicate Glass | Sapphire | Standard Glass |

|---|---|---|---|---|

| Max Operating Temp | ~1100°C | ~500°C | ~2000°C | ~200°C |

| UV Transmission | Excellent (JGS1) | Poor | Good | Very poor |

| Chemical Resistance | Excellent | Moderate | Excellent | Poor |

| Purity | Extremely high | Low to moderate | High | Low |

| Thermal Expansion | Very low | Moderate | Low | High |

| Cost | Moderate to high | Low | High | Very low |

Applications

1. Chemical and Analytical Laboratories

Fused quartz capillary tubes are widely employed in chemical analysis where precision fluid transport is critical:

-

Gas chromatography injection systems

-

Capillary electrophoresis conduits

-

Dilution systems for high-purity reagents

3. Optical and Photonic Systems

With their clarity and ability to guide light, these tubes serve as:

-

UV or IR light pipes in sensors

-

Fiber optic connector protection

-

Laser beam collimation structures

2. Semiconductor and Photovoltaics

In ultra-clean manufacturing environments, quartz capillaries offer unmatched inertness:

-

Plasma delivery lines

-

Wafer cleaning fluid transfer

-

Monitoring and dosing of photoresist chemicals

4. Biomedical Engineering and Diagnostics

Fused quartz’s biocompatibility and small dimensions support innovations in health sciences:

-

Microneedle assemblies

-

Point-of-care diagnostic systems

-

Controlled drug delivery mechanisms

5. Aerospace and Energy

Used in systems requiring high durability in extreme environments:

-

Micro fuel injectors in aerospace engines

-

High-temperature sensors

-

Capillary-based sample systems for emission studies

-

Quartz insulation for high-vacuum applications

Frequently Asked Questions (FAQ)

Q1: Can the capillaries be sterilized?

Yes, fused quartz can withstand autoclaving, dry heat sterilization, and chemical disinfection without degradation.

Q2: Do you offer coatings or surface treatments?

We offer optional inner wall coatings such as deactivation layers, silanization, or hydrophobic treatments depending on application needs.

Q3: What’s the turnaround time for custom sizes?

Standard prototypes are shipped in 5–10 business days. Large production runs are delivered based on agreed timelines.

Q4: Can these tubes be bent into custom geometries?

Yes, under certain dimensional limits, tubes can be formed into U-shapes, spirals, or loops through controlled heating and forming.

Q5: Are quartz tubes suitable for high-pressure systems?

While fused quartz is strong, capillary tubes are typically used in low- to moderate-pressure systems. For high-pressure compatibility, reinforced designs or protective sleeves may be recommended.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.