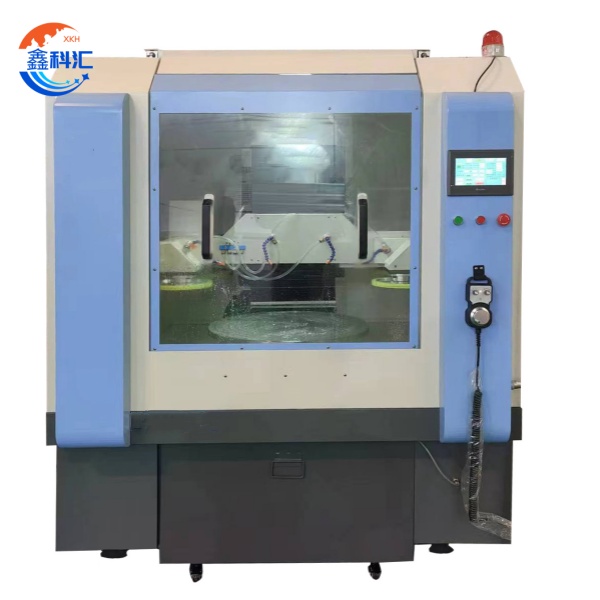

Fully Automatic Wafer Ring-Cutting Equipment Working Size 8inch/12inch Wafer Ring Cutting

Technical parameters

| Parameter | Unit | Specification |

| Maximum Workpiece Size | mm | ø12" |

| Spindle | Configuration | Single Spindle |

| Speed | 3,000–60,000 rpm | |

| Output Power | 1.8 kW (2.4 optional) at 30,000 min⁻¹ | |

| Max Blade Dia. | Ø58 mm | |

| X-Axis | Cutting Range | 310 mm |

| Y-Axis | Cutting Range | 310 mm |

| Step Increment | 0.0001 mm | |

| Positioning Accuracy | ≤0.003 mm/310 mm, ≤0.002 mm/5 mm (single error) | |

| Z-Axis | Movement Resolution | 0.00005 mm |

| Repeatability | 0.001 mm | |

| θ-Axis | Max Rotation | 380 deg |

| Spindle Type | Single spindle, equipped with rigid blade for ring cutting | |

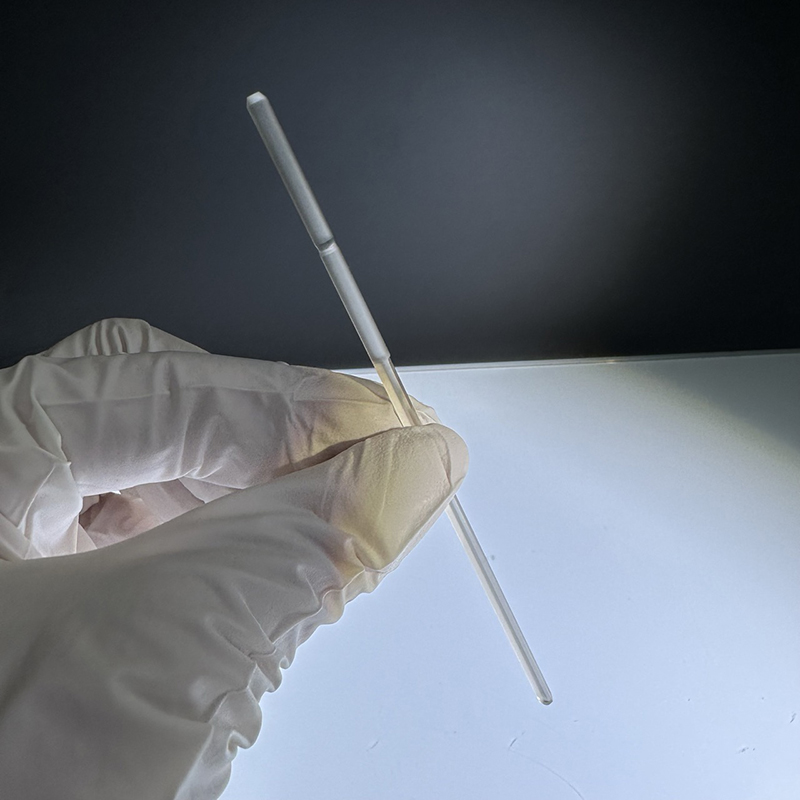

| Ring-Cutting Accuracy | μm | ±50 |

| Wafer Positioning Accuracy | μm | ±50 |

| Single-Wafer Efficiency | min/wafer | 8 |

| Multi-Wafer Efficiency | Up to 4 wafers processed simultaneously | |

| Equipment Weight | kg | ≈3,200 |

| Equipment Dimensions (W×D×H) | mm | 2,730 × 1,550 × 2,070 |

Operating Principle

The system achieves exceptional trimming performance through these core technologies:

1.Intelligent Motion Control System:

· High-precision linear motor drive (repeat positioning accuracy: ±0.5μm)

· Six-axis synchronous control supporting complex trajectory planning

· Real-time vibration suppression algorithms ensuring cutting stability

2.Advanced Detection System:

· Integrated 3D laser height sensor (accuracy: 0.1μm)

· High-resolution CCD visual positioning (5 megapixels)

· Online quality inspection module

3.Fully Automated Process:

· Automatic loading/unloading (FOUP standard interface compatible)

· Intelligent sorting system

· Closed-loop cleaning unit (cleanliness: Class 10)

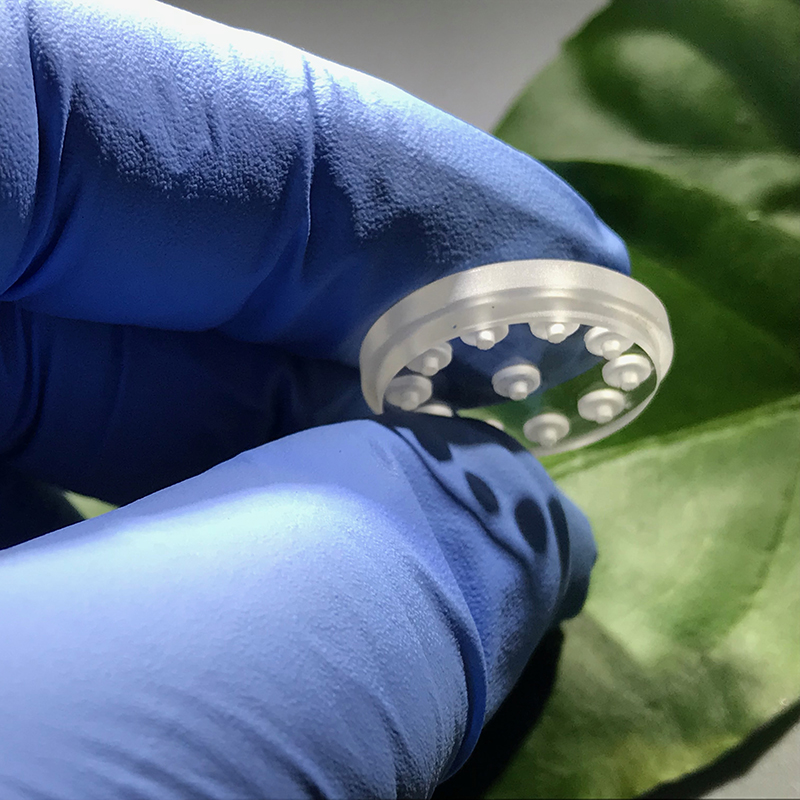

Typical Applications

This equipment delivers significant value across semiconductor manufacturing applications:

| Application Field | Process Materials | Technical Advantages |

| IC Manufacturing | 8/12" Silicon Wafers | Enhances lithography alignment |

| Power Devices | SiC/GaN Wafers | Prevents edge defects |

| MEMS Sensors | SOI Wafers | Ensures device reliability |

| RF Devices | GaAs Wafers | Improves high-frequency performance |

| Advanced Packaging | Reconstituted Wafers | Increases packaging yield |

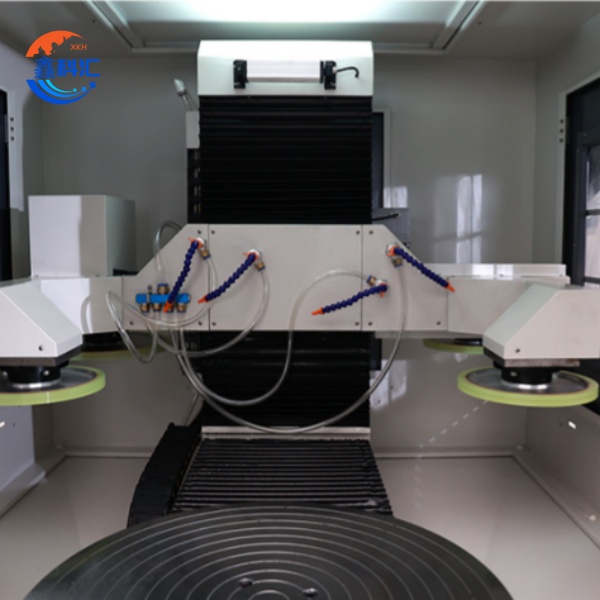

Features

1.Four-station configuration for high processing efficiency;

2.Stable TAIKO ring debonding and removal;

3.High compatibility with key consumables;

4.Multi-axis synchronous trimming technology ensures precision edge cutting;

5.Fully automated process flow significantly reduces labor costs;

6.Customized worktable design enables stable processing of special structures;

Functions

1.Ring-drop detection system;

2.Automatic worktable cleaning;

3.Intelligent UV debonding system;

4.Operation log recording;

5.Factory automation module integration;

Service Commitment

XKH provides comprehensive, full lifecycle support services designed to maximize equipment performance and operational efficiency throughout your production journey.

1. Customization Services

· Tailored Equipment Configuration: Our engineering team collaborates closely with clients to optimize system parameters (cutting speed, blade selection, etc.) based on specific material properties (Si/SiC/GaAs) and process requirements.

· Process Development Support: We offer sample processing with detailed analysis reports including edge roughness measurement and defect mapping.

· Consumables Co-Development: For novel materials (e.g., Ga₂O₃), we partner with leading consumable manufacturers to develop application-specific blades/laser optics.

2. Professional Technical Support

· Dedicated On-Site Support: Assign certified engineers for critical ramp-up phases (typically 2-4 weeks), covering:

Equipment calibration & process fine-tuning

Operator competency training

ISO Class 5 cleanroom integration guidance

· Predictive Maintenance: Quarterly health checks with vibration analysis and servo motor diagnostics to prevent unplanned downtime.

· Remote Monitoring: Real-time equipment performance tracking through our IoT platform (JCFront Connect®) with automated anomaly alerts.

3. Value-added Services

· Process Knowledge Base: Access 300+ validated cutting recipes for various materials (updated quarterly).

· Technology Roadmap Alignment: Future-proof your investment with hardware/software upgrade paths (e.g., AI-based defect detection module).

· Emergency Response: Guaranteed 4-hour remote diagnosis and 48-hour on-site intervention (global coverage).

4. Service Infrastructure

· Performance Guarantee: Contractual commitment to ≥98% equipment uptime with SLA-backed response times.

Continuous Improvement

We conduct biannual customer satisfaction surveys and implement Kaizen initiatives to enhance service delivery. Our R&D team translates field insights into equipment upgrades - 30% of firmware improvements originate from client feedback.