EFG Sapphire Tube Element Free Galerkin Method

Detailed Diagram

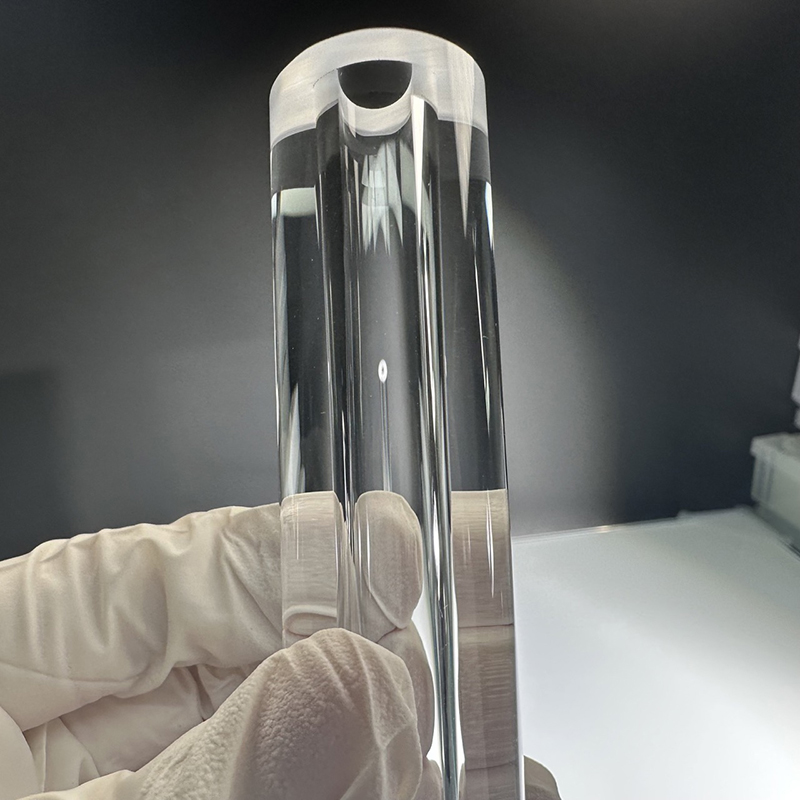

Product Overview

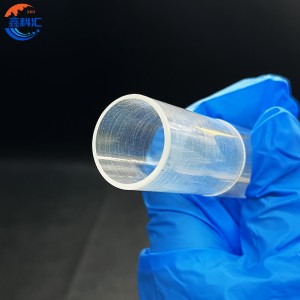

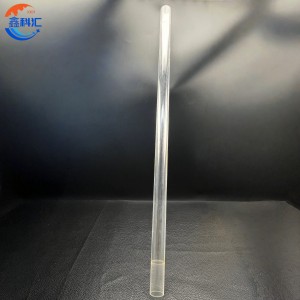

The EFG sapphire tube, manufactured by the Edge-Defined Film-Fed Growth (EFG) technique, is a single-crystal aluminum oxide (Al₂O₃) product known for its outstanding durability, purity, and optical performance. The EFG method allows sapphire tubes to be grown directly in tubular geometry, producing smooth surfaces and consistent wall thickness without extensive post-processing. These sapphire tubes demonstrate exceptional stability in high-temperature, high-pressure, and corrosive environments, making them indispensable in advanced industrial and scientific applications.

EFG Growth Technology

The EFG growth process utilizes a die or shaping tool that defines the outer and inner boundaries of the crystal as molten sapphire material is drawn upward. Through precise control of the capillary-fed melt film, the sapphire crystal solidifies into a seamless hollow cylinder.

This method ensures that the final product maintains the desired dimensions and crystallographic orientation, minimizing the need for secondary machining. Because the sapphire is formed directly in its functional shape, the EFG process offers excellent repeatability, high yield, and cost-effective scalability for large-volume production.

Performance Characteristics

-

Wide Optical Transmission: Transmits light from the ultraviolet (190 nm) to the infrared (5 µm) range, ideal for optical, analytical, and sensing applications.

-

High Structural Strength: The monocrystalline structure provides superior resistance to mechanical stress, thermal shock, and deformation.

-

Exceptional Thermal Stability: Can operate continuously at temperatures exceeding 1700°C without softening, cracking, or chemical degradation.

-

Chemical and Plasma Resistance: Inert to strong acids, alkalis, and reactive gases, suitable for semiconductor and laboratory environments.

-

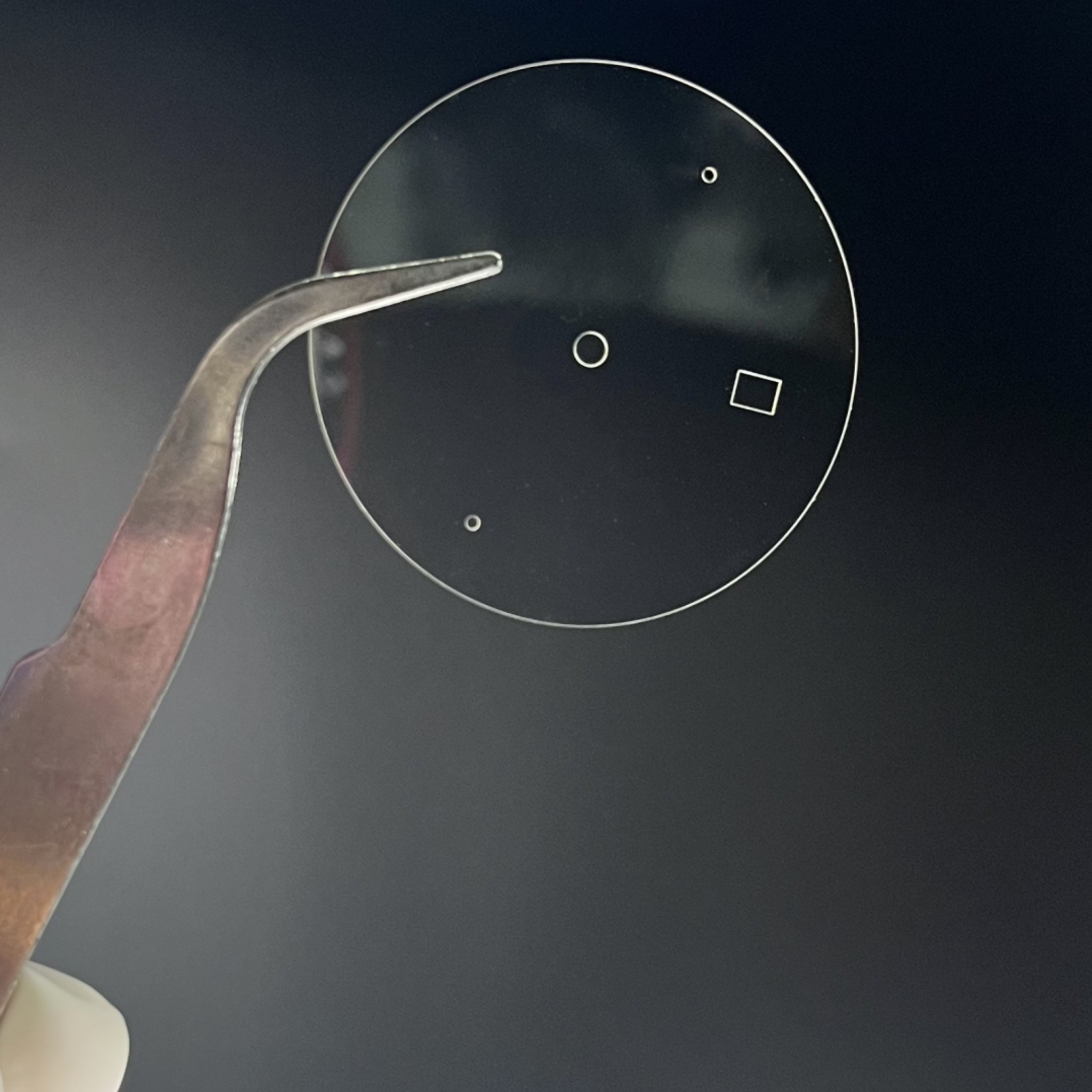

Smooth Surface Quality: The as-grown EFG surface is already fine and uniform, allowing optical polishing or coating if required.

-

Long Lifespan and Low Maintenance: Thanks to sapphire’s wear resistance, EFG tubes deliver long service life even under extreme use.

Applications

EFG sapphire tubes are used wherever transparency, strength, and stability are critical:

-

Semiconductor Equipment: Used as protective sleeves, gas injection tubes, and thermocouple sheaths.

-

Optoelectronics & Photonics: Laser tubes, optical sensors, and spectroscopy sample cells.

-

Industrial Processing: Viewing windows, plasma protection covers, and high-temperature reactors.

-

Medical & Analytical Fields: Flow channels, fluidic systems, and precision diagnostic instruments.

-

Energy & Aerospace Systems: High-pressure housings, combustion inspection ports, and thermal shielding components.

Typical Properties

| Parameter | Specification |

|---|---|

| Material Composition | Single Crystal Al₂O₃ (99.99% purity) |

| Growth Method | EFG (Edge-Defined Film-Fed Growth) |

| Diameter Range | 2 mm – 100 mm |

| Wall Thickness | 0.3 mm – 5 mm |

| Maximum Length | Up to 1200 mm |

| Orientation | a-axis, c-axis, or r-axis |

| Optical Transmission | 190 nm – 5000 nm |

| Operating Temperature | ≤1800°C in air / ≤2000°C in vacuum |

| Surface Finish | As-grown, polished, or precision ground |

FAQ

Q1: Why choose the EFG growth method for sapphire tubes?

A1: EFG enables near-net-shape growth, eliminating costly grinding and achieving longer, thinner tubes with accurate geometry.

Q2: Are EFG tubes resistant to chemical corrosion?

A2: Yes. Sapphire is chemically inert and resistant to most acids, alkalis, and halogen-based gases, outperforming quartz and alumina ceramics.

Q3: What customization options are available?

A3: Outer diameter, wall thickness, crystal orientation, and surface finish can all be tailored according to specific customer or equipment requirements.

Q4: How do EFG sapphire tubes compare with glass or quartz tubes?

A4: Unlike glass or quartz, sapphire tubes maintain clarity and mechanical integrity at extreme temperatures and resist scratching and erosion, offering much longer operational life.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.