EFG Grown Sapphire Tubes High-Performance Single Crystal Sapphire

Detailed Diagram

Overview

EFG sapphire tubes are precision-engineered tubular components fabricated from single-crystal sapphire (Al₂O₃) using the Edge-Defined Film-Fed Growth (EFG) process. Unlike conventional ceramic or polycrystalline tubes, EFG sapphire tubes offer unmatched mechanical integrity, thermal endurance, and chemical stability, making them an ideal choice for extreme environments and high-reliability systems.

By combining advanced crystal growth technology with tight dimensional control, EFG sapphire tubes serve as critical components in semiconductor manufacturing, optical systems, high-temperature processing, and scientific instrumentation.

EFG Technology – Direct Shaping Single Crystal Growth

The EFG (Edge-Defined Film-Fed Growth) method enables sapphire tubes to be grown directly into hollow cylindrical shapes, eliminating excessive machining and preserving crystal continuity.

Process Highlights:

-

High-purity aluminum oxide melt feeds through a capillary die

-

Tube geometry is defined precisely by the die profile

-

Continuous upward pulling produces a uniform single crystal tube

-

Growth conditions are tightly controlled to reduce internal stress

-

Post-growth annealing improves crystal stability and performance

This technique allows thin-wall sapphire tubes, long-length tubes, and complex cross-sections to be manufactured with excellent dimensional consistency.

Material Advantages of EFG Sapphire Tubes

EFG sapphire tubes inherit the intrinsic superiority of single-crystal sapphire while benefiting from shape-controlled growth.

Mechanical Performance

-

Mohs hardness of 9 (second only to diamond)

-

Excellent resistance to wear, scratching, and erosion

-

High compressive and flexural strength

Thermal Properties

-

Operating capability at temperatures exceeding 1600°C

-

Melting point approximately 2030°C

-

Low thermal expansion coefficient

-

Outstanding thermal shock resistance

Chemical Stability

-

Chemically inert to most acids, alkalis, and corrosive gases

-

No contamination or particle generation

-

Suitable for ultra-clean environments

Optical Characteristics

-

High transparency in visible and infrared ranges

-

Optional optical-grade polishing available

-

Suitable for optical monitoring and inspection windows

Application Scenarios

EFG sapphire tubes are widely applied in industries where traditional quartz or ceramic tubes cannot meet performance requirements.

Semiconductor & Electronics

-

Furnace protection tubes

-

Wafer processing and deposition equipment

-

Plasma and etching environment components

Optics & Photonics

-

Optical transmission tubes

-

High-power laser protection housings

-

UV and IR light guiding structures

High-Temperature & Chemical Processing

-

Thermocouple and sensor protection

-

Corrosive fluid or gas transport

-

Reactor liners and isolation tubes

Scientific & Industrial Equipment

-

Analytical instruments

-

Precision flow measurement systems

-

Aerospace and defense-related components

Standard & Custom Specifications

| Item | Specification Range |

|---|---|

| Material | Single Crystal Sapphire (Al₂O₃ ≥ 99.99%) |

| Growth Method | EFG (Edge-Defined Film-Fed Growth) |

| Outer Diameter | 2 mm – 120 mm (custom available) |

| Inner Diameter | Customized according to wall thickness |

| Wall Thickness | ≥ 0.2 mm |

| Length | Up to 2000 mm |

| Orientation | C-axis standard, others on request |

| Surface Condition | As-grown / Ground / Polished |

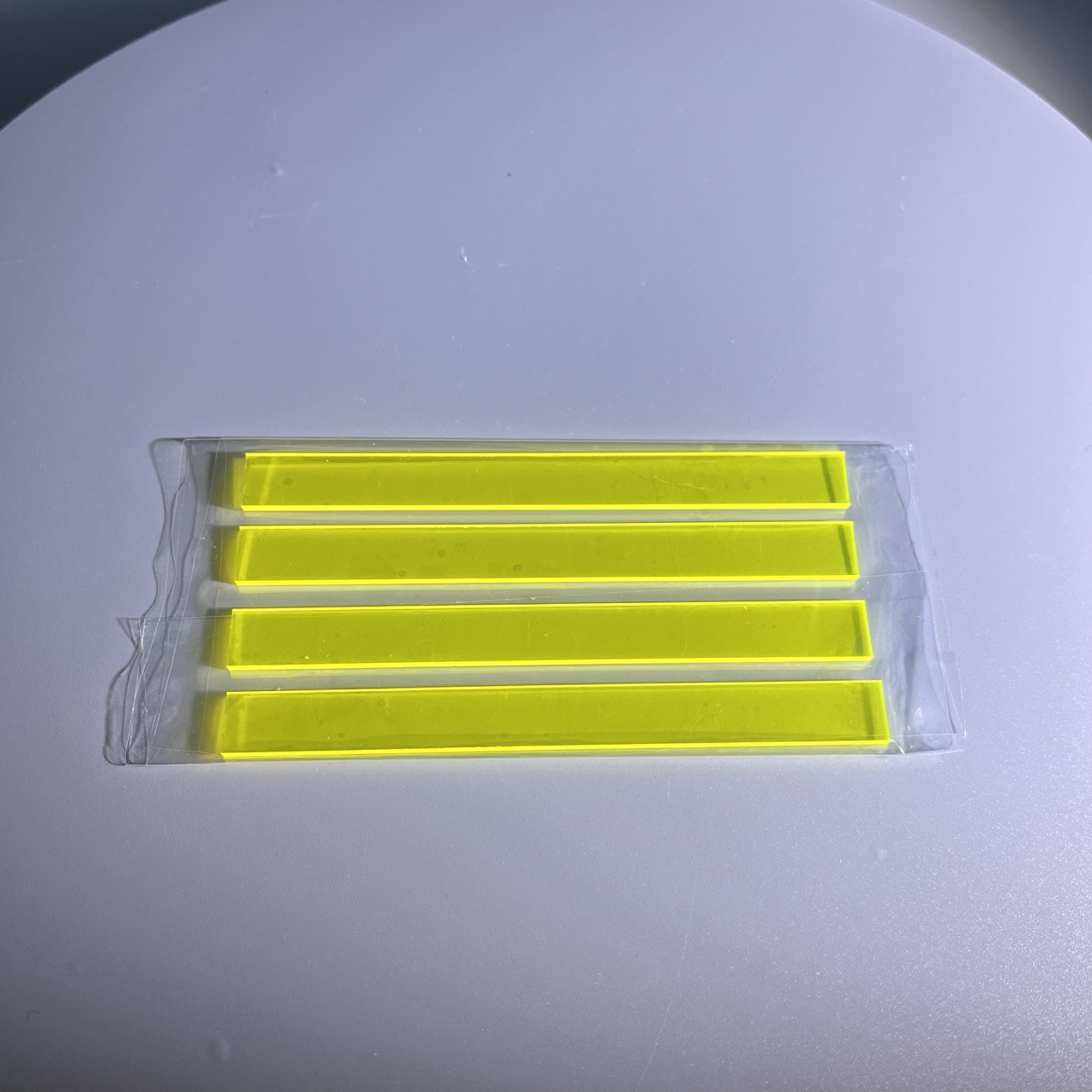

Transmittance test data of EFG sapphire tubes

Frequently Asked Questions (FAQ)

Q1: How does an EFG sapphire tube compare to quartz tubes?

EFG sapphire tubes offer significantly higher temperature resistance, better chemical durability, and longer operational life than quartz tubes.

Q2: Can EFG sapphire tubes be used in vacuum or plasma environments?

Yes. The dense single-crystal structure and chemical inertness make them suitable for vacuum, plasma, and reactive gas conditions.

Q3: Are thin-wall sapphire tubes feasible with EFG growth?

Yes. One of the key advantages of EFG technology is its ability to grow thin-wall, long-length sapphire tubes with stable geometry.

Q4: Do you support custom machining or end finishing?

Yes. Cutting, chamfering, polishing, and precision grinding services are available upon request.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.