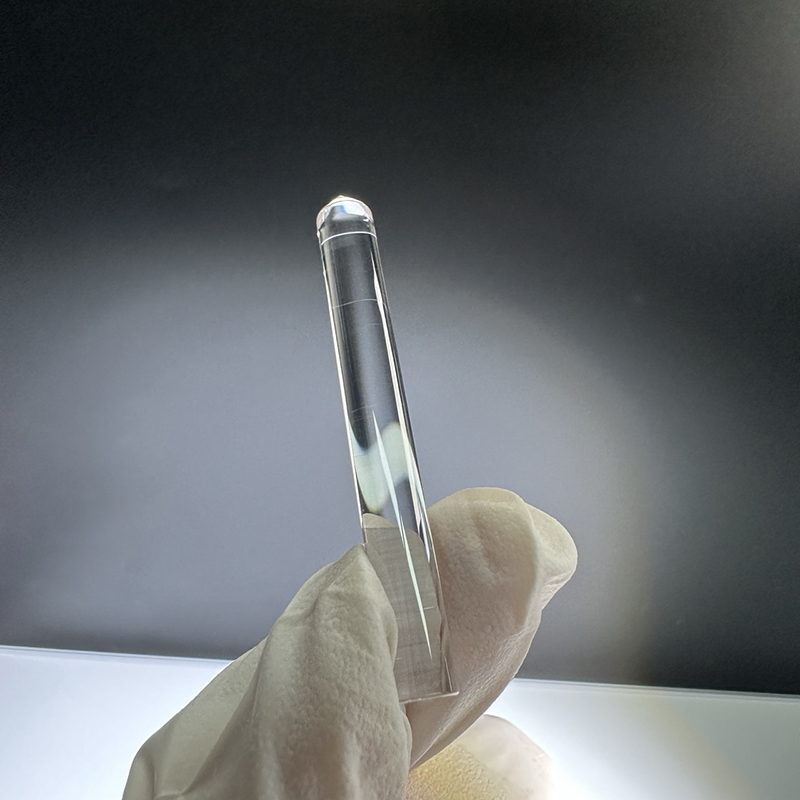

BF33 Glass Wafer Advanced Borosilicate Substrate 2″4″6″8″12″

Detailed Diagram

Overview of BF33 Glass Wafer

The BF33 glass wafer, internationally recognized under the trade name BOROFLOAT 33, is a premium-grade borosilicate float glass engineered by SCHOTT using a specialized microfloat production method. This manufacturing process delivers glass sheets with exceptionally uniform thickness, excellent surface flatness, minimal micro-roughness, and outstanding optical transparency.

A key distinguishing feature of BF33 is its low coefficient of thermal expansion (CTE) of approximately 3.3 × 10-6 K-1, making it an ideal match to silicon substrates. This property enables stress-free integration in microelectronics, MEMS, and optoelectronic devices.

Material Composition of BF33 Glass Wafer

BF33 belongs to the borosilicate glass family and contains over 80% silica (SiO2), alongside boron oxide (B2O3), alkali oxides, and trace amounts of aluminum oxide. This formulation provides:

-

Lower density compared to soda-lime glass, reducing overall component weight.

-

Reduced alkali content, minimizing ion leaching in sensitive analytical or biomedical systems.

-

Improved resistance to chemical attack from acids, alkalis, and organic solvents.

Production Process of BF33 Glass Wafer

BF33 glass wafers are produced through a series of precision-controlled steps. First, high-purity raw materials—mainly silica, boron oxide, and trace alkali and aluminum oxides—are accurately weighed and mixed. The batch is melted at high temperatures and refined to eliminate bubbles and impurities. Using the microfloat process, molten glass flows over molten tin to form highly flat, uniform sheets. These sheets are slowly annealed to relieve internal stress, then cut into rectangular plates and further blanked into round wafers. The wafer edges are beveled or chamfered for durability, followed by precision lapping and double-side polishing to achieve ultra-smooth surfaces. After ultrasonic cleaning in a cleanroom, each wafer undergoes rigorous inspection for dimensions, flatness, optical quality, and surface defects. Finally, wafers are packaged in contamination-free containers to ensure quality retention until use.

Mechanical Properties of BF33 Glass Wafer

| Product | BOROFLOAT 33 |

| Density | 2.23 g/cm3 |

| Modulus of Elasticity | 63 kN/mm2 |

| Knoop Hardness HK 0.1/20 | 480 |

| Poisson’s Ratio | 0.2 |

| Dielectric Constant (@ 1 MHz & 25°C) | 4.6 |

| Loss Tangent (@ 1 MHz & 25°C) | 37 x 10-4 |

| Dielectric Strength(@ 50 Hz & 25°C) | 16 kV/mm |

| Refractive Index | 1.472 |

| Dispersion (nF - nC) | 71.9 x 10-4 |

FAQ of BF33 Glass Wafer

What is BF33 glass?

BF33, also called BOROFLOAT® 33, is a premium borosilicate float glass manufactured by SCHOTT using a microfloat process. It offers low thermal expansion (~3.3 × 10⁻⁶ K⁻¹), excellent thermal shock resistance, high optical clarity, and outstanding chemical durability.

How is BF33 different from regular glass?

Compared to soda-lime glass, BF33:

-

Has a much lower coefficient of thermal expansion, reducing stress from temperature changes.

-

Is more chemically resistant to acids, alkalis, and solvents.

-

Offers higher UV and IR transmission.

-

Provides better mechanical strength and scratch resistance.

Why is BF33 used in semiconductor and MEMS applications?

Its thermal expansion closely matches silicon, making it ideal for anodic bonding and microfabrication. Its chemical durability also allows it to endure etching, cleaning, and high-temperature processes without degradation.

Can BF33 withstand high temperatures?

-

Continuous use: up to ~450 °C

-

Short-term exposure (≤ 10 hours): up to ~500 °C

Its low CTE also gives it excellent resistance to rapid thermal changes.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.