Double-Sided Precision Grinding Machine for SiC Sapphire Si wafer

Detailed Diagram

Introduction to Double-Sided Precision Grinding Equipment

The double-sided precision grinding equipment is an advanced machine tool engineered for synchronous processing of both surfaces of a workpiece. It delivers superior flatness and surface smoothness by grinding the upper and lower faces simultaneously. This technology is widely suitable for a broad material spectrum, covering metals (stainless steel, titanium, aluminum alloys), non-metals (technical ceramics, optical glass), and engineering polymers. Thanks to its dual-surface action, the system achieves excellent parallelism (≤0.002 mm) and ultra-fine surface roughness (Ra ≤0.1 μm), making it indispensable in automotive engineering, microelectronics, precision bearings, aerospace, and optical manufacturing.

When compared with single-sided grinders, this dual-face system provides higher throughput and reduced setup errors, since clamping accuracy is guaranteed by the simultaneous machining process. In combination with automated modules such as robotic loading/unloading, closed-loop force control, and online dimensional inspection, the equipment seamlessly integrates into smart factories and large-scale production environments.

Technical Data — Double-Sided Precision Grinding Equipment

| Item | Specification | Item | Specification |

|---|---|---|---|

| Grinding plate size | φ700 × 50 mm | Maximum pressure | 1000 kgf |

| Carrier dimension | φ238 mm | Upper plate speed | ≤160 rpm |

| Carrier number | 6 | Lower plate speed | ≤160 rpm |

| Workpiece thickness | ≤75 mm | Sun wheel rotation | ≤85 rpm |

| Workpiece diameter | ≤φ180 mm | Swing arm angle | 55° |

| Cylinder stroke | 150 mm | Power rating | 18.75 kW |

| Productivity (φ50 mm) | 42 pcs | Power cable | 3×16+2×10 mm² |

| Productivity (φ100 mm) | 12 pcs | Air requirement | ≥0.4 MPa |

| Machine footprint | 2200×2160×2600 mm | Net weight | 6000 kg |

How the Machine Works

1. Dual-Wheel Processing

Two opposed grinding wheels (diamond or CBN) rotate in opposite directions, applying uniform pressure across the workpiece held in planetary carriers. The dual action allows rapid removal with outstanding parallelism.

2. Positioning and Control

Precision ball screws, servo motors, and linear guides ensure positioning accuracy of ±0.001 mm. Integrated laser or optical gauges track thickness in real time, enabling automatic compensation.

3. Cooling & Filtration

A high-pressure fluid system minimizes thermal distortion and removes debris efficiently. The coolant is recirculated through multi-stage magnetic and centrifugal filtration, prolonging wheel life and stabilizing process quality.

4. Smart Control Platform

Equipped with Siemens/Mitsubishi PLCs and a touchscreen HMI, the control system allows recipe storage, real-time process monitoring, and fault diagnostics. Adaptive algorithms intelligently regulate pressure, rotation speed, and feed rates based on material hardness.

Applications of Double-Sided Precision Grinding Machine

Automotive Manufacturing

Machining crankshaft ends, piston rings, transmission gears, achieving ≤0.005 mm parallelism and surface roughness Ra ≤0.2 μm.

Semiconductor & Electronics

Thinning of silicon wafers for advanced 3D IC packaging; ceramic substrates ground with dimensional tolerance of ±0.001 mm.

Precision Engineering

Processing of hydraulic components, bearing elements, and shims where tolerances ≤0.002 mm are required.

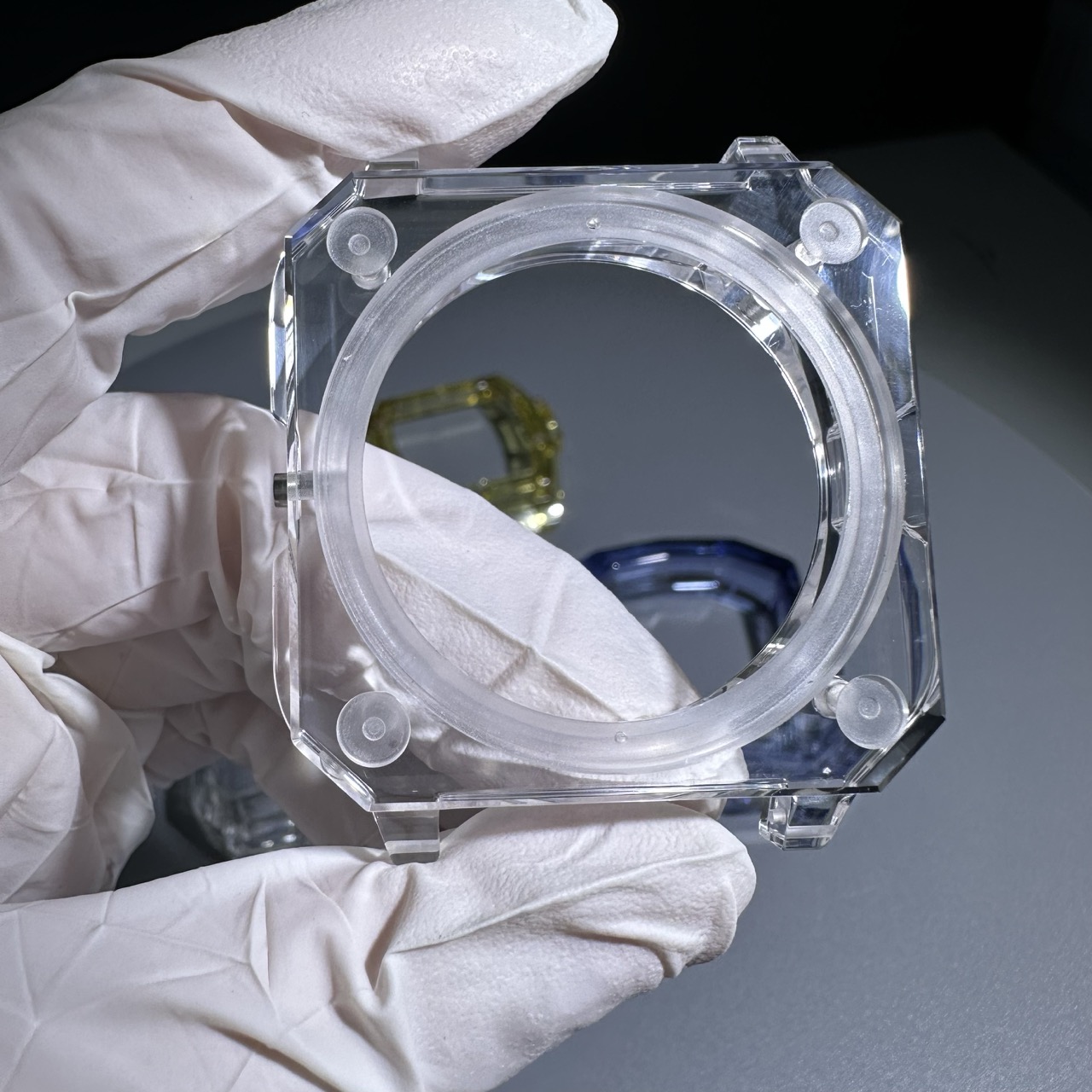

Optical Components

Finishing of smartphone cover glass (Ra ≤0.05 μm), sapphire lens blanks, and optical substrates with minimal internal stress.

Aerospace Applications

Machining of superalloy turbine tenons, ceramic insulation components, and lightweight structural parts used in satellites.

Key Advantages of Double-Sided Precision Grinding Machine

-

Rigid Construction

-

Heavy-duty cast iron frame with stress-relief treatment delivers low vibration and long-term stability.

-

Precision-grade bearings and high-rigidity ball screws achieve repeatability within 0.003 mm.

-

-

Intelligent User Interface

-

Fast PLC response (<1 ms).

-

Multilingual HMI supports recipe management and digital process visualization.

-

-

Flexible & Expandable

-

Modular compatibility with robotic arms and conveyor systems enables unmanned operation.

-

Accepts various wheel bonds (resin, diamond, CBN) for processing metals, ceramics, or composite parts.

-

-

Ultra-Precision Capability

-

Closed-loop pressure regulation ensures ±1% accuracy.

-

Dedicated tooling allows machining of non-standard components, such as turbine roots and precision sealing parts.

-

FAQ – Double-Sided Precision Grinding Machine

Q1: What materials can the Double-Sided Precision Grinding Machine process?

A1: The Double-Sided Precision Grinding Machine is capable of handling a wide range of materials, including metals (stainless steel, titanium, aluminum alloys), ceramics, engineering plastics, and optical glass. Specialized grinding wheels (diamond, CBN, or resin bond) can be selected based on the workpiece material.

Q2: What is the precision level of the Double-Sided Precision Grinding Machine?

A2: The machine achieves parallelism of ≤0.002 mm and surface roughness of Ra ≤0.1 μm. Positioning accuracy is maintained within ±0.001 mm thanks to servo-driven ball screws and in-line measurement systems.

Q3: How does the Double-Sided Precision Grinding Machine improve productivity compared with single-sided grinders?

A3: Unlike single-sided machines, the Double-Sided Precision Grinding Machine grinds both faces of the workpiece at the same time. This reduces cycle time, minimizes clamping errors, and significantly improves throughput—ideal for mass production lines.

Q4: Can the Double-Sided Precision Grinding Machine be integrated into automated production systems?

A4: Yes. The machine is designed with modular automation options, such as robotic loading/unloading, closed-loop pressure control, and in-line thickness inspection, making it fully compatible with smart factory environments.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.