12inch Fully Automatic Precision Dicing Saw Equipment Wafer Dedicated Cutting System for Si/SiC & HBM (Al)

Technical parameters

|

Parameter |

Specification |

|

Working Size |

Φ8", Φ12" |

|

Spindle |

Dual-axis 1.2/1.8/2.4/3.0, Max 60000 rpm |

|

Blade Size |

2" ~ 3" |

|

Y1 / Y2 Axis

|

Single-step increment: 0.0001 mm |

|

Positioning accuracy: < 0.002 mm |

|

|

Cutting range: 310 mm |

|

|

X Axis |

Feed speed range: 0.1–600 mm/s |

|

Z1 / Z2 Axis

|

Single-step increment: 0.0001 mm |

|

Positioning accuracy: ≤ 0.001 mm |

|

|

θ Axis |

Positioning accuracy: ±15" |

|

Cleaning Station

|

Rotation speed: 100–3000 rpm |

|

Cleaning method: Auto rinse & spin-dry |

|

|

Operating Voltage |

3-phase 380V 50Hz |

|

Dimensions (W×D×H) |

1550×1255×1880 mm |

|

Weight |

2100 kg |

Working Principle

The equipment achieves high-precision cutting through the following technologies:

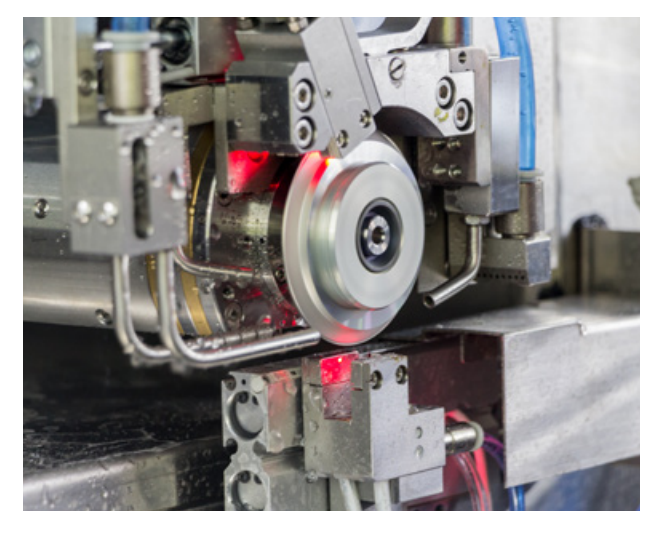

1.High-Rigidity Spindle System: Rotational speed up to 60,000 RPM, equipped with diamond blades or laser cutting heads to adapt to different material properties.

2.Multi-Axis Motion Control: X/Y/Z-axis positioning accuracy of ±1μm, paired with high-precision grating scales to ensure deviation-free cutting paths.

3.Intelligent Visual Alignment: High-resolution CCD (5 megapixels) automatically recognizes cutting streets and compensates for material warping or misalignment.

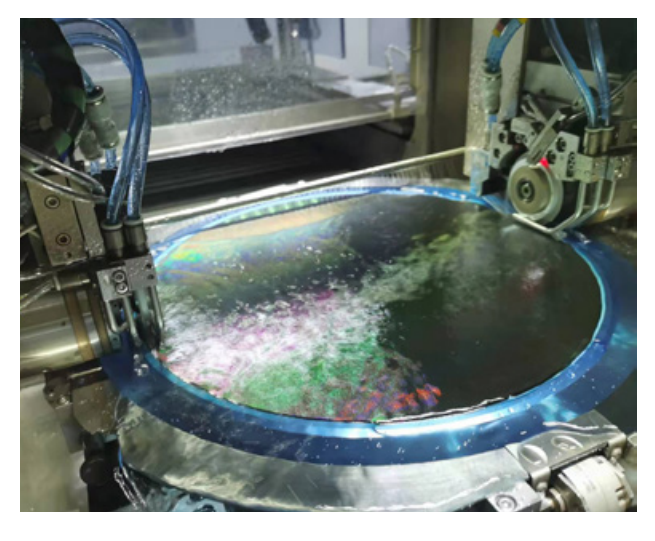

4.Cooling & Dust Removal: Integrated pure water cooling system and vacuum suction dust removal to minimize thermal impact and particle contamination.

Cutting Modes

1.Blade Dicing: Suitable for traditional semiconductor materials like Si and GaAs, with kerf widths of 50–100μm.

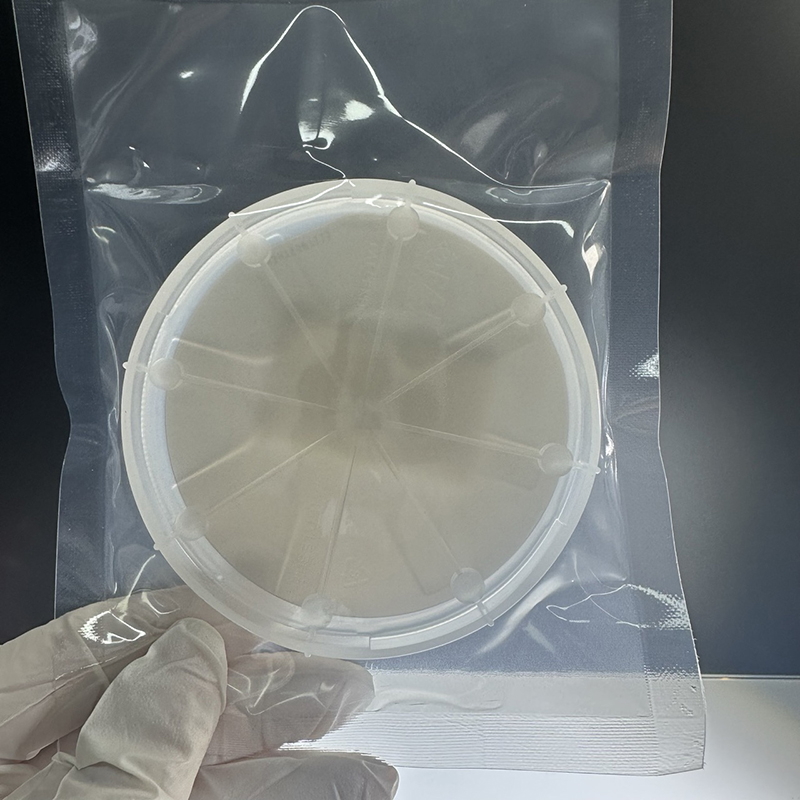

2.Stealth Laser Dicing: Used for ultra-thin wafers (<100μm) or fragile materials (e.g., LT/LN), enabling stress-free separation.

Typical Applications

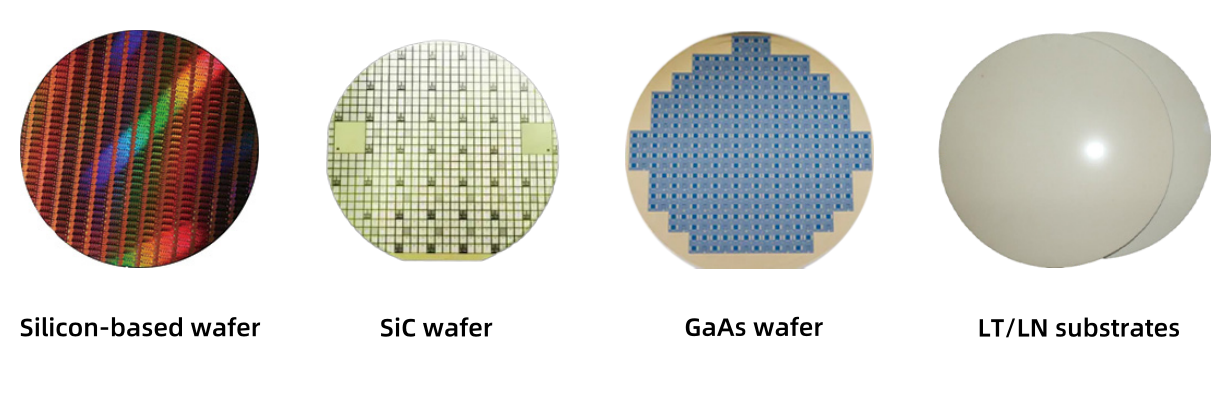

| Compatible Material | Application Field | Processing Requirements |

| Silicon (Si) | ICs, MEMS sensors | High-precision cutting, chipping <10μm |

| Silicon Carbide (SiC) | Power devices (MOSFET/diodes) | Low-damage cutting, thermal management optimization |

| Gallium Arsenide (GaAs) | RF devices, optoelectronic chips | Micro-crack prevention, cleanliness control |

| LT/LN Substrates | SAW filters, optical modulators | Stress-free cutting, preserving piezoelectric properties |

| Ceramic Substrates | Power modules, LED packaging | High-hardness material processing, edge flatness |

| QFN/DFN Frames | Advanced packaging | Multi-chip simultaneous cutting, efficiency optimization |

| WLCSP Wafers | Wafer-level packaging | Damage-free dicing of ultra-thin wafers (50μm) |

Advantages

1. High-speed cassette frame scanning with collision prevention alarms, rapid transfer positioning, and strong error-correction capability.

2. Optimized dual-spindle cutting mode, improving efficiency by approximately 80% compared to single-spindle systems.

3. Precision-imported ball screws, linear guides, and Y-axis grating scale closed-loop control, ensuring long-term stability of high-precision machining.

4. Fully automated loading/unloading, transfer positioning, alignment cutting, and kerf inspection, significantly reducing operator (OP) workload.

5.Gantry-style spindle mounting structure, with a minimum dual-blade spacing of 24mm, enabling broader adaptability for dual-spindle cutting processes.

Features

1.High-precision non-contact height measurement.

2.Multi-wafer dual-blade cutting on a single tray.

3.Automatic calibration, kerf inspection, and blade breakage detection systems.

4.Supports diverse processes with selectable automatic alignment algorithms.

5.Fault self-correction functionality and real-time multi-position monitoring.

6.First-cut inspection capability post-initial dicing.

7.Customizable factory automation modules and other optional functions.

Equipment Services

We provide comprehensive support from equipment selection to long-term maintenance:

(1) Customized Development

· Recommend blade/laser cutting solutions based on material properties (e.g., SiC hardness, GaAs brittleness).

· Offer free sample testing to verify cutting quality (including chipping, kerf width, surface roughness, etc.).

(2) Technical Training

· Basic Training: Equipment operation, parameter adjustment, routine maintenance.

· Advanced Courses: Process optimization for complex materials (e.g., stress-free cutting of LT substrates).

(3) After-Sales Support

· 24/7 Response: Remote diagnostics or on-site assistance.

· Spare Parts Supply: Stocked spindles, blades, and optical components for rapid replacement.

· Preventive Maintenance: Regular calibration to maintain accuracy and extend service life.

Our Advantages

✔ Industry Experience: Serving 300+ global semiconductor and electronics manufacturers.

✔ Cutting-Edge Technology: Precision linear guides and servo systems ensure industry-leading stability.

✔ Global Service Network: Coverage in Asia, Europe, and North America for localized support.

For testing or inquiries, contact us!