UV / IR Grade Quartz Through Hole Plates Custom Cut High Temperature Chemical

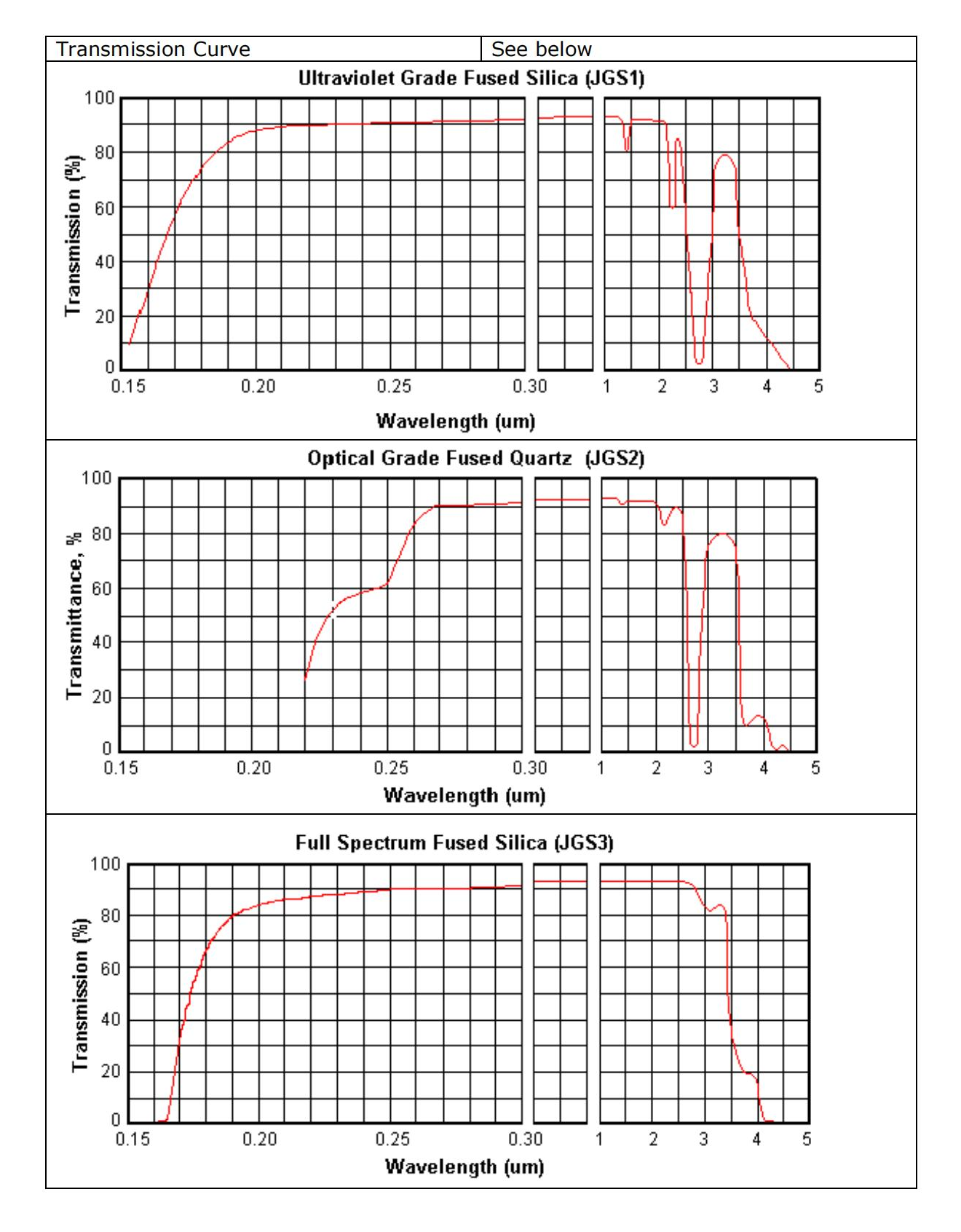

Detailed Diagram

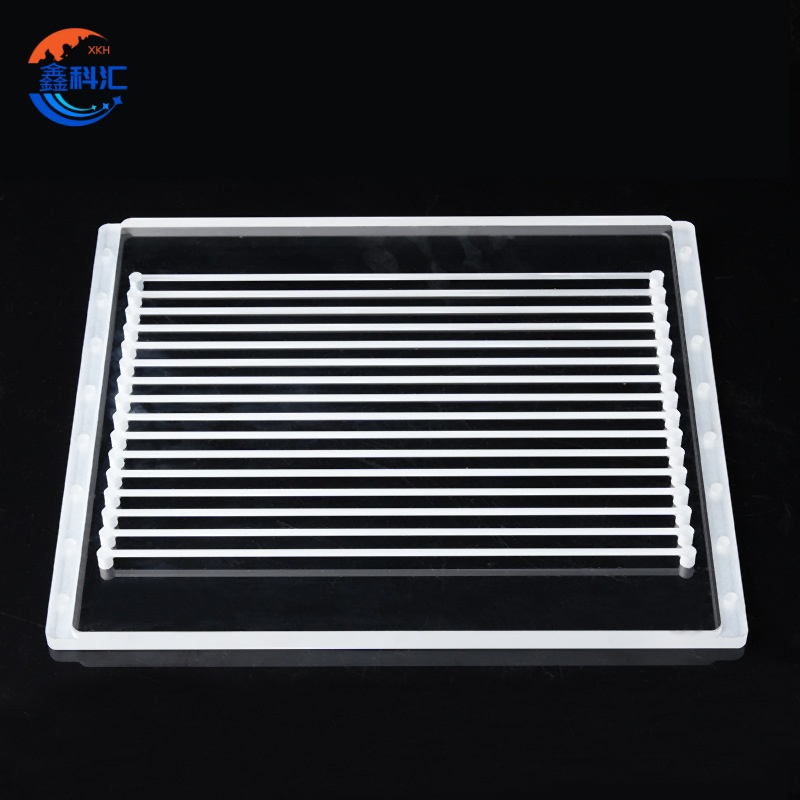

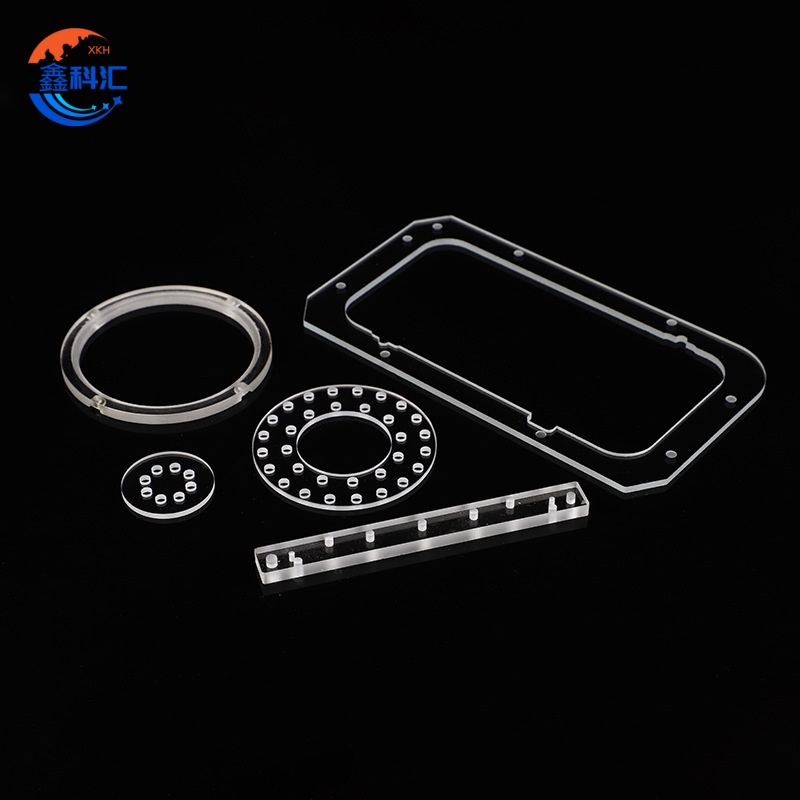

Overview of Quartz Plate

Quartz plates with through-holes are engineered components fabricated from high-purity silica glass, available in custom dimensions and complex geometries. These shaped quartz substrates are designed to support high-performance applications in optics, microfluidics, vacuum systems, and high-temperature manufacturing.

The integrated holes allow for beam alignment, gas flow, fiber feedthroughs, or mounting functions. The plates are offered in various material types to match spectral and thermal needs.

JGS Grade Classification

We offer quartz glass sheets in three standardized grades—JGS1, JGS2, and JGS3—each optimized for different optical and industrial applications. Understanding the distinction between these grades helps ensure you select the right material for your specific use.

JGS1 – UV Optical Grade (Synthetic Quartz)

-

Transmission Range: 180–2500 nm

-

Highlights: Exceptional UV transmittance, ultra-high purity, low hydroxyl and metal content

-

Use Cases: UV lasers, lithography, precision optics, UV curing systems

-

Production: Flame hydrolysis of high-purity SiCl₄

-

Notes: Ideal for deep-UV and high-precision optical systems

JGS2 – IR & Visible Grade (Fused Quartz)

-

Transmission Range: 260–3500 nm

-

Highlights: Strong IR and visible light transmission, cost-effective, stable under heat

-

Use Cases: Infrared windows, IR sensors, furnace viewports, light guides

-

Production: Fusion of natural quartz crystal

-

Notes: Not suitable for deep UV; great for thermal and optical devices

JGS3 – Industrial Grade (General Quartz Glass)

-

Transmission Range: Transparent in visible and IR; blocks UV below 260 nm

-

Highlights: Excellent thermal resistance, high chemical durability, low cost

-

Use Cases: Semiconductor heating elements, chemical containers, lamp covers

-

Production: Fused quartz with industrial-level clarity

-

Notes: Best for structural and high-temperature industrial use

JGS Grade

| Property | JGS1 (UV Grade) | JGS2 (IR Grade) | JGS3 (Industrial) |

|---|---|---|---|

| UV Transmission | ★★★★★ (Excellent) | ★☆☆☆☆ (Poor) | ☆☆☆☆☆ (Blocked) |

| IR Transmission | ★★★☆☆ | ★★★★★ | ★★★☆☆ |

| Optical Clarity | ★★★★★ | ★★★★☆ | ★★☆☆☆ |

| Thermal Resistance | ★★★★☆ | ★★★★☆ | ★★★★★ |

| Purity Level | Ultra-high | High | Medium |

| Recommended Usage | Precision optics, UV | IR optics, heat view | Industrial, heating |

How They’re Made of Quartz Plate

Laser drilling is a high-precision, non-contact method used to create holes in fused quartz glass by focusing a concentrated laser beam on the material surface. The intense energy of the laser rapidly heats and vaporizes the quartz, forming clean holes without causing cracks or mechanical stress.

This technique is especially suitable for microholes (as small as 10 microns), high-density patterns, and fragile quartz components. Femtosecond or picosecond lasers are commonly used to minimize heat-affected zones and achieve smooth edges with excellent accuracy.

Laser drilling is widely applied in microfluidics, semiconductors, optics, and advanced scientific instruments that require precision and reliability.

Mechanical Properties of Quartz Plate

| Quartz Characteristic | |

| SIO2 | 99.99% |

| Density | 2.2(g/cm3) |

| Degree of the hardness moh’ scale | 6.6 |

| Melting point | 1732℃ |

| Working temperature | 1100℃ |

| Max temperature can reach in a short time | 1450℃ |

| Acid tolerance | 30 times than ceramic,150 times than stainless |

| Visible light transmittance | Above 93% |

| UV spectral region transmittance | 80% |

| Resistance value | 10000 times than ordinary glass |

| Annealing point | 1180℃ |

| Softening point | 1630℃ |

| Strain point | 1100℃ |

FAQ of Quartz Plate

Q1: Can I order quartz windows with thicknesses other than 8.2 mm?

Absolutely! While 8.2 mm is a popular standard, we support custom thicknesses from 1 mm to 25 mm. Please contact us with your specifications.

Q2: What grades of quartz are available?

We offer:

-

JGS1 (UV grade): Excellent deep UV transmission down to 185 nm

-

JGS2 (optical grade): High clarity in the visible to near-IR range

-

JGS3 (IR grade): Optimized for near- and mid-IR applications with superior thermal resistance

Q3: Do you provide AR coatings?

Yes, anti-reflection coatings for UV, visible, NIR, or broadband ranges are available, applied with high uniformity to meet your optical system needs.

Q4: Can quartz windows withstand chemical exposure?

Yes. Quartz windows are highly resistant to most acids, bases, and solvents, making them ideal for harsh chemical environments.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.