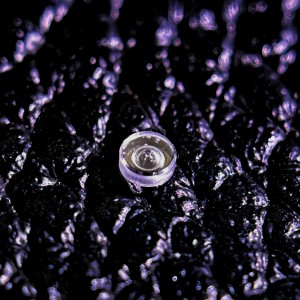

Through-Hole Transparent Sapphire Components

Detailed Diagram

Overview

Through-hole transparent sapphire components are precision-engineered parts fabricated from single-crystal aluminum oxide (Al₂O₃), a material renowned for its combination of optical transparency, superior hardness, and chemical inertness. These components feature precision-drilled holes that enable mechanical integration, optical alignment, or controlled flow channels while maintaining excellent optical and structural performance. Their unique combination of optical and mechanical functions makes them indispensable in semiconductor, aerospace, photonics, and instrumentation industries.

Material Characteristics

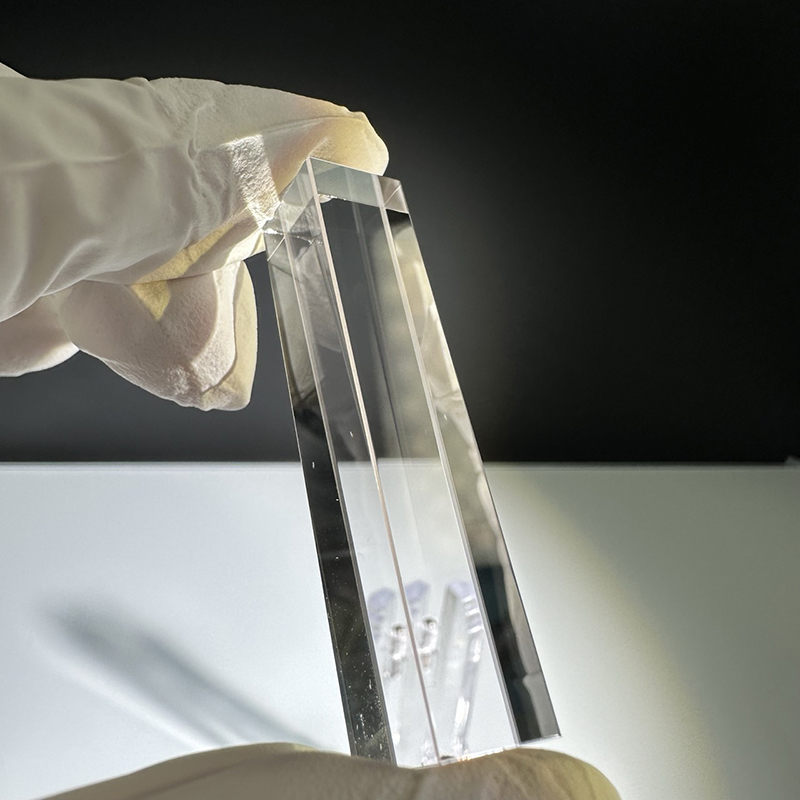

Sapphire’s exceptional properties stem from its single-crystal structure and chemical stability. With a hardness of 9 on the Mohs scale, sapphire offers outstanding abrasion resistance and dimensional stability even under high loads. It is optically transparent across a wide spectral range—from deep ultraviolet (UV) through visible light to mid-infrared (IR)—and retains clarity under high thermal stress. Sapphire’s melting point exceeds 2000°C, and it exhibits excellent resistance to acids, alkalis, and plasma exposure.

Core Benefits

-

Superior Transparency: Transmission range from 190 nm to 5000 nm, ensuring minimal optical loss in UV–IR systems.

-

Outstanding Mechanical Strength: High compressive and flexural strength for use in pressure and vacuum chambers.

-

Thermal Robustness: Maintains structural and optical performance at extreme temperatures.

-

Chemical and Plasma Resistance: Non-reactive to most chemical reagents and stable in plasma or corrosive atmospheres.

-

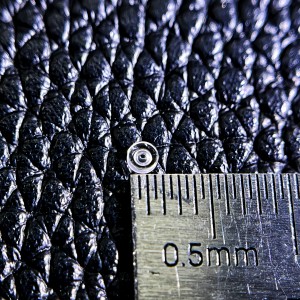

Precision Engineering: Through-holes can be drilled, countersunk, or tapered with tolerances within ±5 µm.

-

Long-Term Reliability: No degradation in optical or mechanical properties over prolonged use.

Applications

-

Semiconductor Manufacturing:

Used as inspection windows, gas nozzles, or isolation components in CVD, PECVD, and etching equipment, where thermal stability and cleanliness are essential. -

Optical and Photonic Devices:

Functions as optical mounts, sensor windows, or light guide interfaces that require through-holes for alignment, fiber coupling, or laser beam passage. -

Aerospace and Defense:

Integrated into high-precision optical sensors, imaging systems, and protective covers operating under vibration, impact, or thermal stress. -

Analytical and Medical Equipment:

Applied in flow cells, sample chambers, and diagnostic systems for spectroscopy or microfluidic analysis. -

Industrial and Research Instrumentation:

Serves as wear-resistant mechanical spacers, alignment jigs, and precision holders in experimental and metrology setups.

Typical Specifications

| Property | Specification |

|---|---|

| Material | Single-Crystal Sapphire (Al₂O₃ ≥ 99.99%) |

| Orientation | C-axis, A-axis, or R-axis (optional) |

| Outer Diameter | 2 mm – 100 mm |

| Thickness | 0.3 mm – 20 mm |

| Hole Diameter | 0.2 mm – 10 mm (customizable) |

| Optical Transmission | >85% (400–2000 nm) |

| Surface Flatness | λ/10 or better |

| Parallelism | ≤3 arcmin |

| Scratch-Dig | 10-5, 20-10 optional |

| Temperature Range | −200°C to +2000°C |

| Coating Options | AR, HR, DLC, or custom thin film coatings |

FAQ

Q1: What makes sapphire through-hole components suitable for semiconductor systems?

A1: Sapphire combines electrical insulation with high purity, temperature resistance, and chemical stability, making it ideal for plasma chambers, optical monitoring ports, and alignment components.

Q2: Can through-holes be drilled at an angle or with conical geometry?

A2: Yes. Sapphire can be laser-drilled or ultrasonically machined at various angles to achieve optical axis alignment or fluid control functions.

Q3: Are coatings or surface treatments available?

A3: Multiple coatings such as anti-reflective, infrared-enhanced, or diamond-like carbon (DLC) can be applied to improve performance under specific spectral or mechanical conditions.

Q4: What tolerances can be achieved?

A4: Dimensional tolerances within ±5 µm and angular tolerances under 3 arcmin can be achieved through precision CNC and polishing control.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.