Soda-Lime Glass Substrates – Precision Polished and Cost-Effective for Industry Us

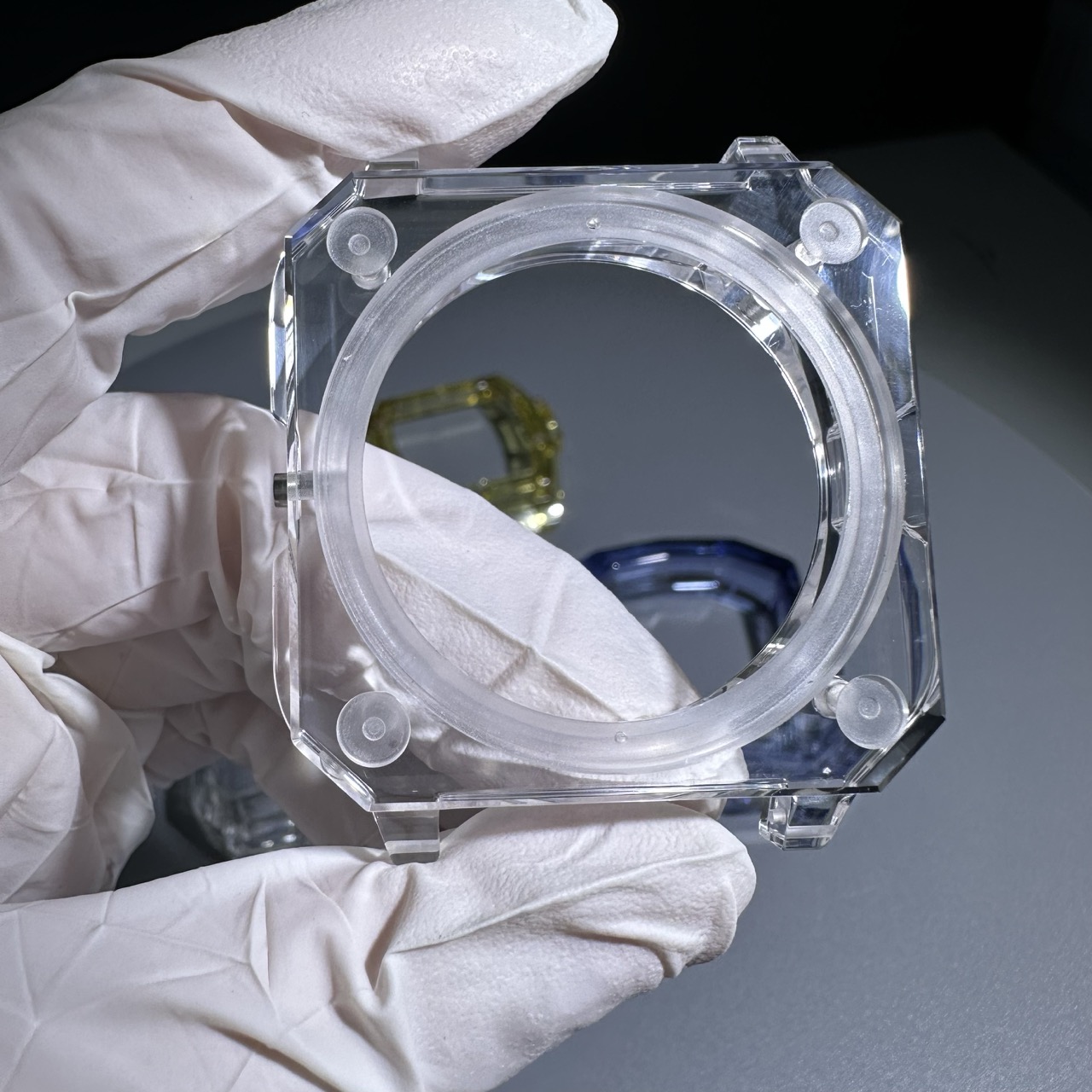

Detailed Diagram

Overview of Quartz Glass

Soda-lime substrates are precision glass wafers made from high-grade soda-lime silicate glass — a versatile and cost-efficient material widely used in optical, electronic, and coating industries. Known for its excellent light transmission, flat surface quality, and mechanical stability, soda-lime glass provides a reliable foundation for various thin-film deposition, photolithography, and laboratory applications.

Its balanced physical and optical performance makes it a practical choice for both R&D and volume production environments.

Key Features & Benefits

-

High Optical Clarity: Exceptional transmission in the visible spectrum (400–800 nm), suitable for optical inspection and imaging.

-

Smooth Polished Surface: Both sides can be finely polished to achieve low surface roughness (<2 nm), ensuring excellent adhesion for coatings.

-

Dimensional Stability: Maintains consistent flatness and parallelism, compatible with precision alignment and metrology setups.

-

Cost-Effective Material: Offers a low-cost alternative to borosilicate or fused silica substrates for standard temperature applications.

-

Machinability: Easily cut, drilled, or shaped for custom optical and electronic designs.

-

Chemical Compatibility: Compatible with photoresists, adhesives, and most thin-film deposition materials (ITO, SiO₂, Al, Au).

With its combination of clarity, strength, and affordability, soda-lime glass remains one of the most commonly used substrate materials in laboratories, optical workshops, and thin-film coating facilities.

Manufacturing & Surface Quality

Each soda-lime substrate is fabricated using high-quality float glass that undergoes precision slicing, lapping, and double-sided polishing to achieve an optically flat surface.

Typical manufacturing steps include:

-

Float Process: Producing ultra-flat, uniform glass sheets via molten tin float technology.

-

Cutting & Shaping: Laser or diamond cutting into round or rectangular substrate formats.

-

Fine Polishing: Achieving high flatness and optical-grade smoothness on one or both sides.

-

Cleaning & Packaging: Ultrasonic cleaning in deionized water, particle-free inspection, and cleanroom packaging.

These processes ensure superior consistency and surface finish suitable for optical coating or microfabrication work.

Applications

Soda-lime substrates are used in a broad range of scientific, optical, and semiconductor applications, including:

-

Optical Windows & Mirrors: Base plates for optical coatings and filter fabrication.

-

Thin-Film Deposition: Ideal carrier substrates for ITO, SiO₂, TiO₂, and metallic films.

-

Display Technology: Used in backplane glass, display protection, and calibration samples.

-

Semiconductor Research: Low-cost carriers or test wafers in photolithography processes.

-

Laser & Sensor Platforms: Transparent support material for optical alignment and probe testing.

-

Educational & Experimental Use: Commonly used in labs for coating, etching, and bonding experiments.

Typical Specifications

| Parameter | Specification |

|---|---|

| Material | Soda-Lime Silicate Glass |

| Diameter | 2", 3", 4", 6", 8" (customized available) |

| Thickness | 0.3–1.1 mm standard |

| Surface Finish | Double-side polished or single-side polished |

| Flatness | ≤15 µm |

| Surface Roughness (Ra) | <2 nm |

| Transmission | ≥90% (Visible range: 400–800 nm) |

| Density | 2.5 g/cm³ |

| Coefficient of Thermal Expansion | ~9 × 10⁻⁶ /K |

| Hardness | ~6 Mohs |

| Refractive Index (nD) | ~1.52 |

FAQ

Q1: What are soda-lime substrates commonly used for?

A: They are used as base materials for thin-film coating, optical experiments, photolithography testing, and optical window production due to their clarity and flatness.

Q2: Can soda-lime substrates withstand high temperatures?

A: They can operate up to around 300°C. For higher temperature resistance, borosilicate or fused silica substrates are recommended.

Q3: Are the substrates suitable for coating deposition?

A: Yes, their smooth and clean surfaces are ideal for physical vapor deposition (PVD), chemical vapor deposition (CVD), and sputtering processes.

Q4: Is customization possible?

A: Absolutely. Custom sizes, shapes, thicknesses, and edge finishes are available based on specific application requirements.

Q5: How do they compare to borosilicate substrates?

A: Soda-lime glass is more economical and easier to process but has slightly lower thermal and chemical resistance compared to borosilicate glass.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.