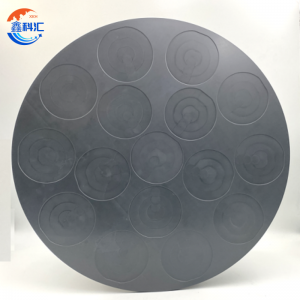

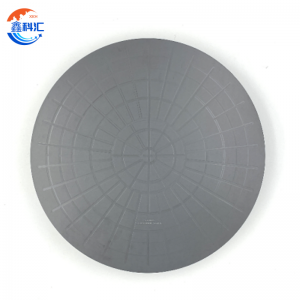

Silicon Carbide Ceramic Tray – Durable, High-Performance Trays for Thermal and Chemical Applications

Detailed Diagram

Product Introduction

Silicon carbide (SiC) ceramic trays are high-performance components widely used in high-temperature, high-load, and chemically harsh industrial environments. Engineered from advanced silicon carbide ceramic materials, these trays are designed to deliver exceptional mechanical strength, superior thermal conductivity, and excellent resistance to thermal shock, oxidation, and corrosion. Their robust nature makes them highly suitable for various industrial applications including semiconductor manufacturing, photovoltaic processing, sintering of powder metallurgy parts, and more.

Silicon carbide trays serve as essential carriers or supports during thermal treatment processes where dimensional accuracy, structural integrity, and chemical resistance are critical. Compared to traditional ceramic materials such as alumina or mullite, SiC trays offer significantly higher performance, especially in conditions involving repeated thermal cycling and aggressive atmospheres.

Manufacturing Process & Material Composition

The production of SiC ceramic trays involves precision engineering and advanced sintering technologies to ensure high density, uniform microstructure, and consistent performance. The general steps include:

-

Raw Material Selection

High-purity silicon carbide powder (≥99%) is selected, often with specific particle size control and minimal impurities to guarantee high mechanical and thermal properties. -

Forming Methods

Depending on tray specifications, different forming techniques are employed:-

Cold Isostatic Pressing (CIP) for high-density, uniform compacts

-

Extrusion or slip casting for complex shapes

-

Injection molding for precise, detailed geometries

-

-

Sintering Techniques

The green body is sintered at ultra-high temperatures, typically in the range of 2000°C, under inert or vacuum atmospheres. Common sintering methods include:-

Reaction Bonded SiC (RB-SiC)

-

Pressureless Sintered SiC (SSiC)

-

Recrystallized SiC (RBSiC)

Each method results in slightly different material properties, such as porosity, strength, and thermal conductivity.

-

-

Precision Machining

After sintering, the trays are machined to achieve tight dimensional tolerances, smooth surface finish, and flatness. Surface treatments such as lapping, grinding, and polishing can be applied based on customer needs.

Typical Applications

Silicon carbide ceramic trays are used in a wide variety of industries due to their versatility and resilience. Common applications include:

-

Semiconductor Industry

SiC trays are used as carriers during wafer annealing, diffusion, oxidation, epitaxy, and implantation processes. Their stability ensures uniform temperature distribution and minimal contamination. -

Photovoltaic (PV) Industry

In solar cell production, SiC trays support silicon ingots or wafers during high-temperature diffusion and sintering steps. -

Powder Metallurgy and Ceramics

Used for supporting components during sintering of metal powders, ceramics, and composite materials. -

Glass and Display Panels

Applied as kiln trays or platforms for manufacturing special glasses, LCD substrates, or other optical components. -

Chemical Processing and Thermal Furnaces

Serve as corrosion-resistant carriers in chemical reactors or as thermal support trays in vacuum and controlled-atmosphere furnaces.

Key Performance Features

-

✅ Exceptional Thermal Stability

Withstands continuous use in temperatures up to 1600–2000°C without warping or degradation. -

✅ High Mechanical Strength

Offers high flexural strength (typically >350 MPa), ensuring long-term durability even under high load conditions. -

✅ Thermal Shock Resistance

Excellent performance in environments with rapid temperature fluctuations, minimizing the risk of cracking. -

✅ Corrosion and Oxidation Resistance

Chemically stable in most acids, alkalis, and oxidizing/reducing gases, suitable for harsh chemical processes. -

✅ Dimensional Accuracy and Flatness

Machined to high precision, ensuring uniform processing and compatibility with automated systems. -

✅ Long Lifespan & Cost-Efficiency

Lower replacement rates and reduced maintenance costs make it a cost-effective solution over time.

Technical Specifications

| Parameter | Typical Value |

|---|---|

| Material | Reaction Bonded SiC / Sintered SiC |

| Max. Operating Temperature | 1600–2000°C |

| Flexural Strength | ≥350 MPa |

| Density | ≥3.0 g/cm³ |

| Thermal Conductivity | ~120–180 W/m·K |

| Surface Flatness | ≤ 0.1 mm |

| Thickness | 5–20 mm (customizable) |

| Dimensions | Standard: 200×200 mm, 300×300 mm, etc. |

| Surface Finish | Machined, polished (upon request) |

Frequently Asked Questions (FAQ)

Q1: Can silicon carbide trays be used in vacuum furnaces?

A: Yes, SiC trays are ideal for vacuum environments due to their low outgassing, chemical stability, and high-temperature resistance.

Q2: Are custom shapes or slots available?

A: Absolutely. We offer customization services including tray size, shape, surface features (e.g., grooves, holes), and surface polishing to meet unique customer requirements.

Q3: How does SiC compare with alumina or quartz trays?

A: SiC has higher strength, better thermal conductivity, and superior resistance to thermal shock and chemical corrosion. While alumina is more cost-effective, SiC performs better in demanding environments.

Q4: Is there a standard thickness for these trays?

A: Thickness is typically in the range of 5–20 mm, but we can adjust it based on your application and load-bearing requirements.

Q5: What is the typical lead time for customized SiC trays?

A: Lead times vary depending on the complexity and quantity but generally range from 2 to 4 weeks for customized orders.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.