SiC Ingot Growth Furnace for Large-Diameter SiC Crystal TSSG/LPE Methods

Working Principle

The core principle of liquid-phase silicon carbide ingot growth involves dissolving high-purity SiC raw materials in molten metals (e.g., Si, Cr) at 1800-2100°C to form saturated solutions, followed by controlled directional growth of SiC single crystals on seed crystals through precise temperature gradient and supersaturation regulation. This technology is particularly suitable for producing high-purity (>99.9995%) 4H/6H-SiC single crystals with low defect density (<100/cm²), meeting stringent substrate requirements for power electronics and RF devices. The liquid-phase growth system enables precise control of crystal conductivity type (N/P type) and resistivity through optimized solution composition and growth parameters.

Core Components

1. Special Crucible System: High-purity graphite/tantalum composite crucible, temperature resistance >2200°C, resistant to SiC melt corrosion.

2. Multi-zone Heating System: Combined resistance/induction heating with temperature control accuracy of ±0.5°C (1800-2100°C range).

3. Precision Motion System: Dual closed-loop control for seed rotation (0-50rpm) and lifting (0.1-10mm/h).

4. Atmosphere Control System: High-purity argon/nitrogen protection, adjustable working pressure (0.1-1atm).

5. Intelligent Control System: PLC+industrial PC redundant control with real-time growth interface monitoring.

6. Efficient Cooling System: Graded water cooling design ensures long-term stable operation.

TSSG vs. LPE Comparison

| Characteristics | TSSG Method | LPE Method |

| Growth Temp | 2000-2100°C | 1500-1800°C |

| Growth Rate | 0.2-1mm/h | 5-50μm/h |

| Crystal Size | 4-8 inch ingots | 50-500μm epi-layers |

| Main Application | Substrate preparation | Power device epi-layers |

| Defect Density | <500/cm² | <100/cm² |

| Suitable Polytypes | 4H/6H-SiC | 4H/3C-SiC |

Key Applications

1. Power Electronics: 6-inch 4H-SiC substrates for 1200V+ MOSFETs/diodes.

2. 5G RF Devices: Semi-insulating SiC substrates for base station PAs.

3. EV Applications: Ultra-thick (>200μm) epi-layers for automotive-grade modules.

4. PV Inverters: Low-defect substrates enabling >99% conversion efficiency.

Core Advantages

1. Technological Superiority

1.1 Integrated Multi-Method Design

This liquid-phase SiC ingot growth system innovatively combines TSSG and LPE crystal growth technologies. The TSSG system employs top-seeded solution growth with precise melt convection and temperature gradient control (ΔT≤5℃/cm), enabling stable growth of 4-8 inch large-diameter SiC ingots with single-run yields of 15-20kg for 6H/4H-SiC crystals. The LPE system utilizes optimized solvent composition (Si-Cr alloy system) and supersaturation control (±1%) to grow high-quality thick epitaxial layers with defect density <100/cm² at relatively low temperatures (1500-1800℃).

1.2 Intelligent Control System

Equipped with 4th-generation smart growth control featuring:

• Multi-spectral in-situ monitoring (400-2500nm wavelength range)

• Laser-based melt level detection (±0.01mm precision)

• CCD-based diameter closed-loop control (<±1mm fluctuation)

• AI-powered growth parameter optimization (15% energy saving)

2. Process Performance Advantages

2.1 TSSG Method Core Strengths

• Large-size capability: Supports up to 8-inch crystal growth with >99.5% diameter uniformity

• Superior crystallinity: Dislocation density <500/cm², micropipe density <5/cm²

• Doping uniformity: <8% n-type resistivity variation (4-inch wafers)

• Optimized growth rate: Adjustable 0.3-1.2mm/h, 3-5× faster than vapor-phase methods

2.2 LPE Method Core Strengths

• Ultra-low defect epitaxy: Interface state density <1×10¹¹cm⁻²·eV⁻¹

• Precise thickness control: 50-500μm epi-layers with <±2% thickness variation

• Low-temperature efficiency: 300-500℃ lower than CVD processes

• Complex structure growth: Supports p-n junctions, superlattices, etc.

3. Production Efficiency Advantages

3.1 Cost Control

• 85% raw material utilization (vs. 60% conventional)

• 40% lower energy consumption (compared to HVPE)

• 90% equipment uptime (modular design minimizes downtime)

3.2 Quality Assurance

• 6σ process control (CPK>1.67)

• Online defect detection (0.1μm resolution)

• Full-process data traceability (2000+ real-time parameters)

3.3 Scalability

• Compatible with 4H/6H/3C polytypes

• Upgradeable to 12-inch process modules

• Supports SiC/GaN hetero-integration

4. Industry Application Advantages

4.1 Power Devices

• Low-resistivity substrates (0.015-0.025Ω·cm) for 1200-3300V devices

• Semi-insulating substrates (>10⁸Ω·cm) for RF applications

4.2 Emerging Technologies

• Quantum communication: Ultra-low noise substrates (1/f noise<-120dB)

• Extreme environments: Radiation-resistant crystals (<5% degradation after 1×10¹⁶n/cm² irradiation)

XKH Services

1. Customized Equipment: Tailored TSSG/LPE system configurations.

2. Process Training: Comprehensive technical training programs.

3. After-sales Support: 24/7 technical response and maintenance.

4. Turnkey Solutions: Full-spectrum service from installation to process validation.

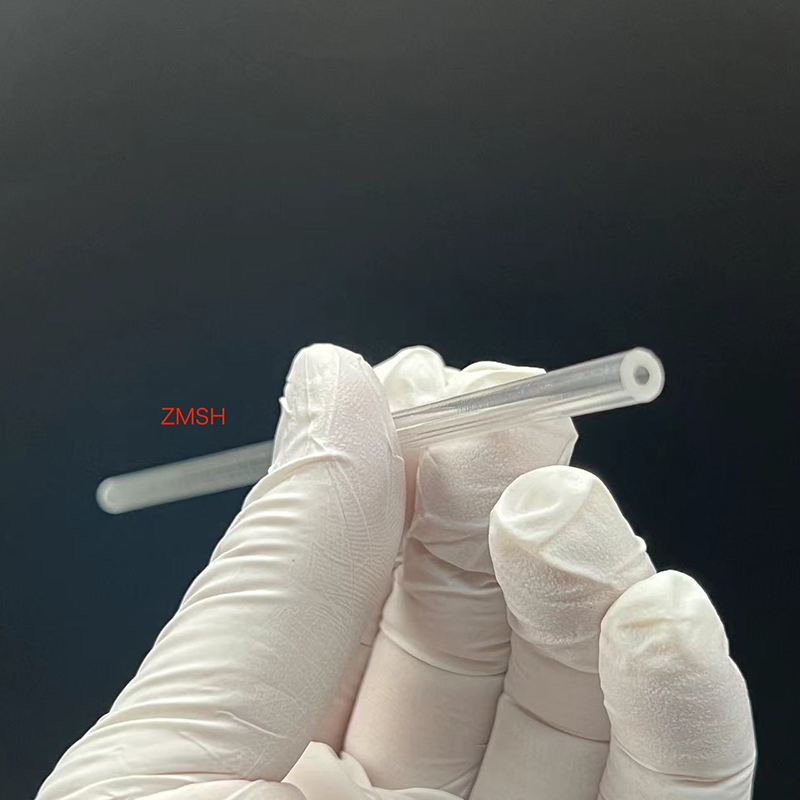

5. Material Supply: 2-12 inch SiC substrates/epi-wafers available.

Key advantages include:

• Up to 8-inch crystal growth capability.

• Resistivity uniformity <0.5%.

• Equipment uptime >95%.

• 24/7 technical support.