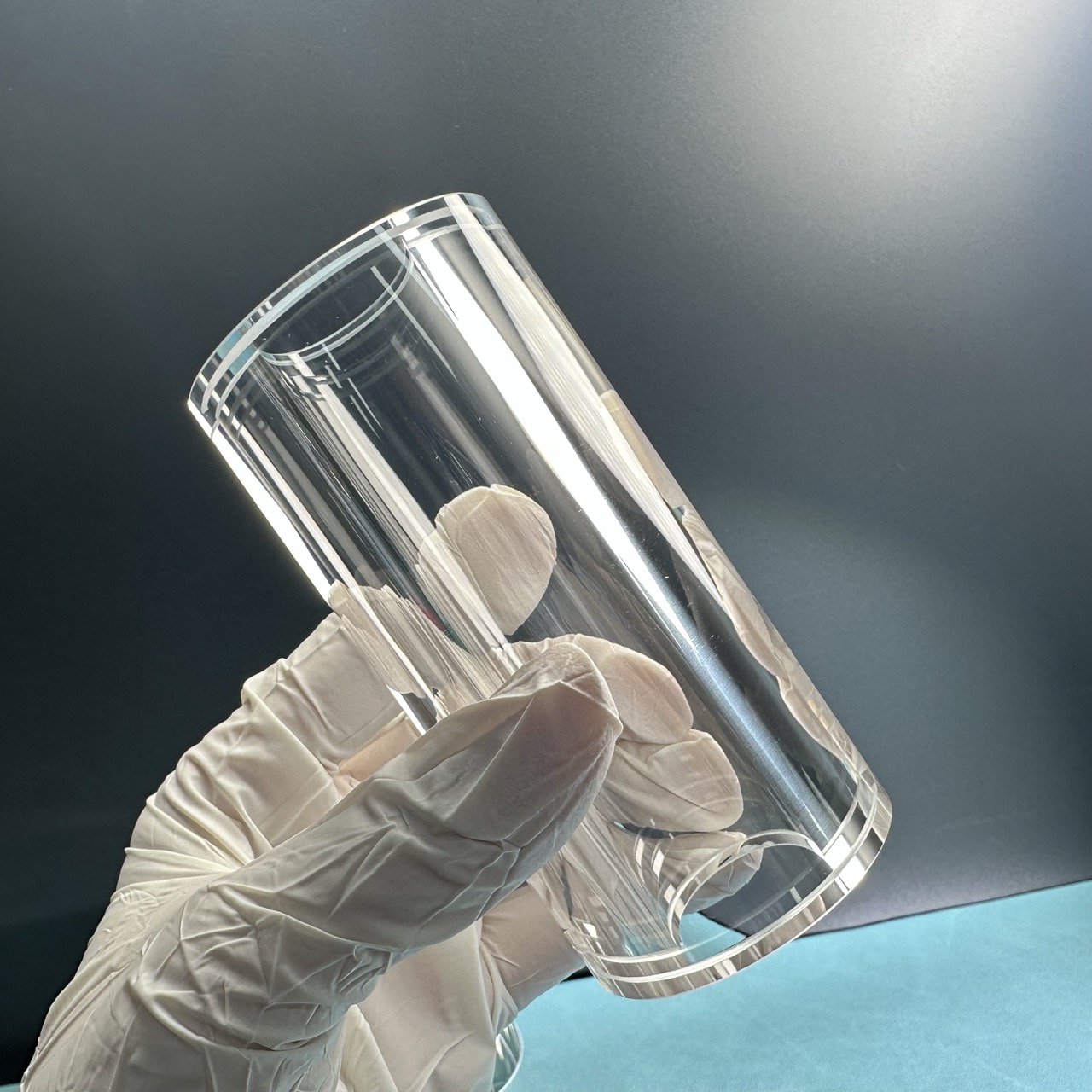

Sapphire Tubes Enhancing Thermocouple Reliability

Detailed Diagram

Introduction

In modern industry, accurate temperature monitoring is a critical part of process control, quality assurance, and safety systems. Thermocouples—widely used temperature sensors—are often exposed to challenging environments such as high temperatures, corrosive chemicals, vacuum systems, and plasma fields. Protecting these sensors effectively is essential for operational stability. Sapphire tubes, made from synthetic single-crystal aluminum oxide, have proven to be among the most reliable materials for such protection. This article explores the unique characteristics of sapphire tubes, their diverse uses, and in particular, their exceptional performance as thermocouple protection sheaths.

Superior Material for Demanding Applications

Sapphire is a crystalline form of aluminum oxide (Al₂O₃) and is ranked just below diamond in terms of hardness, scoring 9 on the Mohs scale. This exceptional hardness makes sapphire tubes highly resistant to scratching, abrasion, and mechanical impact, even under frequent or intense use.

Beyond mechanical strength, sapphire tubes are highly valued for their chemical resistance. They remain stable and inert in the presence of most acids, solvents, and reactive gases, including hydrogen fluoride, chlorine, and sulfur compounds. This allows them to function effectively in processes involving aggressive chemicals or plasma.

Additionally, sapphire's thermal performance is remarkable. It withstands prolonged exposure to temperatures as high as 2000°C while retaining its structural integrity. Its thermal conductivity supports rapid heat transfer, a feature especially important when used in temperature sensing systems.

Another important advantage is its optical transparency across ultraviolet, visible, and infrared wavelengths—from approximately 0.3 μm to 5 μm. This makes sapphire tubes suitable for optical sensing or combined thermal-optical monitoring systems.

Thermocouples and the Need for Protection

Thermocouples are essential components in a wide range of systems, from steel furnaces and turbine engines to semiconductor reactors and chemical process equipment. These devices generate a voltage based on the temperature difference between two dissimilar metals joined at one end. While thermocouples are versatile and robust, their direct exposure to heat, corrosive agents, and mechanical shock can drastically shorten their service life or degrade the accuracy of temperature readings.

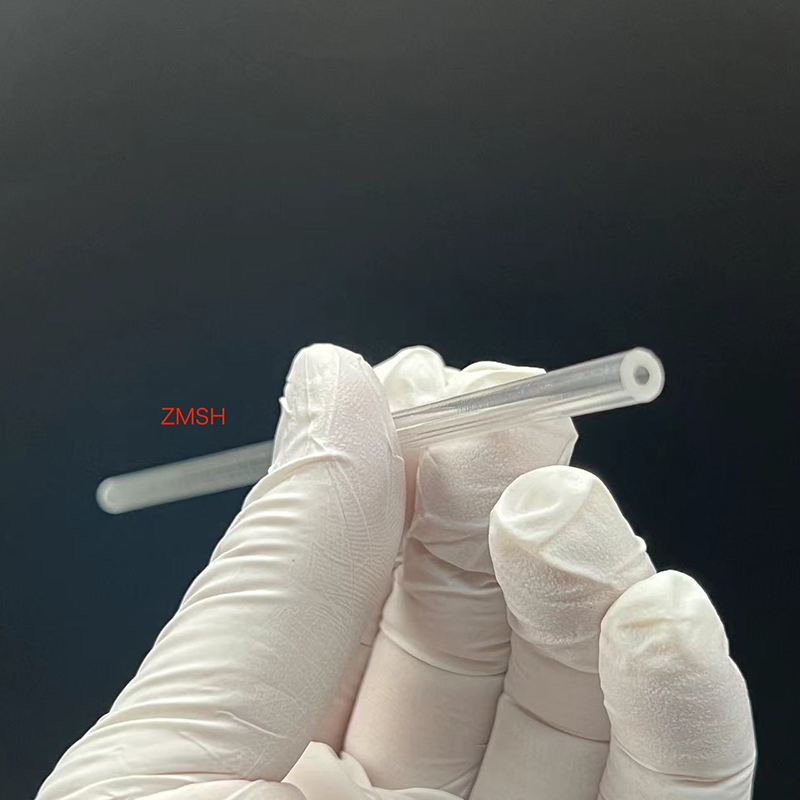

This is where sapphire tubes come into play as protective sheaths. By encasing the thermocouple inside a sapphire tube, the sensor is isolated from the harsh environment while still allowing efficient heat transfer. The result is a longer-lasting, more reliable sensor that maintains consistent accuracy even after prolonged exposure to aggressive operating conditions.

Sapphire’s thermal conductivity allows heat to reach the thermocouple quickly and uniformly, minimizing temperature lag and improving response time. Furthermore, its resistance to chemical attack ensures that the sensor is not compromised by residues, corrosion, or material buildup—issues that often plague metal or ceramic protective sleeves.

Use Cases in Temperature Monitoring

In high-temperature furnaces, sapphire tubes are commonly employed to shield thermocouples that monitor critical process conditions. Their chemical stability is essential in atmospheres rich in halogen gases, molten metals, or reactive vapors. For example:

-

Semiconductor Manufacturing: Sapphire sheaths protect thermocouples during epitaxial growth, wafer annealing, and doping processes, where clean environments and precise temperature control are vital.

-

Chemical Reactors: In catalytic reactions or corrosive vapor environments, sapphire tubes ensure long-term protection of temperature probes, eliminating contamination concerns.

-

Vacuum Furnaces: Sapphire tubes prevent oxidation and mechanical damage to thermocouples while operating under vacuum or low-pressure inert gases.

-

Combustion Systems: Jet engines, gas turbines, and industrial burners often rely on sapphire-protected thermocouples to monitor extreme heat levels for performance and safety optimization.

By using sapphire tubes, engineers are able to deploy thermocouples in conditions that would otherwise be too destructive for standard metal or glass sheaths. This widens the operating range of thermal monitoring systems and enhances their long-term performance.

Additional Industrial Applications of Sapphire Tubes

While thermocouple protection is a leading application, sapphire tubes are employed in many other advanced technologies:

-

High-Intensity Discharge (HID) Lamps: As envelope materials, sapphire tubes withstand intense heat and UV/IR radiation without clouding or softening.

-

Plasma Etching Chambers: Used as viewports and containment vessels due to their erosion resistance.

-

Inline Optical Sensing: Enable spectroscopy, imaging, and laser diagnostics through process pipelines without contaminating the medium.

-

Water Treatment and Medical Devices: Due to their bio-inertness and chemical resistance, sapphire tubes are ideal for systems that demand sterility and non-reactivity.

-

Laser Delivery Systems: Sapphire tubes guide high-power beams with minimal optical loss and maximal thermal stability.

These applications benefit from sapphire’s key properties—chemical inertness, optical clarity, high hardness, and thermal stability—across industries as diverse as aerospace, healthcare, petrochemicals, and electronics.

Core Physical Properties of Sapphire Tubes

-

Transparency Range: 0.3–5.0 μm (UV to IR), suitable for visual, laser, and spectroscopic use

-

Hardness: Mohs 9—resistant to abrasion and surface damage

-

Thermal Resistance: Stable up to 2030°C, with high conductivity for rapid heat exchange

-

Chemical Durability: Impervious to most solvents, acids, and alkalis

-

Electrical Insulation: Stable dielectric constant and low dielectric loss

-

Dimensional Stability: Resistant to thermal expansion and deformation under pressure

-

Plasma Resistance: Ideal for use in high-energy fields like PECVD or ion implantation

Summary and Benefits for Thermocouple Systems

-

Sapphire tubes bring a distinct combination of attributes that make them ideal for thermocouple protection:

-

Improved Accuracy: High thermal conductivity enables rapid response

-

Extended Durability: Resistance to wear and corrosion protects sensors long-term

-

Stable Performance: Maintains mechanical integrity even in cycling thermal loads

-

Non-contaminating: Chemically inert surfaces reduce error sources

-

Multifunctional Capability: Enables integration of optical sensing with thermal monitoring

-

Conclusion

-

Thermocouples are at the heart of temperature-sensitive systems, and their reliability depends heavily on the quality of their protective housing. Sapphire tubes, thanks to their extraordinary material properties, offer the best available combination of heat resistance, mechanical protection, and chemical purity. As industries continue to demand higher precision and durability in thermal systems, sapphire tube–protected thermocouples are becoming an essential solution for meeting those expectations.