Sapphire Tube KY method

Detailed Diagram

Overview

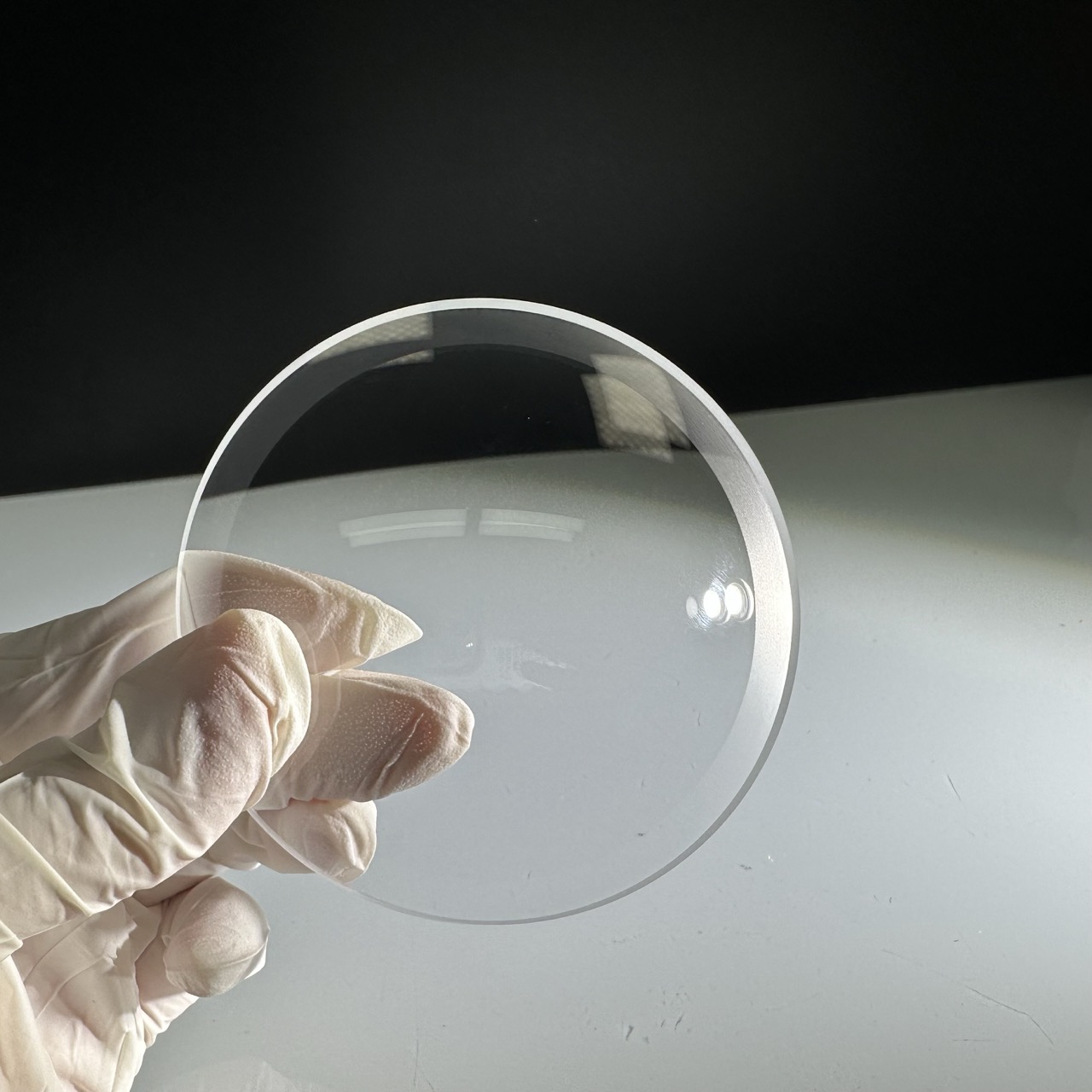

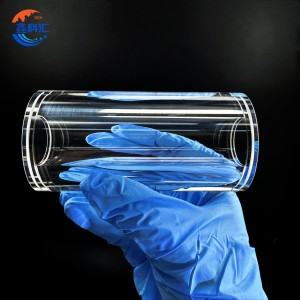

Sapphire tubes are precision-engineered components made from single-crystal aluminum oxide (Al₂O₃) with a purity exceeding 99.99%. As one of the hardest and most chemically stable materials in the world, sapphire offers a unique combination of optical transparency, thermal resistance, and mechanical strength. These tubes are widely used in optical systems, semiconductor processing, chemical analysis, high-temperature furnaces, and medical instruments, where extreme durability and clarity are essential.

Unlike ordinary glass or quartz, sapphire tubes maintain their structural integrity and optical properties even under high-pressure, high-temperature, and corrosive environments, making them the preferred choice for harsh or precision-critical applications.

Manufacturing Process

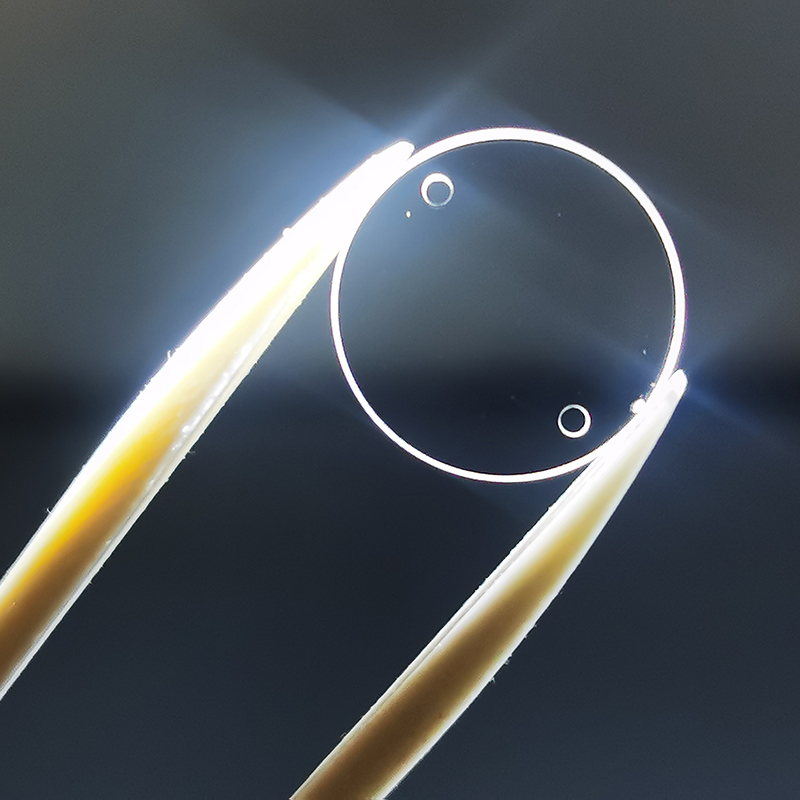

Sapphire tubes are typically produced using KY (Kyropoulos), EFG (Edge-defined Film-fed Growth), or CZ (Czochralski) crystal growth methods. The process begins with the controlled melting of high-purity alumina at over 2000°C, followed by the slow and uniform crystallization of sapphire into a cylindrical shape.

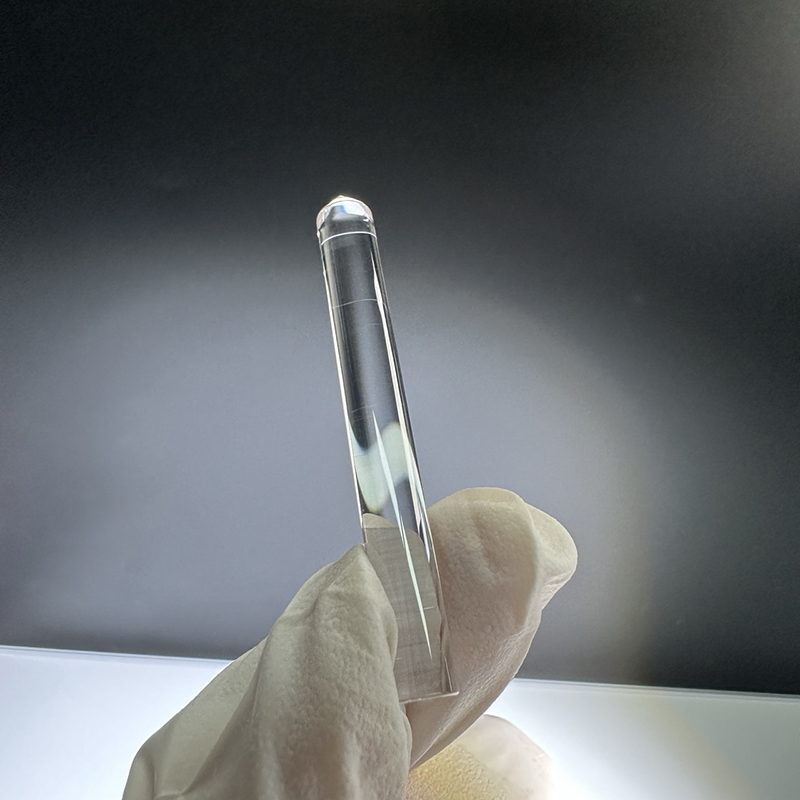

After growth, the tubes undergo CNC precision machining, internal/external polishing, and dimensional calibration, ensuring optical-grade transparency, high roundness, and tight tolerances.

EFG-grown sapphire tubes are especially suitable for long and thin geometries, while KY-grown tubes provide superior bulk quality for optical and pressure-resistant applications.

Key Features and Advantages

-

Extreme Hardness: Mohs hardness of 9, second only to diamond, offering excellent scratch and wear resistance.

-

Wide Transmission Range: Transparent from ultraviolet (200 nm) to infrared (5 μm), ideal for optical sensing and spectroscopic systems.

-

Thermal Stability: Withstands temperatures up to 2000°C in vacuum or inert atmospheres.

-

Chemical Inertness: Resistant to acids, alkalis, and most corrosive chemicals.

-

Mechanical Strength: Exceptional compressive and tensile strength, suitable for pressure tubes and protection windows.

-

Precision Geometry: High concentricity and smooth inner walls minimize optical distortion and flow resistance.

Typical Applications

-

Optical protection sleeves for sensors, detectors, and laser systems

-

High-temperature furnace tubes for semiconductor and material processing

-

Viewports and sight glasses in harsh or corrosive environments

-

Flow and pressure measurement under extreme conditions

-

Medical and analytical instruments requiring high optical purity

-

Lamp envelopes and laser housings where both transparency and durability are crucial

Technical Specifications (Typical)

| Parameter | Typical Value |

|---|---|

| Material | Single-crystal Al₂O₃ (Sapphire) |

| Purity | ≥ 99.99% |

| Outer Diameter | 0.5 mm – 200 mm |

| Inner Diameter | 0.2 mm – 180 mm |

| Length | up to 1200 mm |

| Transmission Range | 200–5000 nm |

| Working Temperature | up to 2000°C (vacuum/inert gas) |

| Hardness | 9 on Mohs scale |

FAQ

Q1: What is the difference between sapphire tubes and quartz tubes?

A: Sapphire tubes have much higher hardness, temperature resistance, and chemical durability. Quartz is easier to machine but cannot match sapphire’s optical and mechanical performance in extreme environments.

Q2: Can sapphire tubes be custom-machined?

A: Yes. Dimensions, wall thickness, end geometry, and optical polishing can all be customized based on customer requirements.

Q3: What crystal growth method is used for production?

A: We offer both KY-grown and EFG-grown sapphire tubes, depending on size and application needs.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.